Fiberglass Facing Chopped Strand Mat / Fiberglass Mat Roll Fabric CSM Factory in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Chopped Strand Mat /Fiberglass Mat Roll Fabric CSM Factory in China

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

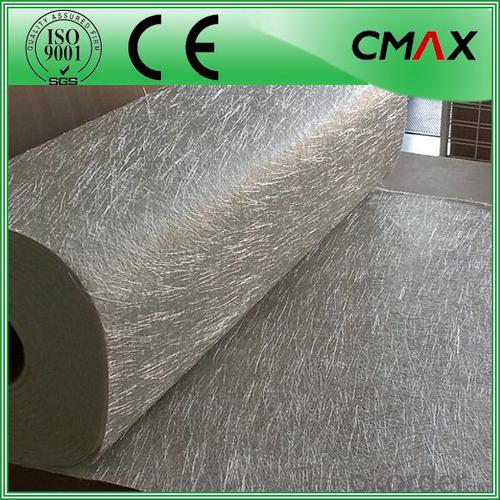

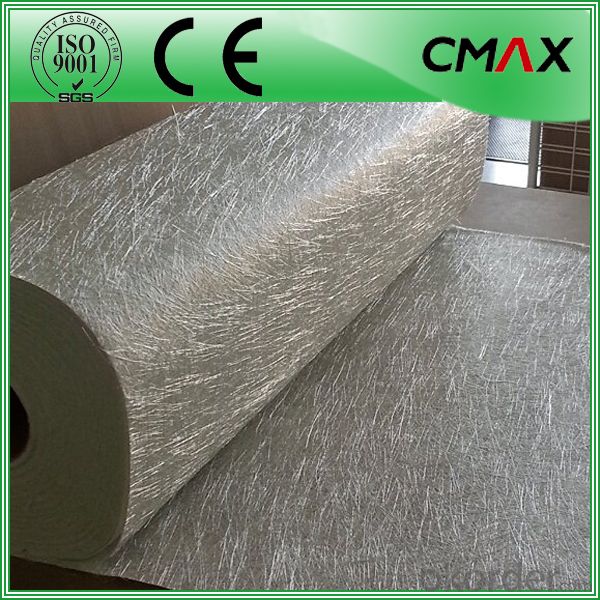

Products Shows:

Certificates:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton.

- Q: Is it possible to utilize black fiberglass tissue for the purpose of soundproofing?

- <p>Yes, black fiberglass tissue can be used for sound insulation. It is a popular material due to its lightweight, flexibility, and ability to absorb sound. Fiberglass is effective in reducing noise transmission by disrupting sound waves and preventing them from passing through. It is commonly used in walls, ceilings, and floors to improve acoustic performance in residential, commercial, and industrial settings. However, it's important to handle fiberglass with care due to its potential health risks and to ensure proper installation for maximum effectiveness.</p>

- Q: What is the texture or appearance of the surface of black fiberglass tissue?

- <p>The surface finish of black fiberglass tissue is typically smooth and matte. It is characterized by a uniform, non-reflective appearance with a slight texture that is often associated with the woven nature of the fiberglass. This finish can vary slightly depending on the specific manufacturing process and the intended application of the fiberglass tissue.</p>

- Q: What are the benefits of using fiberglass facing?

- There are several benefits of using fiberglass facing in various applications. Firstly, fiberglass facing offers excellent strength and durability, making it highly resistant to cracking, warping, and other forms of damage. This makes it ideal for use in construction and structural applications where strength and longevity are important factors. Additionally, fiberglass facing provides excellent thermal insulation properties. It has a low thermal conductivity, meaning it can effectively prevent heat transfer and maintain a consistent temperature in both hot and cold environments. This makes it a popular choice for insulation in buildings, HVAC systems, and other applications where energy efficiency is a key consideration. Another advantage of fiberglass facing is its resistance to moisture and corrosion. It is non-porous and does not absorb water, making it highly resistant to mold, mildew, and rot. This makes it a suitable material for use in damp or humid environments, such as bathrooms and kitchens. Furthermore, fiberglass facing is lightweight and easy to handle, making it convenient to install and transport. It can be easily cut and shaped to fit various surfaces and configurations, allowing for flexibility in design and installation. Its lightweight nature also reduces the strain on supporting structures, making it a cost-effective choice for construction projects. Lastly, fiberglass facing is available in a wide range of sizes, thicknesses, and finishes, allowing for customization to meet specific project requirements. It can be coated or laminated with different materials to enhance its performance, such as adding a vapor barrier or reflective surface. This versatility makes it suitable for a variety of applications in industries ranging from construction to transportation. In summary, the benefits of using fiberglass facing include its strength and durability, thermal insulation properties, resistance to moisture and corrosion, lightweight nature, and customization options. These advantages make it a popular choice in various industries where these characteristics are valued.

- Q: Is it possible to utilize black fiberglass tissue for the production of insulation materials?

- <p>Yes, black fiberglass tissue can be used to make insulation materials. It is a type of non-woven fabric made from glass fibers that are coated with a phenolic resin. This material is known for its excellent insulating properties, resistance to heat and electricity, and durability. It is commonly used in applications requiring thermal and acoustic insulation, such as in construction, automotive, and aerospace industries. However, it's important to note that proper safety measures should be taken when handling fiberglass due to its potential health risks if inhaled or if skin comes into prolonged contact.</p>

- Q: The user is asking if black fiberglass tape can be used to create a window screen or blind.

- <p>Yes, you can use black fiberglass tape to make a window screen or blind. Fiberglass tape is strong, durable, and resistant to weather and UV rays, making it suitable for outdoor use. To create a window screen, you can use the tape to secure a mesh material to a frame. For a blind, you might weave the tape in a pattern to create slats. However, ensure the tape is of high quality and the mesh is appropriately sized for the window. Always follow safety precautions when working with tools and materials.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other sound insulation materials, focusing on their properties and effectiveness.

- <p>Black fiberglass tissue is a type of sound insulation material known for its lightweight, flexibility, and high sound absorption capabilities. Compared to other materials, it offers excellent thermal insulation and resistance to moisture and fire. However, it may not be as dense or heavy-duty as some alternatives like mass-loaded vinyl or certain types of acoustic foam, which can provide better soundproofing in high-noise environments. Black fiberglass tissue is also sensitive to physical damage, which can reduce its effectiveness over time. It's important to consider the specific application and environmental factors when choosing the right sound insulation material.</p>

- Q: Is it possible to utilize black fiberglass tissue in the manufacturing of toys or games?

- <p>Yes, black fiberglass tissue can be used for making toys or games, but it's important to consider the material's properties and potential health risks. Fiberglass is a composite material that is strong, lightweight, and resistant to corrosion, making it suitable for certain types of toys or games that require durability. However, it's crucial to ensure that the fiberglass is properly treated and finished to avoid exposure to glass fibers, which can be harmful if inhaled or come into contact with skin. Additionally, it's essential to comply with safety regulations and consider the target audience for the toys or games, as fiberglass may not be appropriate for children's products due to these health concerns.</p>

- Q: What are the methods to keep black fiberglass tissue clean and free from dirt?

- <p>To prevent black fiberglass tissue from becoming dirty, follow these steps: 1. Regularly clean the surface with a soft brush or cloth to remove dust and debris. 2. Avoid direct exposure to harsh chemicals or substances that can stain or damage the fiberglass. 3. Use a protective cover or shield when working in areas where dirt or debris is likely to accumulate. 4. Apply a protective coating or sealant specifically designed for fiberglass to create a barrier against dirt and stains. 5. Regularly inspect the fiberglass for any signs of damage or wear, and address these issues promptly to prevent further dirt accumulation.</p>

- Q: This question asks about the ease of installation and maintenance of a flooring system constructed from black fiberglass scraps.

- <p>Installing and maintaining a flooring system made from black fiberglass scraps can be relatively easy, especially if the scraps are in good condition and the system is designed for easy installation. Fiberglass is known for its durability and resistance to moisture, which can reduce maintenance needs. However, the ease of installation can vary depending on the complexity of the system and the individual's experience with construction or flooring work. Proper sealing and finishing are crucial to prevent moisture absorption and to maintain the flooring's integrity. Regular cleaning and periodic inspections can help maintain the flooring system's condition.</p>

- Q: Is it possible to use black fiberglass tissue as an insulating material for walls in residential buildings?

- <p>Yes, black fiberglass tissue can be used for wall insulation in residential homes. It is a common insulating material known for its thermal and acoustic insulation properties. Black fiberglass is a type of glass wool that is treated with a black pigment to improve its UV resistance and durability. It is effective in reducing heat transfer and can help in maintaining a comfortable indoor temperature. However, it is important to ensure that it is installed correctly and safely, as fiberglass can cause skin and respiratory irritation if not handled properly.</p>

Send your message to us

Fiberglass Facing Chopped Strand Mat / Fiberglass Mat Roll Fabric CSM Factory in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords