Fiberglass Facing 600gsm Colored Spray Coating Tissue for Ceiling-600

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Tissue

Fiberglass Tissue is a kind of facing, which is made of by the white fiberglass tissue, and special production process.

Application of Fiberglass Tissue

Our black tissue are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also fiberglass tissue facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter

Advantage of Fiberglass Tissue

It is the high quality heat insulating and the invincible opponent of anti- condensation. The low and stable coefficient of heat conduction has good isolation effect.

The product has many advantages, such as light weight, heat insulation, shock absorption, sound absorption and noise reduction;

The product is easy to install and process and it also waterproof, seepage control, flame retardant.

The product also has many features, such as heat resistance, low temperature resistance, chemical resistance, ageing resistance etc.

Packing of Fiberglass Tissue

1. Waterproof paper then PVC shrinking Film

2. Water-Proof film only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

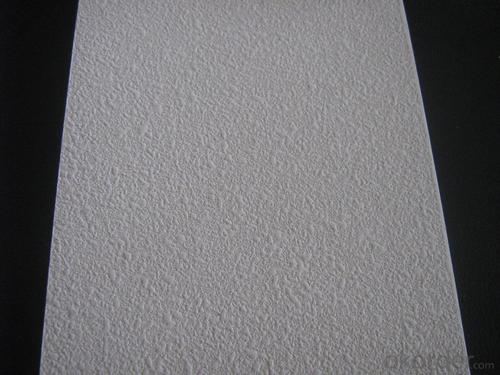

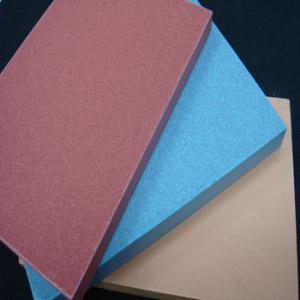

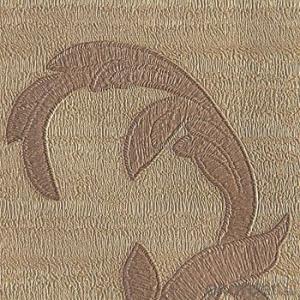

Pictures of Fiberglass Tissue

Specification of Fiberglass Tissue

Specification | ||

ITEM | UNIT | VALUE |

Type | C | |

Weight | g/m2 | 600±5 |

Thickness | mm | 0.40 |

Tensile Strength MD | n/125px | ≥130 |

Tensile Strength XD | n/125px | ≥90 |

Fiber Diameter | µ | 9 |

Fire Resistant Property | B1 | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is it possible to utilize recycled black fiberglass tissue for a future project?

- <p>Yes, you can use recycled black fiberglass tissue in your next project, provided it meets the quality and safety standards required for your specific application. Recycled fiberglass can be a sustainable and cost-effective alternative to new materials. Ensure that the recycled material has been properly processed to remove any contaminants and is free from degradation that could compromise its structural integrity. Always check with the supplier or manufacturer for any specific guidelines or certifications regarding the use of recycled materials in your project to ensure compliance with industry standards and safety regulations.</p>

- Q: This question asks for methods to properly maintain and care for black fiberglass tissue to ensure its longevity and appearance.

- <p>To maintain black fiberglass tissue, follow these steps: Regularly clean the surface with mild soap and water to remove dirt and grime. Avoid using harsh chemicals or abrasive cleaners that can damage the surface. Periodically inspect for any signs of wear or damage and address them promptly to prevent further deterioration. Apply a UV-resistant sealant or coating to protect the fiberglass from sun damage, which can cause fading and weakening over time. Store the tissue in a cool, dry place when not in use to prevent moisture damage. Regular maintenance will help preserve the color and integrity of the black fiberglass tissue.</p>

- Q: This question is asking about the distinctions between two types of fiberglass tissues: synthetic and natural. It seeks clarification on their properties and how they differ from each other.

- <p>Synthetic and natural fiberglass tissues differ primarily in their composition and manufacturing process. Synthetic fiberglass tissues are man-made, typically produced from glass fibers that are drawn from molten glass and then woven or matted together. They are known for their strength, durability, and resistance to various environmental factors. Natural fiberglass tissues, on the other hand, are derived from natural sources like minerals or plant fibers that are treated to mimic the properties of glass. They are often valued for their eco-friendliness and biodegradability. While synthetic fibers are more common due to their superior strength and versatility, natural fibers are gaining traction for their sustainability and lower environmental impact.</p>

- Q: This question asks about the positive environmental impacts associated with the use of black fiberglass tissue.

- <p>The environmental benefits of using black fiberglass tissue include its high resistance to UV radiation, which prolongs its lifespan and reduces waste. It's also lightweight, reducing transportation emissions. Black fiberglass tissue is often used in solar panel backings, aiding in energy production and reducing reliance on fossil fuels. Additionally, it's recyclable, contributing to a circular economy and reducing landfill waste. Its durability and resistance to harsh weather conditions also mean fewer replacements are needed, further minimizing environmental impact.</p>

- Q: What type of adhesive works best for adhering to black fiberglass tape?

- <p>For bonding to black fiberglass tape, a high-temperature resistant adhesive is recommended. Silicone-based adhesives are often suitable due to their high-heat tolerance and flexibility. Additionally, epoxy resins can also be used for their strong bonding properties. However, it's crucial to consider the specific application and environmental conditions, as different adhesives may perform better in various scenarios. Always check the manufacturer's recommendations and perform a small test before applying the adhesive to the entire surface.</p>

- Q: What are the ecological effects associated with the utilization of black fiberglass tissue?

- <p>The environmental impact of using black fiberglass tissue is primarily associated with its production and disposal. During production, it can release harmful chemicals and particulates into the air, contributing to air pollution. Additionally, fiberglass is not biodegradable, which means it persists in landfills and can leach chemicals into the soil and groundwater, potentially harming ecosystems. The dark color of black fiberglass may also absorb more heat, which could contribute to the urban heat island effect. However, it's important to note that the environmental impact can be mitigated through proper waste management and recycling programs, which are becoming more prevalent as awareness of environmental issues grows.</p>

- Q: Is it possible to utilize black fiberglass tissue in residential settings?

- <p>Yes, black fiberglass tissue can be used in residential applications. It is commonly utilized for insulation purposes, providing thermal and acoustic insulation. Black fiberglass is also used in the construction of walls, ceilings, and roofs to enhance energy efficiency and reduce noise pollution. However, it's important to ensure that it is installed correctly and safely, as improper handling can lead to health issues due to the potential release of fiberglass fibers.</p>

- Q: What are the common applications of black fiberglass tissue in the automotive industry?

- <p>Black fiberglass tissue, also known as black glass fiber cloth, is widely used in the automotive industry for various purposes. It is used in the production of reinforced plastic parts, such as body panels, hoods, and trunk lids, due to its strength and lightweight properties. It also serves as a heat insulator and soundproofing material in car interiors. Furthermore, it is utilized in the manufacturing of brake pads and clutch facings for its heat resistance and durability. Black fiberglass tissue enhances the structural integrity and performance of vehicles while contributing to weight reduction and fuel efficiency.</p>

- Q: Explain the distinction between high-density and low-density black fiberglass tissue in a few sentences.

- <p>High-density black fiberglass tissue is characterized by a higher concentration of glass fibers per unit volume, resulting in greater strength and durability. This type is often used in applications requiring high mechanical resistance, such as in aerospace or automotive components. Low-density black fiberglass tissue, on the other hand, has fewer glass fibers per unit volume, making it lighter and more flexible. It is commonly used in applications where weight is a concern, such as in the electronics industry for insulation or in construction materials. The main differences lie in their mechanical properties, thermal conductivity, and applications.</p>

- Q: Is it possible to utilize black fiberglass tissue as a material for creating a floor mat?

- <p>Yes, you can use black fiberglass tissue to make a floor mat. Fiberglass is known for its strength and durability, making it a suitable material for various applications, including floor mats. However, it's important to ensure that the mat is properly treated to be non-slip and comfortable to walk on. Fiberglass can be abrasive and may not provide the softness or cushioning that some users prefer. Additionally, consider the aesthetic appeal and whether the black color is appropriate for your intended use. Always follow safety guidelines when working with fiberglass to avoid skin and respiratory irritation.</p>

Send your message to us

Fiberglass Facing 600gsm Colored Spray Coating Tissue for Ceiling-600

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords