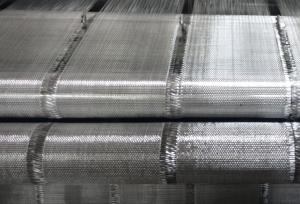

Fiberglass Mat Tissue Biaxial Stitched Combo Mat for Boat Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 20000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

E-glass stitched combo mat consists of two or more layers of fiberglass roving which are stitch-bonded.One layer of rovings and different layers of roving can be oriented differently and have different liner density.The roving specification,number of roving layers,mat width and roll diameter can be customized as per requirement.

Multi-axial series: At most 4 layers of roving can be stitched;however a layer of chopped strands(0g/㎡-500g/㎡)or composite materials can be added.The maximal width can be too inched.This product is used in blades of wind power turbines,boat manufacturing and sports devices.

2.Product Features

3.Product Specifications

Product no. | Overall Density | .+45°Roving Density | .-45°Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-BX300 | 306.01 | 150.33 | 150.33 | - | 5.35 |

E-BX450 | 456.33 | 225.49 | 225.49 | - | 5.35 |

E-BX600 | 606.67 | 300.66 | 300.66 | - | 5.35 |

E-BX800 | 807.11 | 400.88 | 400.88 | - | 5.35 |

E-BX1200 | 1207.95 | 601.3 | 601.3 | - | 5.35 |

E-BXM450/225 | 681.33 | 225.49 | 225.49 | 225 | 5.35 |

E-BXM600/225 | 830.75 | 300.2 | 300.2 | 225 | 5.35 |

E-BXM600/300 | 905.75 | 300.2 | 300.2 | 300 | 5.35 |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Can fiberglass mat tissue be used for architectural sculptures?

- Yes, fiberglass mat tissue can be used for architectural sculptures. Fiberglass mat tissue is a versatile material that is commonly used in various applications, including architectural sculptures. It is lightweight, flexible, and has excellent strength and durability properties, making it suitable for creating intricate and detailed sculptures. The fiberglass mat tissue can be molded and shaped into various forms, allowing artists and sculptors to bring their creative visions to life. It can be used to create sculptures of different sizes and shapes, whether it is a small decorative piece or a large-scale installation. Additionally, fiberglass mat tissue is resistant to weather and environmental conditions, making it suitable for outdoor sculptures that are exposed to harsh elements. It can withstand extreme temperature changes, UV radiation, and moisture, ensuring that the sculptures remain intact and visually appealing for a long time. Furthermore, the material can be easily painted and finished to achieve the desired aesthetic appearance. It can be coated with different types of paints, varnishes, or finishes to enhance the visual appeal and protect the surface of the sculpture from potential damage. Overall, fiberglass mat tissue provides artists and sculptors with a reliable and versatile medium for creating architectural sculptures. Its strength, durability, and adaptability make it an excellent choice for bringing artistic visions to life in the architectural realm.

- Q: How is fiberglass mat tissue used in the production of agricultural equipment?

- Fiberglass mat tissue, a thin fiberglass material, plays a vital role in agricultural equipment production. It is mainly used as a reinforcement material during the manufacturing process of agricultural machinery like tractors, harvesters, and sprayers. One significant use of fiberglass mat tissue in agricultural equipment production is constructing structural components. The tissue reinforces body panels and chassis, providing strength and durability to the machinery. This reinforcement enhances the overall structural integrity and load-bearing capacity of the equipment, making it more reliable and capable of withstanding harsh conditions. Furthermore, fiberglass mat tissue is employed in agricultural equipment production due to its corrosion resistance properties. Agricultural machinery is often exposed to chemicals, fertilizers, and the elements. By incorporating fiberglass mat tissue in the manufacturing process, the machinery becomes more resistant to corrosion. This increases its lifespan and reduces maintenance costs. In addition, fiberglass mat tissue is utilized to enhance insulation and soundproofing capabilities in agricultural equipment. By adding layers of the tissue between panels and components, the machinery becomes better insulated against temperature fluctuations, reducing energy loss and improving efficiency. Moreover, the tissue helps dampen noise and vibration, creating a quieter and more comfortable working environment for operators. To summarize, fiberglass mat tissue is a vital component in agricultural equipment production. Its reinforcement, corrosion resistance, insulation, and soundproofing properties contribute to the overall performance, durability, and efficiency of agricultural machinery, making it an indispensable material in this industry.

- Q: Is fiberglass mat tissue resistant to alkalis?

- Indeed, fiberglass mat tissue exhibits resistance against alkalis, making it a suitable option for construction and industrial purposes that involve interactions with alkaline materials like cement or concrete. Its design specifically caters to providing exceptional durability and longevity within such environments, thanks to its high resistance against alkalis. This durability stems from the chemical composition and structure of the fiberglass, which enables it to withstand the corrosive impacts of alkalis without any degradation. Hence, fiberglass mat tissue emerges as a dependable choice for projects requiring exposure to alkalis.

- Q: Can fiberglass mat tissue be used for making insulation blankets?

- Yes, fiberglass mat tissue can be used for making insulation blankets. Fiberglass mat tissue is a lightweight and flexible material that is commonly used in insulation applications. It offers excellent thermal insulation properties, as well as resistance to fire, moisture, and chemicals. Additionally, fiberglass mat tissue is easy to handle and install, making it an ideal choice for creating insulation blankets that can be used in various industries, such as construction, automotive, and aerospace.

- Q: What is the flexibility of fiberglass mat tissue at low temperatures?

- The flexibility of fiberglass mat tissue at low temperatures is generally maintained, as fiberglass has low thermal expansion and contraction properties, allowing it to retain its flexibility even in cold conditions.

- Q: How does the density of fiberglass mat tissue impact its performance?

- The density of fiberglass mat tissue directly affects its performance. Higher density mat tissue is typically stronger and more durable, providing better structural support and resistance to impact. On the other hand, lower density mat tissue is lighter and more flexible, making it suitable for applications where weight and flexibility are important factors. Ultimately, the density of fiberglass mat tissue plays a crucial role in determining its strength, flexibility, and overall performance.

- Q: Is fiberglass mat tissue suitable for chemical storage tanks?

- Chemical storage tanks often find fiberglass mat tissue to be a suitable choice. The chemical resistance properties of fiberglass itself are well-known, which is why it is commonly used for storing a wide variety of chemicals. Moreover, fiberglass mat tissue is typically employed as a reinforcement layer during the construction of fiberglass tanks, providing them with added strength and durability. Nevertheless, it is important to consider the specific chemical being stored. Certain highly corrosive or reactive chemicals may necessitate the use of more specialized materials or additional protective coatings to ensure the tank's integrity. Therefore, it is always advisable to seek guidance from a professional engineer or manufacturer in order to identify the most appropriate materials for a given chemical storage application.

- Q: Can fiberglass mat tissue be used for insulation in pharmaceutical storage areas?

- No, fiberglass mat tissue is not suitable for insulation in pharmaceutical storage areas. This material may release particles or fibers that can contaminate the pharmaceutical products, which could compromise their quality and safety. It's essential to use insulation materials that are specifically designed and approved for pharmaceutical storage areas to ensure optimal conditions and adherence to regulatory standards.

- Q: What is the thermal resistance of fiberglass mat tissue?

- The thermal resistance of fiberglass mat tissue depends on various factors such as the thickness of the mat, the density of the fibers, and the presence of any additional materials or coatings. Generally, fiberglass has a low thermal resistance, meaning it is a good conductor of heat. However, when used as insulation, the thickness and density of the fiberglass mat can increase its thermal resistance, making it more effective at reducing heat transfer. It is important to note that specific values for thermal resistance can vary depending on the specific product and application, so it is recommended to consult the manufacturer's specifications for accurate information.

- Q: How does the thickness of fiberglass mat tissue affect its performance?

- The thickness of fiberglass mat tissue directly affects its performance. A thicker tissue provides increased strength, durability, and insulation properties. It also enhances the material's ability to absorb impact and resist damage. Thinner tissues, on the other hand, offer greater flexibility and easier handling. Therefore, choosing the appropriate thickness of fiberglass mat tissue is crucial to achieve desired performance characteristics in various applications.

Send your message to us

Fiberglass Mat Tissue Biaxial Stitched Combo Mat for Boat Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 20000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords