Fiberglass Mat Tissue Reinforced Aluminum Foil Mesh Glass Wool Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Petrochemical industry -- heat insulation and sound absorption of equipments for petroleum industry, power industry and chemical industry.

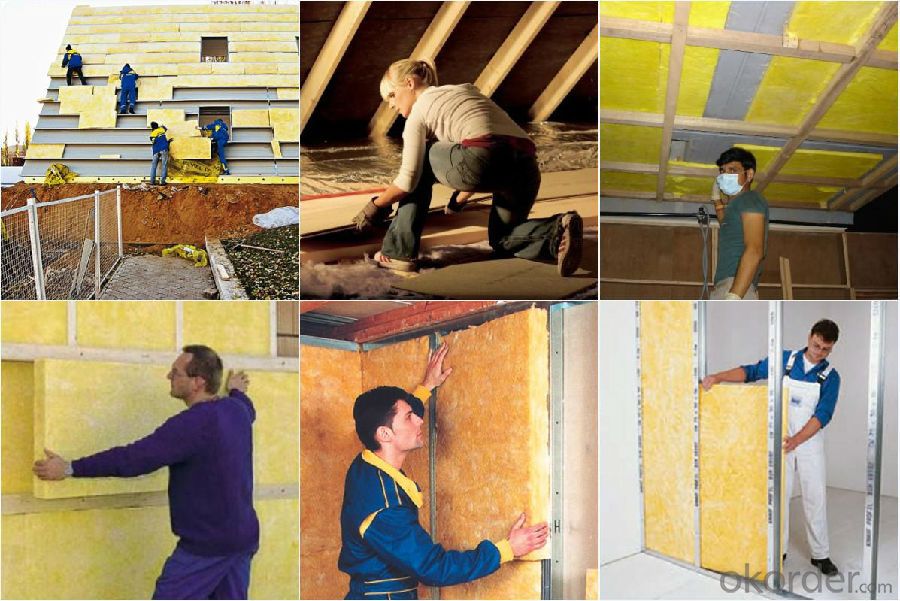

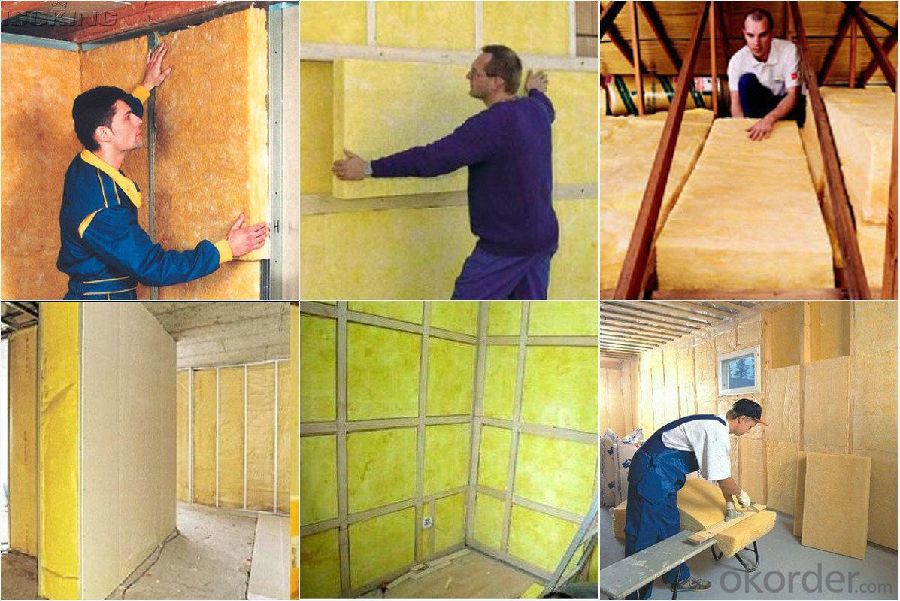

Construction industry -- heat insulation and sound absorption of partition, curtain wall, roofs and fences for construction.

Mining industry -- heat preservation and fireproof for industrial kiln, oven, large-caliber storage tank and shipping.

2.Main features of Glass Wool Blanket:

1. Small coefficient of heat conductivity and good capability of heating preservation

2. Outstanding effect of energy-saving.

3. Excellent fireproof capability. Excellent sound absorption and sound insulation capability.

4. Green building materials and no harm for body.

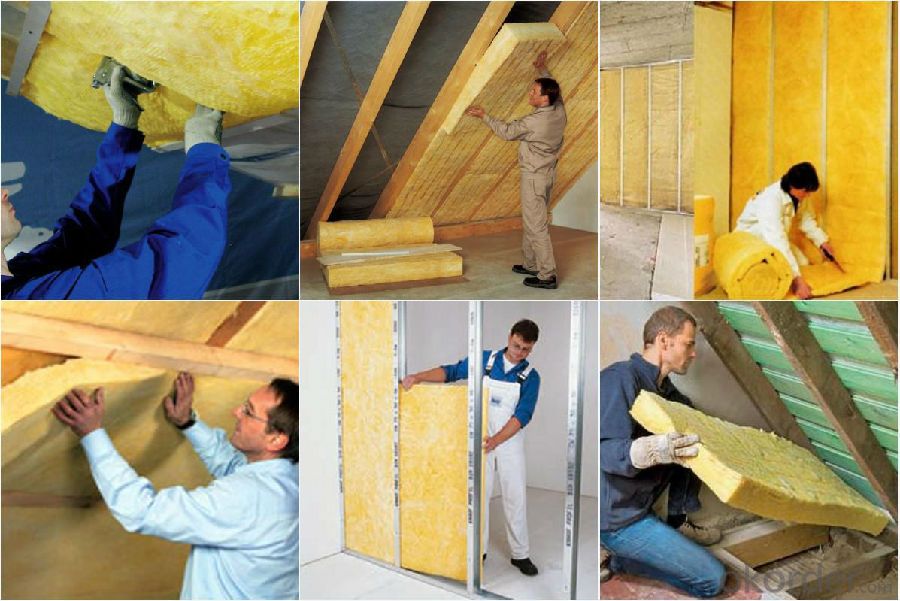

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can fiberglass mat tissue be used for insulation in oil refineries?

- Yes, fiberglass mat tissue can be used for insulation in oil refineries. It is commonly used due to its excellent thermal insulation properties, resistance to high temperatures, and resistance to chemical corrosion.

- Q: Can fiberglass mat tissue be used for insulation in refrigeration systems?

- Indeed, insulation in refrigeration systems can be accomplished by employing fiberglass mat tissue. Fiberglass, renowned for its remarkable thermal characteristics and moisture resistance, is a prevalent choice for insulation purposes. Specifically engineered to provide insulation, fiberglass mat tissue finds frequent application in the construction of refrigeration systems. Its purpose is to reduce heat transfer and uphold the desired temperature within the system. Moreover, fiberglass possesses the advantages of being lightweight, long-lasting, and easily installable, rendering it a favored option for refrigeration system insulation.

- Q: Can fiberglass mat tissue be used for insulation in underground pipelines?

- Yes, fiberglass mat tissue can be used for insulation in underground pipelines. Fiberglass mat tissue is known for its excellent thermal insulation properties and is commonly used in various industrial applications, including underground pipelines. It provides insulation by preventing heat transfer between the pipeline and the surrounding environment, thus helping to maintain the desired temperature inside the pipeline. Additionally, fiberglass mat tissue is resistant to moisture, chemicals, and corrosion, making it an ideal choice for underground applications where pipelines are exposed to harsh conditions. Overall, fiberglass mat tissue is a reliable and effective insulation material for underground pipelines.

- Q: Can fiberglass mat tissue be used for wind turbine nacelles?

- Yes, fiberglass mat tissue can be used for wind turbine nacelles. Fiberglass mat tissue is a lightweight and durable material that is commonly used in various industries, including wind energy. It is highly suitable for wind turbine nacelles due to its excellent mechanical properties, such as high strength, stiffness, and resistance to corrosion and fatigue. Additionally, fiberglass mat tissue can be easily molded into complex shapes, making it ideal for fabricating the intricate components of wind turbine nacelles. Overall, using fiberglass mat tissue in wind turbine nacelles helps to enhance their structural integrity, reduce weight, and improve the overall performance and longevity of the turbines.

- Q: Is fiberglass mat tissue resistant to fading?

- Fiberglass mat tissue is generally not resistant to fading. Fading occurs when a material loses its original color or brightness due to exposure to sunlight or other environmental factors. While fiberglass itself is known for its durability and resistance to weathering, the mat tissue used in fiberglass products is often susceptible to fading over time. This can be attributed to the binder or resin used to hold the fiberglass fibers together, as well as the pigments or dyes used to color the tissue. Exposure to UV rays and other outdoor elements can cause these components to break down and fade, resulting in a loss of color intensity or brightness. Therefore, if maintaining the aesthetic appearance of a fiberglass product is important, additional protective measures such as applying a UV-resistant coating or using pigments specifically designed for outdoor use may be necessary.

- Q: What is the thermal conductivity of fiberglass mat tissue?

- The thermal conductivity of fiberglass mat tissue is typically low, ranging from 0.03 to 0.05 W/m·K. This means that fiberglass mat tissue is a good insulator and can effectively resist the transfer of heat. Its low thermal conductivity makes it suitable for applications such as thermal insulation in buildings, industrial equipment, and appliances.

- Q: What is the flexibility of fiberglass mat tissue at low temperatures?

- The flexibility of fiberglass mat tissue at low temperatures is generally maintained, as fiberglass has low thermal expansion and contraction properties, allowing it to retain its flexibility even in cold conditions.

- Q: What is the expected lifespan of fiberglass mat tissue in chemical storage applications?

- The expected lifespan of fiberglass mat tissue in chemical storage applications can vary depending on several factors. These factors include the type of chemicals being stored, the concentration of the chemicals, and the specific conditions of the storage environment. Fiberglass mat tissue is commonly used in chemical storage applications due to its excellent resistance to corrosion and its ability to provide structural reinforcement. However, it is important to note that fiberglass mat tissue is not completely impervious to chemical degradation. In general, fiberglass mat tissue can withstand a wide range of chemicals and can have a relatively long lifespan when properly maintained. It is typically designed to last for several years, with some manufacturers offering warranties ranging from 10 to 20 years. However, certain aggressive chemicals or extreme storage conditions may accelerate the degradation process of fiberglass mat tissue. Chemicals with high acidity or alkalinity, extreme temperatures, or prolonged exposure to UV radiation can potentially reduce the lifespan of the material. To ensure the maximum lifespan of fiberglass mat tissue in chemical storage applications, it is essential to carefully select the appropriate type of fiberglass mat tissue that is specifically designed for the intended chemicals and storage conditions. Regular inspections, maintenance, and proper handling of the chemicals can also help extend the lifespan of the material. Ultimately, it is recommended to consult with the manufacturer or a qualified engineer to determine the expected lifespan of fiberglass mat tissue in a specific chemical storage application, as they can provide more accurate information based on the specific circumstances.

- Q: What is the expected lifespan of fiberglass mat tissue in cryogenic applications?

- The lifespan of fiberglass mat tissue in cryogenic applications may vary, depending on factors like material quality, specific cryogenic environment, and maintenance and handling practices. Fiberglass mat tissue is renowned for its exceptional insulation properties and ability to withstand extreme temperatures. It is commonly utilized in cryogenic applications to offer thermal insulation and structural support. Under well-maintained and controlled cryogenic conditions, fiberglass mat tissue can endure for several decades. However, it should be noted that exposure to intense thermal cycling, mechanical stress, and chemicals can impact its performance and lifespan. To ensure the longevity of fiberglass mat tissue in cryogenic applications, it is crucial to conduct regular inspections, maintenance, and adhere to the manufacturer's guidelines. Promptly addressing any signs of degradation or damage is also recommended to prevent potential issues or failures.

- Q: Can fiberglass mat tissue be used for repairing fiberglass tanks?

- Fiberglass tanks can be repaired using fiberglass mat tissue. This type of tissue is a flexible and thin material commonly utilized in the construction and fixing of fiberglass items. Its purpose is to provide reinforcement and enhance the strength of the repaired sections. By using the appropriate resin, cracks, holes, or damaged areas in fiberglass tanks can be effectively restored with fiberglass mat tissue. Nonetheless, it is crucial to execute the repair in a meticulous and expert manner, adhering to the manufacturer's instructions and guidelines. Seeking advice from a fiberglass repair specialist or expert is highly recommended to achieve the optimal repair outcome.

Send your message to us

Fiberglass Mat Tissue Reinforced Aluminum Foil Mesh Glass Wool Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords