Fiberglass Mat Tissue Glasswool Blanket Fire Protection Glass Wool Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property.

It is widely used for heat insulation and sound absorption in industrial workshops, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc.

2.Main features of Glass Wool Blanket:

• Sound absorption and noise reduction; it can effectively prevent sound from spreading.

• Grade A1 incombustible materials.

• Easy for construction; cutting at will.

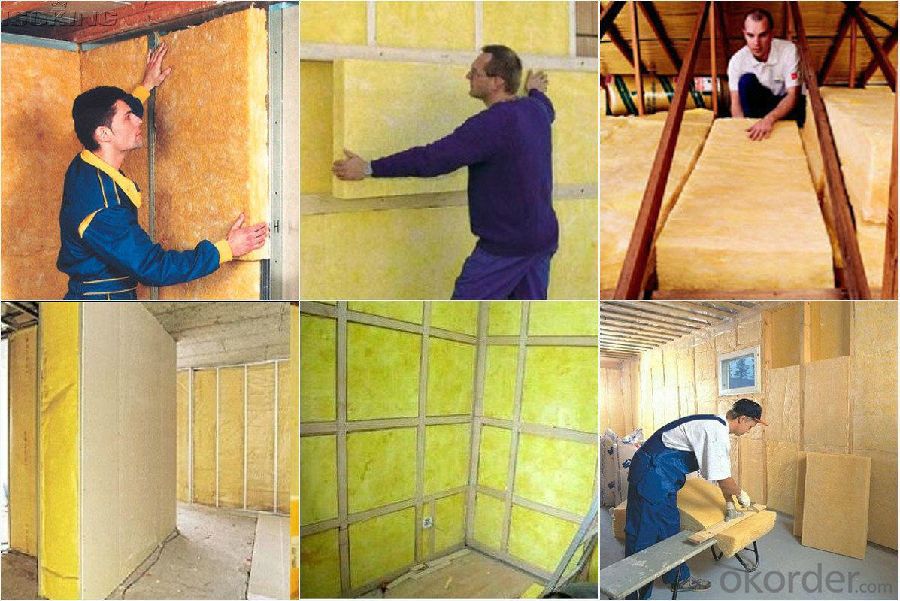

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can fiberglass mat tissue be used for architectural sculptures?

- Certainly! Fiberglass mat tissue is an ideal choice for architectural sculptures. This versatile material finds extensive use across various applications, including the creation of architectural sculptures. Renowned for its lightweight nature, flexibility, and exceptional strength and durability properties, it proves itself as an excellent option for crafting intricate and detailed sculptures. The beauty of fiberglass mat tissue lies in its ability to be molded and shaped into various forms, enabling artists and sculptors to transform their creative visions into reality. Regardless of the sculpture's size or shape, this material allows for utmost creativity, whether it be a small decorative piece or a large-scale installation. Moreover, fiberglass mat tissue boasts resistance against adverse weather conditions and environmental elements, rendering it suitable for outdoor sculptures. Its capacity to withstand extreme temperature fluctuations, UV radiation, and moisture ensures the sculptures' integrity and aesthetic appeal remain unscathed for an extended period. To further enhance the desired aesthetic appearance, fiberglass mat tissue can be effortlessly painted and finished. The material readily accepts various paints, varnishes, or finishes, providing artists with the means to elevate the visual appeal and safeguard the sculpture's surface against potential damage. All in all, fiberglass mat tissue serves as a reliable and versatile medium for artists and sculptors alike to create architectural sculptures. Its robustness, durability, and adaptability make it an exceptional choice for translating artistic visions into tangible masterpieces within the realm of architecture.

- Q: What is the dimensional stability of fiberglass mat tissue?

- The dimensional stability of fiberglass mat tissue refers to its ability to maintain its size and shape under various conditions. Fiberglass mat tissue is known for its excellent dimensional stability, making it highly resistant to shrinking, expanding, or warping. This stability is achieved through the manufacturing process, which involves bonding glass fibers together using a binder material. This binder not only ensures the integrity of the mat tissue but also helps it maintain its dimensional stability over time. Additionally, the inherent properties of fiberglass, such as its high strength and stiffness, contribute to its exceptional dimensional stability. These characteristics make fiberglass mat tissue a popular choice in various applications, including construction, automotive, and aerospace industries, where consistent dimensions are crucial for optimal performance and durability.

- Q: Is fiberglass mat tissue suitable for architectural applications?

- Yes, fiberglass mat tissue is suitable for architectural applications. It is commonly used as a reinforcing material for various architectural elements such as building facades, roofs, walls, and insulation. It provides strength, durability, and thermal insulation, making it an ideal choice for architectural projects.

- Q: Is fiberglass mat tissue suitable for insulation in cold storage facilities?

- Fiberglass mat tissue can be a suitable insulation material for cold storage facilities. Fiberglass is known for its excellent thermal insulation properties, which can effectively prevent heat transfer and maintain low temperatures in the storage area. Additionally, fiberglass is resistant to moisture and does not absorb water, which is important in cold storage facilities where condensation and moisture can be prevalent. The fiberglass mat tissue can be easily installed and provides a cost-effective solution for insulating the walls, ceilings, and floors of cold storage facilities. Overall, fiberglass mat tissue can effectively contribute to maintaining the desired cold temperatures and preventing any thermal leaks in these facilities.

- Q: Can fiberglass mat tissue be used for wind turbine nacelles?

- Yes, fiberglass mat tissue can be used for wind turbine nacelles. It is a commonly used material in the manufacturing of nacelles due to its lightweight, high strength, and excellent weather resistance properties.

- Q: Is fiberglass mat tissue resistant to moisture?

- Yes, fiberglass mat tissue is resistant to moisture. Fiberglass mat tissue is made from tightly woven strands of glass fibers, which are then bonded together with a resin. This resin creates a barrier that prevents moisture from penetrating the tissue. As a result, fiberglass mat tissue is highly resistant to moisture and can be used in applications where exposure to water or high humidity is expected. Additionally, the moisture resistance of fiberglass mat tissue helps prevent the growth of mold or mildew, making it a suitable choice for damp environments.

- Q: Can fiberglass mat tissue be used for bridge deck rehabilitation?

- Yes, fiberglass mat tissue can be used for bridge deck rehabilitation. It is a commonly used material due to its durability, strength, and resistance to corrosion. Additionally, it provides a smooth surface for the bridge deck, helps in preventing cracking and deterioration, and improves the overall structural integrity of the bridge.

- Q: How is fiberglass mat tissue used in the production of sports equipment?

- Fiberglass mat tissue is used in the production of sports equipment as it provides strength, flexibility, and durability to the final product. It is commonly used as a reinforcement material in the manufacturing of sports equipment such as snowboards, surfboards, hockey sticks, and tennis rackets. The fiberglass mat tissue is typically layered with resin and other materials, forming a composite structure that enhances the overall performance and longevity of the sports equipment.

- Q: Is fiberglass mat tissue suitable for sound absorption?

- Fiberglass mat tissue is indeed appropriate for sound absorption. Its exceptional acoustic properties make it a highly efficient material for decreasing noise levels and enhancing sound quality in different settings. The fibrous composition of the mat tissue offers a large surface area capable of absorbing sound waves and converting them into heat energy. This renders it an optimal choice for soundproofing walls, ceilings, and floors in buildings, as well as for automotive, industrial, and marine applications. Moreover, fiberglass mat tissue is lightweight, simple to install, and possesses excellent durability and fire resistance, further augmenting its aptness for sound absorption objectives.

- Q: What are the different grades of fiberglass mat tissue available?

- In the market, you can find various grades of fiberglass mat tissue. These grades differ in terms of their weight, thickness, and strength. The most popular grades include lightweight, medium-weight, and heavyweight fiberglass mat tissue. When it comes to lightweight fiberglass mat tissue, it is generally thinner and lighter compared to other grades. It is commonly used in situations where flexibility and easy handling are important. This grade is suitable for projects like laminating lightweight structures, making molds, and doing repairs. If you're looking for a versatile option that offers a balance between strength and flexibility, medium-weight fiberglass mat tissue is the way to go. It is widely used in boat building, automotive repairs, and general fiberglass reinforcement. This grade provides sufficient strength while still being manageable to work with. On the other hand, if you need superior strength and durability, heavyweight fiberglass mat tissue is the grade for you. It is the thickest and heaviest grade available in the market. This grade is perfect for applications that require high structural integrity, such as construction, aerospace, and marine industries. Apart from these standard grades, there may be variations and special grades available depending on the manufacturer and the specific requirements of your project. It is crucial to consult with a supplier or manufacturer to determine the most suitable grade of fiberglass mat tissue for your particular application.

Send your message to us

Fiberglass Mat Tissue Glasswool Blanket Fire Protection Glass Wool Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords