Fiberglass Mat Tissue Glass Wool Insulation with Aluminum Foil Faced

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

glass wool is made by adopting unique centrifugal technology and adding environmental adhesives of thermosetting resinsbased into molten glass fibrosis. It is a kind of elastic glass fiber product made of glass fiber with diameter of only a few microns, and we can also choose moisture-proof facing on-line compound according to customers' requirements. Because of a large number of tiny air interspaces, it has the functions of heat insulation, sound absorption, safe guarding and etc, so it is the best materials of heat insulation and sound absorption in construction.

2.Main features of Glass Wool Blanket:

• Unique technology; rebound degree after compressive packing is up to 99.2%.

• Soft and long glass fibers can maximally lessen flying catkins in the construction.

• Sound absorption and noise reduction; it can effectively prevent sound from spreading.

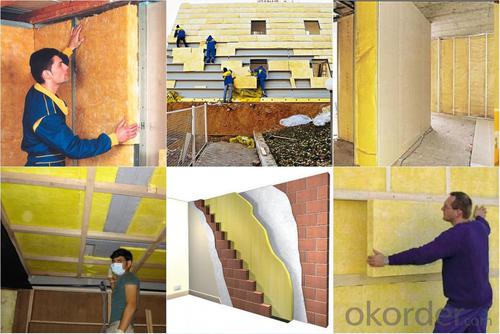

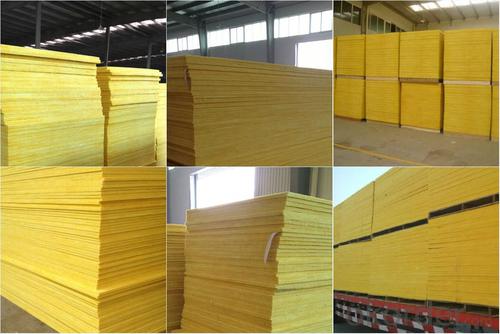

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is fiberglass mat tissue suitable for insulation in wastewater treatment plants?

- Yes, fiberglass mat tissue is suitable for insulation in wastewater treatment plants. Wastewater treatment plants often require insulation to prevent heat loss, control temperature, and protect against corrosion. Fiberglass mat tissue is a commonly used material for insulation in these facilities due to its high thermal resistance, excellent chemical resistance, and durability. It can effectively insulate pipes, tanks, and other equipment in wastewater treatment plants, ensuring optimal performance and energy efficiency. Additionally, fiberglass mat tissue is lightweight, easy to install, and cost-effective, making it a practical choice for insulation in these harsh environments.

- Q: What are the different reinforcement orientations available for fiberglass mat tissue?

- Fiberglass mat tissue offers several reinforcement orientations, each intended for specific purposes in different applications. One common orientation is unidirectional reinforcement, where fibers align in one direction. This orientation provides great strength and stiffness in that alignment, making it suitable for applications requiring resistance to tension or bending forces in a single direction. Another orientation is bidirectional reinforcement, where fibers align in two perpendicular directions. This orientation provides equal strength and stiffness in both directions, making it ideal for applications needing resistance to tension and compression forces. Structural components like panels, pipes, and tanks commonly employ bidirectional reinforcement. A third orientation is randomly oriented reinforcement, where fibers distribute randomly. This orientation offers isotropic properties, meaning it provides similar strength and stiffness in all directions. Random reinforcement is often used in applications requiring uniform strength and flexibility, like automotive parts, boat hulls, and sporting goods. Furthermore, hybrid reinforcement orientations are available, combining different fibers or orientations to meet specific performance requirements. These hybrids offer a combination of strength, stiffness, flexibility, and other desired properties, making them suitable for a wide range of applications. Overall, the choice of reinforcement orientation for fiberglass mat tissue depends on the application's specific requirements, including desired mechanical properties, forces to be resisted, and other performance considerations.

- Q: Can fiberglass mat tissue be used for composite pipe manufacturing?

- Yes, fiberglass mat tissue can be used for composite pipe manufacturing. Fiberglass mat tissue is a type of reinforcement material that is commonly used in the production of composite pipes. It provides strength and durability to the pipes, making them suitable for various applications. The fiberglass mat tissue is typically impregnated with a resin, such as polyester or epoxy, which helps to bind the fibers together and create a solid structure. This reinforcement material is known for its lightweight properties and excellent corrosion resistance, making it an ideal choice for composite pipe manufacturing. Additionally, fiberglass mat tissue can be easily molded into different shapes and sizes, allowing for the production of pipes with varying diameters and lengths. Overall, the use of fiberglass mat tissue in composite pipe manufacturing offers numerous advantages, including enhanced strength, durability, and resistance to harsh environmental conditions.

- Q: What are the main applications of fiberglass mat tissue?

- The main applications of fiberglass mat tissue include reinforcement in the construction industry for roofing, walls, and flooring, as well as insulation in thermal and acoustic systems. It is also used in the manufacturing of automotive parts, boats, and pipes for their strength and durability. Additionally, it finds use in the production of printed circuit boards and as a filtration medium in air and liquid filtration systems.

- Q: Can fiberglass mat tissue be used for pipe wrapping?

- Pipe wrapping can indeed utilize fiberglass mat tissue, a lightweight and flexible material extensively employed in reinforcing and safeguarding various structures, including pipes. The primary purpose of fiberglass mat tissue is to enhance the pipes' strength and durability, thereby rendering them more resilient to damage and corrosion. Wrapping the pipe with fiberglass mat tissue is a simple process that creates a protective layer, effectively preventing leaks and prolonging the pipe's lifespan. Moreover, fiberglass mat tissue is renowned for its remarkable insulation properties, contributing to the maintenance of the contents' temperature as they flow through the pipe. Consequently, fiberglass mat tissue serves as a suitable material for pipe wrapping and finds widespread application across diverse industries.

- Q: What is the thermal conductivity of fiberglass mat tissue?

- Fiberglass mat tissue typically exhibits a low thermal conductivity, which falls within the range of 0.03 to 0.05 W/m·K. Consequently, it serves as an excellent insulator, effectively impeding the flow of heat. Its favorable insulative properties render it suitable for various applications, including thermal insulation in buildings, industrial equipment, and appliances.

- Q: Can fiberglass mat tissue be used for repairing fiberglass tanks?

- Yes, fiberglass mat tissue can be used for repairing fiberglass tanks. Fiberglass mat tissue is a thin, flexible material that is commonly used in the construction and repair of fiberglass products. It is designed to provide reinforcement and strength to the repaired areas. When applied with an appropriate resin, fiberglass mat tissue can effectively repair cracks, holes, or damaged sections of fiberglass tanks. However, it is important to ensure that the repair is done in a proper and professional manner, following the manufacturer's instructions and guidelines. Additionally, it is recommended to consult with an expert or specialist in fiberglass repair to ensure the best possible outcome for the repair.

- Q: Is fiberglass mat tissue suitable for insulation in industrial applications?

- Yes, fiberglass mat tissue is suitable for insulation in industrial applications. Fiberglass mat tissue is a lightweight and flexible material that offers excellent thermal insulation properties. It can effectively trap and retain heat, making it ideal for insulating industrial equipment and machinery. Additionally, it has good fire resistance properties, which is crucial in industrial settings where the risk of fire is higher. Fiberglass mat tissue is also resistant to corrosion, moisture, and chemicals, ensuring its durability and longevity in industrial applications. Overall, its thermal insulation capabilities, fire resistance, and resistance to various environmental factors make fiberglass mat tissue a suitable choice for insulation in industrial applications.

- Q: How does the thickness of fiberglass mat tissue affect its performance?

- The thickness of fiberglass mat tissue directly affects its performance. A thicker tissue provides increased strength, durability, and insulation properties. It also enhances the material's ability to absorb impact and resist damage. Thinner tissues, on the other hand, offer greater flexibility and easier handling. Therefore, choosing the appropriate thickness of fiberglass mat tissue is crucial to achieve desired performance characteristics in various applications.

- Q: What is the weight of fiberglass mat tissue per square meter?

- The weight of fiberglass mat tissue per square meter can vary depending on the specific product and manufacturer. Generally, fiberglass mat tissues can have a weight ranging from 100 grams per square meter (gsm) to 900 gsm. However, it is important to note that the weight can also be expressed in ounces per square yard (oz/yd²) in some cases. To determine the exact weight of a specific fiberglass mat tissue, it is best to refer to the product specifications provided by the manufacturer.

Send your message to us

Fiberglass Mat Tissue Glass Wool Insulation with Aluminum Foil Faced

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords