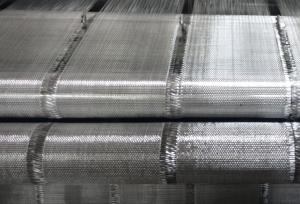

Fiberglass Mat Tissue for Pipe Coating Glass Fiber Felt

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Coated glass fiber mat is dedicated pipeline wet fiberglass mat coated for corrosion protection of buried steel is widely used in petroleum, natural gas pipeline anticorrosion coating.

Main features:

1, fibers uniformly dispersed

2, high strength, good flexibility

3, corrosion resistance, good flame retardant properties

4, anti-permeability good, strong resistance to environmental media capabilities

Technical specifications:

Product Code | Unit Weight(g/㎡) | Gum content(%) | Tendons from(mm) | Longitudinal tensile strength(N/5cm) | The transverse tensile strength(N/5cm) |

S-GD-50/T | 50 | 18 | 15,30 | ≥220 | ≥70 |

S-GD-60/T | 60 | 18 | 15,30 | ≥240 | ≥90 |

S-GD-90/T | 90 | 18 | 15,30 | ≥400 | ≥180 |

Packaging:

with cartons in pallets

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Can fiberglass mat tissue be used for repairing fiberglass structures?

- Fiberglass structures can be repaired using fiberglass mat tissue. This material is widely used in the construction and repair of fiberglass structures because of its versatility. Its purpose is to strengthen and reinforce damaged areas of the structure. To ensure a durable repair, the mat tissue is usually applied with resin, which bonds the fibers together. It is particularly effective for fixing cracks, holes, and other damages on fiberglass surfaces. In summary, fiberglass mat tissue is an outstanding option for repairing fiberglass structures due to its strength, flexibility, and ability to adapt to different shapes and sizes.

- Q: Is fiberglass mat tissue suitable for underground applications?

- Fiberglass mat tissue is perfect for use underground. This material is widely utilized in various industries like construction, infrastructure, and plumbing because of its exceptional strength, durability, and ability to resist environmental factors. Underground environments often present difficulties such as moisture, high humidity, and corrosive substances, which can compromise traditional materials. However, fiberglass mat tissue is specifically designed to endure these conditions, making it an excellent choice for underground applications. Moreover, its non-combustible nature and resistance to chemicals ensure it is a dependable option for areas where fire safety is a concern. In conclusion, fiberglass mat tissue is a versatile and reliable material that can effectively endure the challenges of underground environments.

- Q: What is the dimensional stability of fiberglass mat tissue?

- The dimensional stability of fiberglass mat tissue refers to its ability to maintain its shape and size even when exposed to changes in temperature, humidity, or mechanical stress. Due to its high strength and stiffness, fiberglass mat tissue is known for its excellent dimensional stability, making it suitable for various applications such as insulation, reinforcement, and composite materials.

- Q: Is fiberglass mat tissue suitable for aerospace interiors?

- Yes, fiberglass mat tissue is suitable for aerospace interiors. Fiberglass mat tissue is a lightweight and highly versatile material that offers excellent strength and durability. It is commonly used in aerospace applications due to its ability to meet stringent fire safety requirements, such as low smoke and toxicity emissions. Additionally, fiberglass mat tissue is resistant to moisture, chemicals, and temperature variations, making it an ideal choice for the demanding conditions inside an aircraft cabin. Its excellent sound insulation properties further enhance its suitability for aerospace interiors, ensuring a comfortable and quiet environment for passengers. Overall, fiberglass mat tissue offers a reliable and efficient solution for aerospace interior applications.

- Q: What is the moisture absorption rate of fiberglass mat tissue?

- The moisture absorption rate of fiberglass mat tissue is relatively low, as fiberglass is known for its water-resistant properties.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The adhesion of resin to fiberglass mat tissue can be significantly influenced by its surface finish. The surface finish pertains to the texture or smoothness of the fiberglass mat tissue. In general, a rough surface finish tends to promote better adhesion to resin. This is because a rough surface provides a larger area for the resin to adhere to, resulting in a stronger bond. Rough surface finishes can be achieved through different manufacturing techniques, such as using coarser fibers or incorporating texturizing agents during production. On the contrary, a smoother surface finish may lead to weaker adhesion. A smooth surface does not offer as much area for the resin to bond with, resulting in a weaker and less durable bond. Smoother surface finishes can be attained by using finer fibers or through additional processing steps to smoothen the surface. When selecting the surface finish of fiberglass mat tissue, it is crucial to consider the specific application and requirements. For applications that necessitate high strength and durability, a rougher surface finish may be preferable to ensure optimal adhesion to the resin. Conversely, for applications where a weaker bond is acceptable or where a smoother surface finish is desired for aesthetic reasons, a smoother surface finish may be chosen. Ultimately, the surface finish of fiberglass mat tissue plays a vital role in determining the adhesion to resin. It is essential to choose the appropriate surface finish to achieve the desired strength, durability, and performance in various applications.

- Q: Is fiberglass mat tissue suitable for construction applications?

- Indeed, fiberglass mat tissue proves to be a fitting material for construction purposes. Renowned for its robustness, longevity, and ability to withstand diverse environmental conditions, this versatile substance is frequently employed in roofing, flooring, insulation, and wall panel installations. Fiberglass mat tissue emerges as an exceptional selection for construction ventures as it bestows reinforcement and stability upon a range of materials. When incorporated into roofing materials, it fortifies them against impacts, weathering, and fires. Similarly, it bolsters the strength and durability of flooring systems, rendering them capable of withstanding substantial loads and heavy foot traffic. Moreover, fiberglass mat tissue exhibits commendable insulation capabilities. It serves as an efficacious insulating component for walls, ceilings, and floors, enabling the maintenance of a comfortable indoor temperature while diminishing energy consumption. Its thermal and acoustic insulation properties render it an ideal choice for construction applications. Furthermore, its imperviousness to moisture, chemicals, and corrosion makes fiberglass mat tissue a suitable option for deployment in areas characterized by high humidity or exposure to harsh chemicals. Thanks to its resistance to decay, it guarantees durability, ensuring longevity in construction projects. To conclude, fiberglass mat tissue is an apt choice for construction applications due to its strength, durability, insulation properties, and resistance to various environmental factors. Its adaptability and reliability have cemented its popularity within the construction industry.

- Q: What is the expected lifespan of fiberglass mat tissue in cryogenic applications?

- The expected lifespan of fiberglass mat tissue in cryogenic applications can vary depending on various factors such as the quality of the material, the specific cryogenic environment, and the maintenance and handling practices. Generally, fiberglass mat tissue is known for its excellent insulation properties and resistance to extreme temperatures. It is commonly used in cryogenic applications to provide thermal insulation and structural support. In well-maintained and controlled cryogenic environments, fiberglass mat tissue can have a lifespan of several decades. However, it is important to note that factors such as exposure to intense thermal cycling, mechanical stress, and chemical exposure can affect the performance and lifespan of the material. To ensure the longevity of fiberglass mat tissue in cryogenic applications, regular inspections, maintenance, and adherence to manufacturer's guidelines are crucial. It is also recommended to monitor and address any signs of degradation or damage promptly to prevent potential issues or failures.

- Q: How does the thickness of fiberglass mat tissue affect its performance?

- The thickness of fiberglass mat tissue plays a crucial role in determining its performance. Thicker fiberglass mat tissues generally provide better strength and durability compared to thinner ones. A thicker mat tissue allows for a higher resin-to-glass ratio, resulting in improved stiffness and toughness. This increased resin content enhances the overall structural integrity and mechanical properties of the fiberglass mat tissue. It also helps to minimize the risk of delamination and improves resistance to impact and fatigue. Moreover, thicker fiberglass mat tissues are more effective in providing thermal and acoustic insulation. The increased thickness allows for a higher density of fibers, which enhances the material's ability to trap air and reduce heat transfer or sound transmission. However, it is important to note that the specific application and requirements should be considered when determining the appropriate thickness of fiberglass mat tissue. While thicker tissues generally offer better performance, they may also be heavier and more expensive. Therefore, a balance must be struck between the desired performance characteristics and the practical considerations of weight, cost, and ease of installation.

- Q: What is the expected lifespan of fiberglass mat tissue in sports facility applications?

- The expected lifespan of fiberglass mat tissue in sports facility applications can vary depending on various factors such as the quality of the material, the level of maintenance and care, and the specific conditions in which it is used. However, generally speaking, fiberglass mat tissue has a relatively long lifespan and is known for its durability. When properly installed and maintained, fiberglass mat tissue can last for several decades. It is resistant to corrosion, rot, and degradation, making it suitable for use in sports facilities where it may be exposed to moisture, humidity, and other environmental factors. To maximize the lifespan of fiberglass mat tissue in sports facility applications, regular inspections, cleanings, and repairs may be necessary. It is also important to follow manufacturer recommendations for installation and maintenance to ensure optimal performance and longevity. It is worth noting that while fiberglass mat tissue is known for its durability, it may still experience wear and tear over time, especially in high-impact areas or in facilities with heavy usage. In such cases, periodic replacements or repairs may be required to maintain the integrity and functionality of the material. Overall, fiberglass mat tissue is a reliable and long-lasting option for sports facility applications, and with proper care and maintenance, it can provide excellent performance and durability for many years.

Send your message to us

Fiberglass Mat Tissue for Pipe Coating Glass Fiber Felt

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords