Fiberglass Mat Tissue - Fiberglass Woven Roving Combo Mat 1250g 200~2600mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

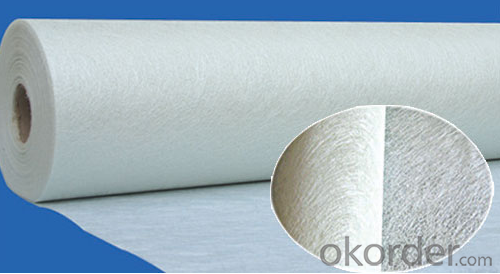

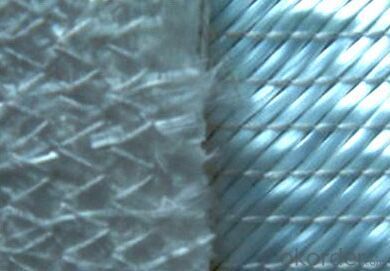

Structure of woven roving combo mat Description:

◎ This mat is a combination of woven roving and chopped glass fiber. The layer of chopped strand is stitched together with woven roving by polyester thread. It is mainly applied in the processes of molding compressing, pultrusion, RTM, filament winding etc..

◎ This fabric is compatible with UP Resin, Vinyl ester resin, epoxy resin system etc. It is widely used in vehicle bodies and panels, marine (boat hulls and decks), pipeline, lamination and structural profiles

Main Features of the woven roving combo mat

◎ Increase strength, reduce product weight and better surface finish.

◎ low resin-consumption and faster wet-out.

◎ Good manufacturability and mechanical properties

◎ Improved fatigue and impact resistance

Woven roving combo mat Images

Woven roving combo mat Specification:

| ||||||||||||||||||||||||||||||||||||||||

FAQ of Woven roving combo mat:

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: pultrusion, RTM, hand lay up, etc.

• Ultimate products: pultruded profiles, FRP body of boat, insulation board, automobile body.

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: Are there any environmental considerations when using fiberglass mat tissue?

- Yes, there are several environmental considerations when using fiberglass mat tissue. Firstly, the production of fiberglass mat tissue involves the use of energy and resources. The manufacturing process requires the extraction of raw materials, such as silica sand, limestone, and soda ash, which are non-renewable resources. The energy-intensive process of melting these materials at high temperatures also contributes to greenhouse gas emissions. Additionally, the production of fiberglass involves the use of chemicals, such as resins and binders, which can be harmful to the environment if not properly managed. These chemicals can potentially leach into water bodies or soil if not handled and disposed of correctly. Furthermore, fiberglass mat tissue is not biodegradable. Once it reaches the end of its lifespan, it can take hundreds of years to break down in a landfill. Improper disposal of fiberglass mat tissue can lead to environmental pollution and contribute to the growing problem of waste management. Lastly, the use of fiberglass mat tissue in certain applications, such as insulation or construction, can have energy efficiency implications. While fiberglass is an effective insulator, its production and installation may require additional energy inputs, such as the use of fossil fuels for transportation or heating during installation. To mitigate these environmental considerations, it is important to promote sustainable practices in the production and use of fiberglass mat tissue. This can include implementing energy-efficient manufacturing processes, reducing the use of harmful chemicals, promoting recycling or reuse of fiberglass materials, and exploring alternative materials that have a lower environmental impact.

- Q: How is fiberglass mat tissue used in the production of sports equipment?

- Fiberglass mat tissue is used in the production of sports equipment as it provides strength, flexibility, and durability to the final product. It is commonly used as a reinforcement material in the manufacturing of sports equipment such as snowboards, surfboards, hockey sticks, and tennis rackets. The fiberglass mat tissue is typically layered with resin and other materials, forming a composite structure that enhances the overall performance and longevity of the sports equipment.

- Q: Does anyone know the hardness value of the heat conductive gasket? Does it contain the hardness of the carrier (glass fiber)?

- The purpose of glass fiber is to make the product more convenient for processing, containing a layer of glass fiber cloth, then the operation process is not easy to damage thermal conductive gasket

- Q: How does fiberglass mat tissue perform in terms of mold and mildew resistance?

- Fiberglass mat tissue possesses exceptional mold and mildew resistance. Its inherent moisture resistance prevents the proliferation of mold and mildew. Moreover, fiberglass is impermeable and unsuitable for the flourishing of these microorganisms. Furthermore, fiberglass mat tissue finds extensive usage in areas with high humidity, like bathroom walls or showers, and has proven highly efficient in deterring mold and mildew growth. All in all, fiberglass mat tissue exhibits outstanding performance in terms of mold and mildew resistance, rendering it a dependable option for situations where these issues are prominent.

- Q: Is fiberglass mat tissue suitable for agricultural applications?

- Certainly! Fiberglass mat tissue proves to be a suitable option for agricultural uses. Its versatility makes it an ideal material in the agricultural sector, providing numerous advantages. The resistance of fiberglass mat tissue to moisture, chemicals, and UV radiation makes it perfect for applications like greenhouse roofing, animal enclosures, and agricultural equipment. It possesses exceptional insulation properties, aiding in the regulation of temperature and safeguarding crops or livestock against harsh weather conditions. Moreover, fiberglass mat tissue is lightweight, easy to install, and long-lasting, making it an economical choice for agricultural projects. In conclusion, fiberglass mat tissue is a fitting material for a wide range of agricultural applications, ensuring durability, flexibility, and safeguarding for the farming industry.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The adhesion of resin to fiberglass mat tissue can be significantly influenced by its surface finish. The surface finish pertains to the texture or smoothness of the fiberglass mat tissue. In general, a rough surface finish tends to promote better adhesion to resin. This is because a rough surface provides a larger area for the resin to adhere to, resulting in a stronger bond. Rough surface finishes can be achieved through different manufacturing techniques, such as using coarser fibers or incorporating texturizing agents during production. On the contrary, a smoother surface finish may lead to weaker adhesion. A smooth surface does not offer as much area for the resin to bond with, resulting in a weaker and less durable bond. Smoother surface finishes can be attained by using finer fibers or through additional processing steps to smoothen the surface. When selecting the surface finish of fiberglass mat tissue, it is crucial to consider the specific application and requirements. For applications that necessitate high strength and durability, a rougher surface finish may be preferable to ensure optimal adhesion to the resin. Conversely, for applications where a weaker bond is acceptable or where a smoother surface finish is desired for aesthetic reasons, a smoother surface finish may be chosen. Ultimately, the surface finish of fiberglass mat tissue plays a vital role in determining the adhesion to resin. It is essential to choose the appropriate surface finish to achieve the desired strength, durability, and performance in various applications.

- Q: How does fiberglass mat tissue compare to other reinforcing materials, such as carbon fiber or kevlar?

- Fiberglass mat tissue, carbon fiber, and Kevlar are all reinforcing materials commonly used in various industries for their high strength and durability. However, they differ in their composition and properties, leading to different applications and performance characteristics. Fiberglass mat tissue is made from fine glass fibers randomly oriented and bonded together with a binder. It offers excellent tensile strength, corrosion resistance, and low cost, making it widely used in construction, automotive, and marine industries. Fiberglass mat tissue is also highly flexible, allowing it to conform to complex shapes easily. However, it may not have the same strength-to-weight ratio as carbon fiber or Kevlar. Carbon fiber is composed of thin strands of carbon atoms tightly woven together, resulting in an extremely strong and lightweight material. It has a higher tensile strength than fiberglass mat tissue, making it suitable for applications where weight reduction and high strength are critical, such as aerospace, sports equipment, and automotive components. Carbon fiber also has excellent stiffness and fatigue resistance, but it is more expensive compared to fiberglass mat tissue. Kevlar, on the other hand, is an aramid fiber known for its exceptional strength-to-weight ratio and resistance to impact and abrasion. It is often used in applications where high impact resistance is required, such as bulletproof vests, helmets, and protective clothing. While Kevlar is stronger than fiberglass mat tissue, it is not as rigid as carbon fiber and may not offer the same level of stiffness. Kevlar is also more expensive than fiberglass mat tissue but less expensive than carbon fiber. In summary, fiberglass mat tissue, carbon fiber, and Kevlar each have their own unique characteristics and advantages. Fiberglass mat tissue is versatile, cost-effective, and flexible, while carbon fiber offers exceptional strength and stiffness. Kevlar excels in impact resistance and durability. The choice of reinforcing material depends on the specific application requirements, cost considerations, and desired performance characteristics.

- Q: Can fiberglass mat tissue be used for reinforcing pipes?

- Yes, fiberglass mat tissue can be used for reinforcing pipes. It provides strength and durability to the pipe structure, making it resistant to cracks and leaks.

- Q: Can fiberglass mat tissue be used for insulation?

- Yes, fiberglass mat tissue can be used for insulation. It is commonly used in various applications such as thermal insulation for buildings, pipes, and equipment. The fiberglass mat tissue helps to trap air and reduce heat transfer, making it an effective option for insulation purposes.

- Q: What is the shear strength of fiberglass mat tissue?

- The shear strength of fiberglass mat tissue can vary depending on various factors such as the specific type of fiberglass mat tissue, its thickness, and the manufacturing process. However, in general, fiberglass mat tissue typically has a relatively high shear strength due to the inherent strength and rigidity of fiberglass materials.

Send your message to us

Fiberglass Mat Tissue - Fiberglass Woven Roving Combo Mat 1250g 200~2600mm

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords