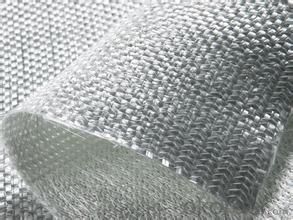

Fiberglass Mat Tissue - E-Glass Fiber Woven Roving Fabric for GRP Usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description Of Products

E-Glass Woven Rovings are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

E-Glass Woven Rovings are a high-performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

Good moldability, fast and complete wet out in resins, resulting in high productivity

Good mechanical properties and high strength of parts

Product Specifications

Property | Area Weight | Moisture Content | Size Content | Width |

(%) | (%) | (%) | (mm) | |

Test Method | IS03374 | ISO3344 | ISO1887 | |

EWR200 | ±7.5 | ≤0.15 | 0.4-0.8 | 20-3000 |

EWR270 | ||||

EWR300 | ||||

EWR360 | ||||

EWR400 | ||||

EWR500 | ||||

EWR600 | ||||

EWR800 |

FAQ

Each woven roving is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 220mm. The woven roving roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Unless otherwise specified,It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Is fiberglass mat tissue suitable for wind energy applications?

- Indeed, fiberglass mat tissue proves to be a fitting choice for wind energy applications. This lightweight and resilient material is often employed in the fabrication of wind turbine blades. It possesses remarkable strength and rigidity, rendering it well-suited to endure the formidable strains and pressures exerted on wind turbines. Furthermore, fiberglass mat tissue exhibits resistance against corrosion and deterioration caused by UV radiation, thereby guaranteeing the durability and functionality of wind turbine blades. In summary, the integration of fiberglass mat tissue into wind energy applications enables the creation of efficient and dependable wind turbines capable of generating clean and sustainable energy.

- Q: Is fiberglass mat tissue easy to install?

- Installing fiberglass mat tissue is relatively easy. This lightweight and flexible material can be easily cut and shaped to fit any surface. It can be applied using different methods, including spraying, rolling, or brushing on adhesive. Moreover, the tissue is self-adhesive, which simplifies the installation process as it readily adheres to the desired surface. Additionally, fiberglass mat tissues are generally designed to resist water and offer excellent insulation, making them a favored choice for various applications. In conclusion, by adequately preparing and following the manufacturer's guidelines, installing fiberglass mat tissue can be a simple and trouble-free task.

- Q: Can fiberglass mat tissue be used for acoustic insulation?

- Indeed, acoustic insulation can be achieved by utilizing fiberglass mat tissue. This lightweight material possesses remarkable sound absorption qualities, allowing it to proficiently absorb and diminish sound waves, thereby reducing noise levels and enhancing the acoustic atmosphere. In the realm of construction, fiberglass mat tissue is widely employed to insulate walls, ceilings, and floors in order to minimize noise propagation. Moreover, it finds application in the automotive sector and various other industries that demand sound insulation. With its exceptional porosity and fibrous composition, fiberglass mat tissue proves to be an optimal substance for sound wave absorption and attenuation, rendering it highly suitable for acoustic insulation purposes.

- Q: Does fiberglass mat tissue require any special handling precautions?

- Yes, fiberglass mat tissue does require special handling precautions. It is important to wear appropriate protective gear such as gloves, goggles, and a respirator when working with fiberglass mat tissue to prevent skin, eye, and respiratory irritation. Additionally, it is recommended to work in a well-ventilated area to minimize exposure to fiberglass particles.

- Q: What are the advantages of using fiberglass mat tissue?

- There are several advantages to using fiberglass mat tissue in various applications. Firstly, fiberglass mat tissue is lightweight, making it easy to handle and transport. This makes it a practical choice for construction and manufacturing industries. Secondly, fiberglass mat tissue offers excellent strength and durability. It has a high tensile strength, which means it can withstand heavy loads and resist tearing or breaking. This makes it an ideal material for reinforcing structures and providing structural integrity. Additionally, fiberglass mat tissue is highly resistant to corrosion, chemicals, and weathering. It does not rust, rot, or degrade when exposed to harsh environmental conditions, making it suitable for outdoor applications. Another advantage of using fiberglass mat tissue is its versatility. It can be easily molded into different shapes and sizes, making it suitable for a wide range of applications. Whether it's used for building materials, automotive parts, or even boat hulls, fiberglass mat tissue can be tailored to meet specific design requirements. Furthermore, fiberglass mat tissue is an excellent thermal insulator. It can effectively trap heat, making it energy-efficient and cost-effective for insulation purposes. This can contribute to reducing energy consumption and lowering heating or cooling costs in buildings. Lastly, fiberglass mat tissue is fire-resistant. It does not ignite easily and can withstand high temperatures without melting or releasing toxic fumes. This makes it a safe choice for applications where fire safety is a concern, such as in the construction of fire-resistant doors or insulation materials. In summary, the advantages of using fiberglass mat tissue include its lightweight nature, strength and durability, resistance to corrosion and weathering, versatility in design, thermal insulation properties, and fire resistance. These qualities make it a highly desirable material in various industries and applications.

- Q: Does anyone know the hardness value of the heat conductive gasket? Does it contain the hardness of the carrier (glass fiber)?

- The hardness of the heat conducting gasket does not contain the hardness of the carrier glass fiber.

- Q: How does fiberglass mat tissue perform in terms of thermal expansion?

- Fiberglass mat tissue has a relatively low thermal expansion coefficient, meaning it expands minimally when exposed to heat. This characteristic makes it an excellent material for applications where thermal stability is crucial. The tightly woven structure of fiberglass mat tissue helps to limit the expansion and contraction of the material, even under high temperatures. Consequently, it exhibits excellent dimensional stability and resistance to thermal stresses. This property allows fiberglass mat tissue to maintain its structural integrity when exposed to extreme temperature variations, making it highly suitable for use in industries such as aerospace, automotive, and construction, where thermal expansion and contraction can pose significant challenges.

- Q: Is fiberglass mat tissue suitable for oil and gas applications?

- Indeed, fiberglass mat tissue proves to be fitting for oil and gas applications. This material, renowned for its lightweight yet robust nature, demonstrates resilience in the face of the demanding conditions that typically arise within the oil and gas sector. Its extraordinary resistance to chemicals, including oil and gas, renders it an optimal selection for endeavors like pipeline insulation, tank lining, and filtration systems. Moreover, fiberglass mat tissue showcases exceptional resistance to moisture absorption, possesses commendable thermal insulation characteristics, and can be effortlessly molded into diverse shapes and forms, thereby establishing itself as a versatile substance suitable for a wide range of oil and gas applications.

- Q: How does fiberglass mat tissue perform in terms of dimensional stability?

- The dimensional stability of fiberglass mat tissue is exceptional. This is due to its unique composition and manufacturing process, which result in minimal shrinkage or expansion when exposed to temperature variations or moisture. As a result, fiberglass mat tissue is an ideal material for various applications in the construction industry, where dimensional stability is crucial. It is commonly used to reinforce walls, roofs, and floors. The consistent size and shape of fiberglass mat tissue ensure that it maintains its original dimensions over time, providing long-lasting durability and reliability. Furthermore, its dimensional stability allows for precise cutting, shaping, and installation, reducing waste and increasing efficiency in manufacturing processes. Overall, the excellent dimensional stability of fiberglass mat tissue makes it a preferred choice in industries where accurate and stable dimensions are essential.

- Q: How does the fiber orientation of fiberglass mat tissue affect its strength?

- The fiber orientation of fiberglass mat tissue greatly affects its strength. When the fibers are aligned in a specific direction, they provide maximum strength in that direction. However, if the fibers are randomly oriented, the overall strength of the material is reduced as the load may not be evenly distributed among the fibers. Therefore, proper fiber orientation is crucial in maximizing the strength of fiberglass mat tissue.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiber Woven Roving Fabric for GRP Usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords