Glass Wool Insulation Blanket With Aluminum Foil Facing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

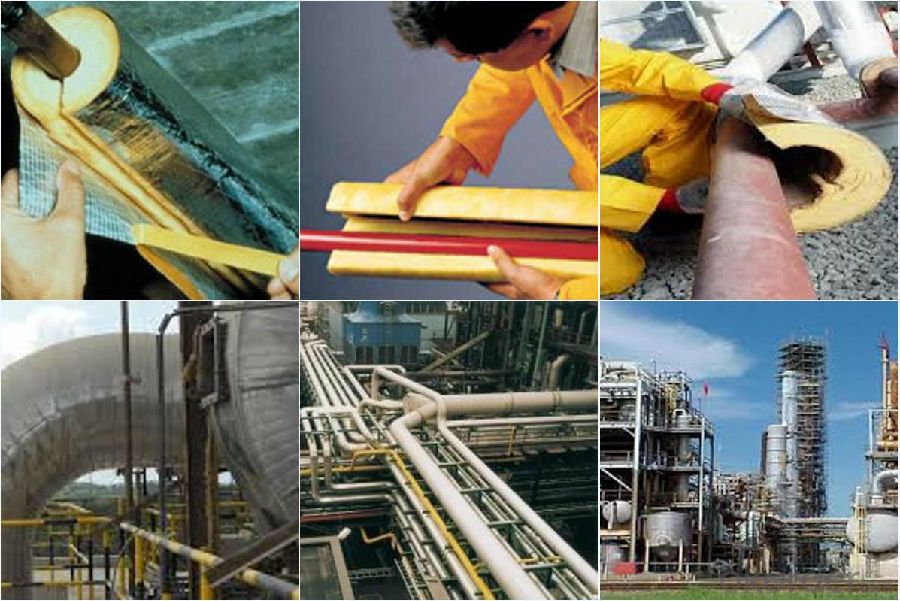

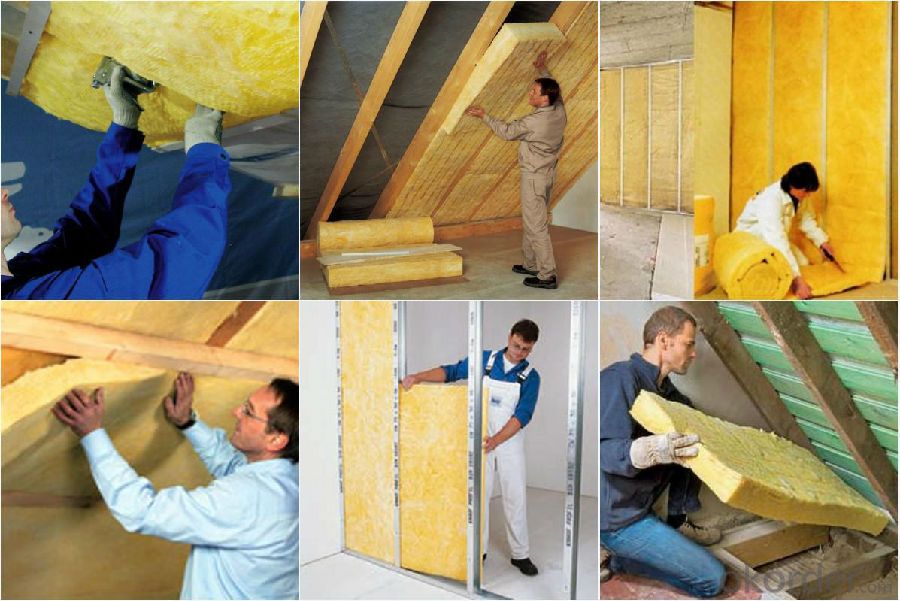

Glass Wool Blanket complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Excellent thermal, acoustical properties

2.Light weight and easy to fabricate on job site

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can fiberglass mat tissue be used as a reinforcement in concrete?

- Yes, fiberglass mat tissue can be used as a reinforcement in concrete. Fiberglass mat tissue is a thin, lightweight material made from woven fiberglass strands. It is commonly used in construction and industrial applications due to its high strength and durability. When used as reinforcement in concrete, fiberglass mat tissue can help to increase the tensile strength and crack resistance of the concrete. It is typically applied in the form of a mesh or fabric, which is embedded within the concrete during the pouring process. The fiberglass strands in the mat tissue provide additional strength and reinforcement to the concrete, helping to prevent cracking and improve overall structural integrity. This can be particularly beneficial in areas where the concrete is subject to high loads, such as in bridges, concrete slabs, or precast concrete elements. Furthermore, fiberglass mat tissue is corrosion-resistant, which makes it a suitable choice for applications where the concrete is exposed to moisture or chemicals. It does not rust or degrade over time, unlike traditional steel reinforcement, which can help to extend the lifespan of the concrete structure. Overall, fiberglass mat tissue is a viable and effective reinforcement option for concrete. It offers enhanced strength, crack resistance, and corrosion resistance, making it a popular choice in various construction projects.

- Q: Is fiberglass mat tissue resistant to moisture?

- Fiberglass mat tissue, indeed, exhibits resistance to moisture. By tightly weaving strands of glass fibers and subsequently bonding them with a resin, this tissue fabricates a barrier that effectively thwarts the infiltration of moisture. Consequently, the moisture-resistant properties of fiberglass mat tissue render it exceptionally suitable for deployment in scenarios where water exposure or high humidity is anticipated. Moreover, this tissue's resistance to moisture aids in averting the proliferation of mold or mildew, thereby establishing it as an appropriate selection for environments prone to dampness.

- Q: Does fiberglass mat tissue require any special maintenance after installation?

- No, fiberglass mat tissue does not require any special maintenance after installation.

- Q: What are the main applications of fiberglass mat tissue?

- The main applications of fiberglass mat tissue include reinforcement in the construction industry for roofing, walls, and flooring, as well as insulation in thermal and acoustic systems. It is also used in the manufacturing of automotive parts, boats, and pipes for their strength and durability. Additionally, it finds use in the production of printed circuit boards and as a filtration medium in air and liquid filtration systems.

- Q: Is fiberglass mat tissue resistant to moisture vapor transmission?

- Indeed, fiberglass mat tissue exhibits resistance to the transmission of moisture vapor. It serves as a remarkably robust and moisture-resistant substance, frequently employed in a multitude of scenarios that prioritize moisture management, including roofing, insulation, and flooring. The design of the fiberglass mat tissue is specifically tailored to impede the passage of moisture vapor, thereby preserving the quality and functionality of the accompanying materials. Given its capacity to resist the transmission of moisture vapor, the fiberglass mat tissue emerges as an optimal selection for environments where moisture control is of utmost importance.

- Q: Can fiberglass mat tissue be used for electrical enclosures?

- No, fiberglass mat tissue is not suitable for electrical enclosures as it does not provide sufficient insulation properties necessary for electrical safety.

- Q: Can fiberglass mat tissue be used for decorative applications?

- Yes, fiberglass mat tissue can be used for decorative applications. Its versatility and ability to be molded into various shapes make it suitable for creating decorative elements such as wall panels, sculptures, and other artistic installations. Additionally, its lightweight nature, durability, and resistance to corrosion make it an ideal choice for both indoor and outdoor decorative applications.

- Q: Can fiberglass mat tissue be used for ballistic protection?

- No, fiberglass mat tissue cannot be used for ballistic protection. It is not designed or tested to withstand the high-velocity impact of bullets or projectiles. Ballistic protection requires specialized materials such as Kevlar, aramid fibers, or ceramic plates that are specifically engineered to provide adequate protection against ballistic threats.

- Q: Can fiberglass mat tissue be used for insulation in power generation facilities?

- Yes, fiberglass mat tissue can be used for insulation in power generation facilities. Fiberglass mat tissue is a versatile material that is commonly used for insulation purposes due to its excellent thermal and electrical insulation properties. It is resistant to high temperatures and can effectively trap and prevent the transfer of heat, making it suitable for use in power generation facilities where heat management is crucial. Additionally, fiberglass mat tissue is lightweight, easy to install, and offers high durability and longevity, making it a cost-effective choice for insulation in power generation facilities.

- Q: Can fiberglass mat tissue be used for thermal insulation?

- No, fiberglass mat tissue is not typically used for thermal insulation. It is primarily used for reinforcing and providing strength to composite materials such as fiberglass sheets or panels. For thermal insulation purposes, other materials such as mineral wool, foam, or cellulose insulation are commonly used.

Send your message to us

Glass Wool Insulation Blanket With Aluminum Foil Facing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords