Fiberglass Mat Tissue Woven Roving Combo Mat 980gsm, 1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Process

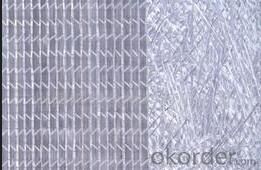

Fiberglass stitch combo mat is the mat combining the woven roving and a even layer of chopped strand mat with polyester yarn.

Properties

• Fiber level unfolded without cross, high density, high utilizing rate.

• Multi-layer finished one time, decrease layer and enhance efficiency.

• Providing the product with multi-directional mechanical strength.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: pultrusion, RTM, hand lay up, etc.

• Ultimate products: pultruded profiles, FRP body of boat, insulation board, automobile body.

Specifications

specifications | Fibre type | Wover roving | Chopped strand | Overall weight | Width |

(g/㎡) | (g/㎡) | (g/㎡) | (mm) | ||

EMK 600/300 | E-Glass | 600 | 300 | 900 | 1600/2400 |

EMK 600/380 | E-Glass | 600 | 380 | 980 | 1600/2400 |

EMK 600/450 | E-Glass | 600 | 450 | 1050 | 1600/2400 |

EMK 800/300 | E-Glass | 800 | 300 | 1100 | 1600/2400 |

EMK 800/380 | E-Glass | 800 | 380 | 1180 | 1600/2400 |

EMK 800/450 | E-Glass | 800 | 450 | 1250 | 1600/2400 |

Packaging: Wrapped in PVC and placed within a cardboard carton. | |||||

- Q: What is the cost of fiberglass mat tissue?

- The price of fiberglass mat tissue can fluctuate based on a variety of factors including the brand, quality, quantity, and location. Typically, the cost per square foot for fiberglass mat tissue falls between $0.50 and $2. However, it is crucial to consider that prices may vary depending on the project's specific requirements and the supplier or retailer from whom it is obtained. To ensure the best value and appropriateness for your needs, it is advisable to conduct thorough research and compare prices from different sources.

- Q: Can fiberglass mat tissue be used for HVAC ducting?

- Yes, fiberglass mat tissue can be used for HVAC ducting.

- Q: Can fiberglass mat tissue be used for marine applications?

- Fiberglass mat tissue finds widespread use in marine applications. It serves multiple purposes in the marine industry, including boat construction, repairs, and maintenance. This material boasts remarkable strength, durability, and water resistance, rendering it an optimal choice for marine applications. Additionally, fiberglass mat tissue is lightweight and malleable, enabling convenient shaping and customization. It remains impervious to corrosion caused by saltwater and other harsh marine conditions. Consequently, fiberglass mat tissue emerges as a dependable and adaptable material that enjoys frequent employment within the marine industry.

- Q: Does fiberglass mat tissue require any special precautions during transportation?

- Yes, fiberglass mat tissue does require special precautions during transportation. Fiberglass mat tissue is a delicate material that can easily get damaged if not handled properly. Therefore, it is important to take certain precautions to ensure its safe transportation. Firstly, the fiberglass mat tissue should be packed in a sturdy and durable packaging material that can protect it from any external impacts or vibrations. This can be achieved by using heavy-duty cardboard boxes or wooden crates that provide adequate cushioning and support. Additionally, it is crucial to label the packaging clearly as "Fragile" or "Handle with Care" to alert the handlers about the delicate nature of the product. This will help prevent any mishandling or rough treatment during transportation. Furthermore, fiberglass mat tissue should be stored and transported in an upright position to minimize the risk of any bending or folding that could potentially damage the material. It is also important to avoid stacking heavy objects on top of the fiberglass mat tissue to prevent any unnecessary pressure or crushing. Lastly, it is advisable to use secure and reliable transportation services that have experience in handling delicate materials like fiberglass mat tissue. This ensures that the product is transported with utmost care and attention, reducing the chances of any damage during transit. By following these special precautions, the risk of damage to the fiberglass mat tissue during transportation can be significantly minimized, ensuring that it reaches its destination in perfect condition.

- Q: How is fiberglass mat tissue used in the production of water tanks?

- Fiberglass mat tissue, a type of non-woven fabric made from glass fibers, is commonly used in the production of water tanks due to its excellent strength, durability, and resistance to corrosion. Water tanks are typically made from fiberglass reinforced plastic (FRP), which is a composite material consisting of a polymer matrix reinforced with fiberglass. The fiberglass mat tissue plays a crucial role in this process as it serves as the reinforcement material. Firstly, the fiberglass mat tissue is cut into the desired shape and size to fit the mold of the water tank. It is then layered onto the mold, with the number of layers depending on the required strength and thickness of the tank. Once the fiberglass mat tissue is in place, a resin matrix is applied to impregnate and bind the fibers together. This resin can be polyester, vinyl ester, or epoxy, depending on the specific requirements of the water tank. The resin is typically applied using a spray or a roller, ensuring that it thoroughly saturates the fiberglass mat tissue. This process is often repeated multiple times to build up the necessary thickness and strength of the tank. After the resin has cured, the fiberglass mat tissue and resin composite becomes rigid and forms the structure of the water tank. The resulting FRP tank is lightweight, yet incredibly strong and durable, making it an ideal choice for storing and transporting water. The use of fiberglass mat tissue in water tank production provides several advantages. Firstly, it enhances the structural integrity of the tank, allowing it to withstand external forces such as pressure and impact. Secondly, fiberglass is highly resistant to corrosion, ensuring that the tank remains in good condition even when exposed to harsh environmental conditions or corrosive substances present in the water. Overall, fiberglass mat tissue is a critical component in the production of water tanks, providing strength, durability, and corrosion resistance, making it a reliable choice for various industrial, commercial, and residential applications.

- Q: Does fiberglass mat tissue provide any thermal insulation?

- Yes, fiberglass mat tissue does provide thermal insulation.

- Q: What are the different surface textures available for fiberglass mat tissue?

- There are several different surface textures available for fiberglass mat tissue. One common texture is a smooth surface, which is often used for applications that require a sleek and polished finish. This texture is achieved by using a smooth roller or mold during the manufacturing process, resulting in a flat and even surface. Another texture option is a coarse or rough surface, which is suitable for applications that require enhanced adhesion. This texture is achieved by using a textured roller or mold during manufacturing, creating a surface with small bumps or ridges that provide increased surface area for better bonding with adhesives or coatings. A third texture option is a patterned or embossed surface, which is used for applications that require aesthetic appeal or enhanced grip. This texture is achieved by using a patterned roller or mold during manufacturing, resulting in a surface with raised or recessed designs that can be visually appealing or provide added traction when used on flooring or decking materials. Additionally, manufacturers can customize the surface texture of fiberglass mat tissue to meet specific requirements. This can include creating a textured surface with specific patterns or designs to suit individual needs or preferences. Overall, the different surface textures available for fiberglass mat tissue allow for a wide range of applications, providing options for smooth finishes, enhanced adhesion, aesthetic appeal, or improved grip.

- Q: Is fiberglass mat tissue suitable for sound absorption?

- Yes, fiberglass mat tissue is suitable for sound absorption. Fiberglass has excellent acoustic properties, making it an effective material for reducing noise levels and improving sound quality in various applications. The fibrous structure of the mat tissue provides a high surface area to absorb sound waves, converting them into heat energy. This makes it an ideal material for soundproofing walls, ceilings, and floors in buildings, as well as for use in automotive, industrial, and marine applications. Additionally, fiberglass mat tissue is lightweight, easy to install, and has good durability and fire resistance, further enhancing its suitability for sound absorption purposes.

- Q: How does the thickness of fiberglass mat tissue affect its performance?

- The thickness of fiberglass mat tissue plays a crucial role in determining its performance. Thicker fiberglass mat tissues generally provide better strength and durability compared to thinner ones. A thicker mat tissue allows for a higher resin-to-glass ratio, resulting in improved stiffness and toughness. This increased resin content enhances the overall structural integrity and mechanical properties of the fiberglass mat tissue. It also helps to minimize the risk of delamination and improves resistance to impact and fatigue. Moreover, thicker fiberglass mat tissues are more effective in providing thermal and acoustic insulation. The increased thickness allows for a higher density of fibers, which enhances the material's ability to trap air and reduce heat transfer or sound transmission. However, it is important to note that the specific application and requirements should be considered when determining the appropriate thickness of fiberglass mat tissue. While thicker tissues generally offer better performance, they may also be heavier and more expensive. Therefore, a balance must be struck between the desired performance characteristics and the practical considerations of weight, cost, and ease of installation.

- Q: Is fiberglass mat tissue suitable for automotive applications?

- Yes, fiberglass mat tissue is suitable for automotive applications. It is commonly used for reinforcing and strengthening automotive parts such as body panels, hoods, and bumpers. The fiberglass mat tissue provides excellent strength, impact resistance, and durability, making it a reliable choice for automotive use.

Send your message to us

Fiberglass Mat Tissue Woven Roving Combo Mat 980gsm, 1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords