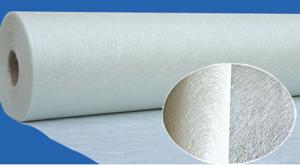

Fiberglass Mat Tissue Woven Roving Combo Mat 1100g(300/500/300)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description | |||||||||||||||||||||||||||||||||||||||

◎ This mat is a combination of woven roving and chopped glass fiber. The layer of chopped strand is stitched together with woven roving by polyester thread. It is mainly applied in the processes of molding compressing, pultrusion, RTM, filament winding etc.. ◎ Fiberglass combo mat is used the fiberglass roving weaved to enhanced fabric, suitable for all kinds of resin system. Woven roving is a high performance reinforced material, widely used in hand lay-up and mechanical molding products, such as boats, vessels, planes and automotive parts, furniture, sports facilities and other wide range of applications.

| |||||||||||||||||||||||||||||||||||||||

Product Traits | |||||||||||||||||||||||||||||||||||||||

◎ Increase strength, reduce product weight and better surface finish. ◎ Low thermal shrinkage | |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||

Service Advantages | |||||||||||||||||||||||||||||||||||||||

Quality guarantee for fiberglassneedle mat Reasonable price and best services. Flexible delivery for sample and big order. Many years of trading experience in this fiberglass needle mat

| |||||||||||||||||||||||||||||||||||||||

FAQ

1) which kind of glass fiber sample and materials can you provide?

We can provide the glass fiber and glass fiber down stream products samples of E glass, C glass, ECR glass, High alkali glass. The products include single end roving, assembled roving for different applications( Piping, SMC, panel, winding mill plate) , chop strand for BMC, engineering plastic (PA, PPA, PPT, POM, etc), chop strand mat (from 100gsm-900gsm) for automobile and water tank, etc, woven roving (270gsm-800gsm), surface tissue (25-50gsm), multi-axial fabric of different unit weight.

2) Can you provide glass fiber composite material?

We can provide GFRP profile such as grating, T beam, U beam and other assembles pieces such as GFRP triangle frame, dust bin, fireplace, etc

3) How much sample can you provide and who will bear the sample cost?

We can provide the glass fiber samples not more than 1kg free of change. However, the courier cost must be born by the customer. As to the glass fiber composite materials, we can provide the piece not more than 1kg free of change ( with the existing module). However, the courier cost must be born by the customer. If we need to make a new model, this excludes.

- Q: Can fiberglass mat tissue be used for windbreak panels?

- Yes, fiberglass mat tissue can be used for windbreak panels. It is a lightweight and durable material that can provide effective protection against wind and other environmental elements.

- Q: Is fiberglass mat tissue suitable for underground applications?

- Yes, fiberglass mat tissue is suitable for underground applications. It is commonly used in underground construction projects due to its excellent strength, durability, and resistance to water and corrosion. Additionally, fiberglass mat tissue provides insulation and reinforcement, making it ideal for underground applications such as tunnels, basements, and pipelines.

- Q: How does fiberglass mat tissue perform in terms of UV resistance?

- The UV resistance of fiberglass mat tissue is generally good. UV resistance refers to a material's ability to endure the harmful consequences of ultraviolet radiation without deteriorating. Fiberglass mat tissue is typically made by combining fiberglass and a binder material, which gives it strength and integrity. The fiberglass in the mat tissue inherently possesses UV resistance. Fiberglass is recognized for its durability and its capability to resist deterioration caused by UV exposure. It is a non-absorbent material that does not soak up UV radiation, making it less prone to damage from the sun's rays. Moreover, certain manufacturers may apply a UV-resistant coating or treatment to enhance the UV resistance of the fiberglass mat tissue. This additional coating or treatment offers extra protection against the harmful effects of extended UV radiation exposure. In general, fiberglass mat tissue performs admirably when it comes to UV resistance. It is a sturdy material that can endure the harmful consequences of UV radiation, making it suitable for situations where prolonged exposure to sunlight is anticipated. However, it is important to note that the specific UV resistance of fiberglass mat tissue can vary depending on factors such as the manufacturing process, the quality of materials used, and any additional coatings or treatments applied.

- Q: Is fiberglass mat tissue resistant to fading?

- Yes, fiberglass mat tissue is resistant to fading.

- Q: What are the different weights available for fiberglass mat tissue?

- The different weights available for fiberglass mat tissue range from 20 grams per square meter (gsm) to 100 gsm.

- Q: How is fiberglass mat tissue used in the production of storage sheds?

- Fiberglass mat tissue is used in the production of storage sheds to reinforce the structure and provide added strength and durability. It is typically applied as a layer in the construction process, serving as a reinforcement material for the shed's walls, roof, and floor. The fiberglass mat tissue helps to prevent cracking, increase resistance to weather elements, and improve overall longevity of the storage shed.

- Q: How is fiberglass mat tissue used in the production of storage containers?

- The unique properties and benefits of fiberglass mat tissue make it a common choice in the production of storage containers. This thin layer of non-woven glass fibers offers excellent strength and durability, reinforcing the structure of the containers and ensuring they can withstand heavy loads without deforming. In addition to its strength, fiberglass mat tissue is highly resistant to corrosion, moisture, and chemicals. This makes it perfect for storage containers that may be exposed to harsh environments or contain corrosive substances. By acting as a protective barrier, the fiberglass mat tissue prevents any potential damage or degradation to the container. Furthermore, fiberglass mat tissue is lightweight, making it easier and more cost-effective to transport and handle during production. It also helps reduce the overall weight of the storage container, allowing for increased payload capacity and more efficient storage and transportation. During the molding process, the fiberglass mat tissue is typically applied to the surface of the container. It is often impregnated with a resin or adhesive, which, when cured, creates a strong bond with the container, enhancing its structural integrity. Overall, fiberglass mat tissue is crucial for the production of high-quality and long-lasting storage containers. Its strength, durability, corrosion resistance, and weight reduction capabilities make it the preferred choice for manufacturers in this industry.

- Q: Is fiberglass mat tissue suitable for insulation in industrial applications?

- Indeed, fiberglass mat tissue proves to be a suitable option for insulation in industrial settings. With its lightweight and flexible nature, this material showcases exceptional thermal insulation properties. Its ability to efficiently trap and retain heat makes it highly advantageous for insulating industrial machinery and equipment. Moreover, it exhibits commendable fire resistance characteristics, which are particularly critical in environments where fire hazards are more prevalent. Additionally, fiberglass mat tissue demonstrates resistance against corrosion, moisture, and chemicals, ensuring its durability and longevity when employed in industrial applications. Overall, this material's insulation capabilities, fire resistance, and ability to withstand various environmental elements establish fiberglass mat tissue as a suitable choice for industrial insulation needs.

- Q: How does fiberglass mat tissue contribute to the strength and durability of composite materials?

- Fiberglass mat tissue enhances the strength and durability of composite materials by providing reinforcement and structural integrity. The mat tissue consists of randomly arranged fibers that are bonded together, creating a strong and flexible matrix. This matrix acts as a support system, distributing stress and load across the material, thereby preventing cracks and fractures. Additionally, the fiberglass mat tissue acts as a barrier against moisture and other environmental factors, protecting the composite material from degradation and ensuring long-lasting performance.

- Q: What is the lifespan of fiberglass mat tissue?

- The lifespan of fiberglass mat tissue can vary depending on various factors such as the quality of the material, the conditions it is exposed to, and the level of maintenance it receives. However, fiberglass mat tissue is generally known for its durability and long lifespan. With proper installation and regular maintenance, fiberglass mat tissue can last for many decades. It is resistant to corrosion, moisture, and UV radiation, which helps to prolong its lifespan. Additionally, fiberglass mat tissue is often used in applications such as roofing, insulation, and reinforcement, where it is designed to withstand harsh conditions and provide long-term performance.

Send your message to us

Fiberglass Mat Tissue Woven Roving Combo Mat 1100g(300/500/300)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords