Fiberglass Mat Tissue Glass Blanket Glass Wool Building Materials with CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Insulation Blanket:

Glass Wool Blanket Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

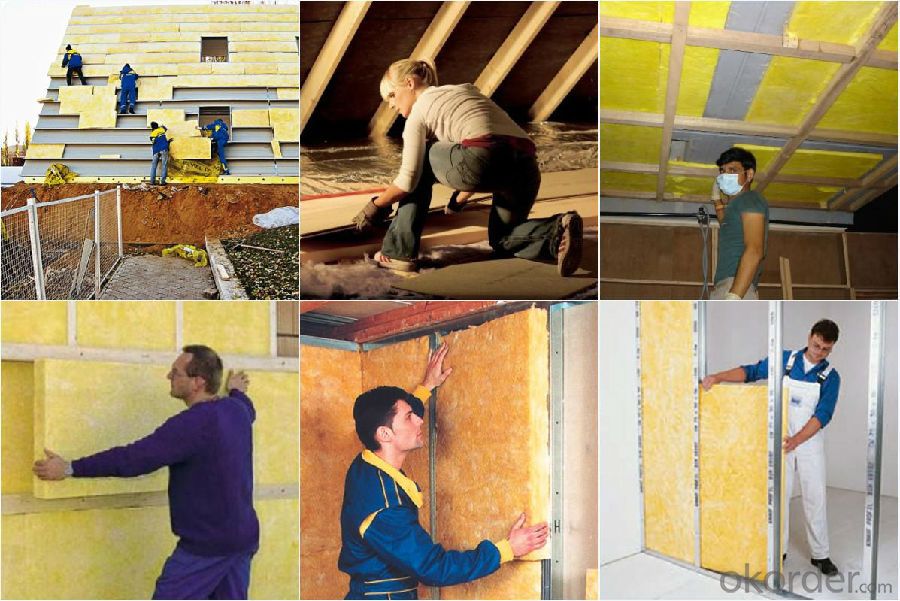

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the typical width of fiberglass mat tissue rolls?

- The typical width of fiberglass mat tissue rolls is around 1 meter or 3 feet.

- Q: Can fiberglass mat tissue be used for insulation boards?

- Insulation boards can indeed utilize fiberglass mat tissue as a viable option. This lightweight and flexible material consists of delicate glass fibers melded together with a resin. Its outstanding thermal insulation qualities make it an optimal selection for insulation boards. The mat tissue is effortlessly customizable, capable of conforming to various shapes and sizes, thereby facilitating insulation of walls, roofs, floors, and other areas within a structure. Notably, it possesses resistance against moisture, mold, and mildew, ensuring enduring insulation performance. Moreover, fiberglass mat tissue exhibits fire-resistant properties, further bolstering its suitability for insulation applications. In summary, fiberglass mat tissue proves to be an adaptable and efficient material for insulation boards.

- Q: Is fiberglass mat tissue biodegradable?

- No, fiberglass mat tissue is not biodegradable. Fiberglass is a synthetic material made from fine fibers of glass, which are woven together to create a strong and durable material. These fibers do not break down naturally over time, making fiberglass mat tissue non-biodegradable.

- Q: Can fiberglass mat tissue be used in high-temperature applications?

- No, fiberglass mat tissue is not suitable for high-temperature applications.

- Q: Does fiberglass mat tissue provide good fire protection?

- No, fiberglass mat tissue does not provide good fire protection.

- Q: What is the maximum temperature that fiberglass mat tissue can withstand?

- The maximum temperature that fiberglass mat tissue can withstand depends on the specific type of fiberglass material being used. Generally, most fiberglass mat tissues are designed to withstand temperatures up to 600 degrees Fahrenheit (315 degrees Celsius). However, it is important to note that the temperature tolerance can vary depending on factors such as the thickness of the material, the manufacturing process, and the specific application. It is always advisable to consult the manufacturer's specifications or technical data sheets for accurate information regarding the maximum temperature resistance of a particular fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for automotive applications?

- Yes, fiberglass mat tissue can be used for automotive applications. It is commonly used in the automotive industry for reinforcement and strength in parts such as body panels, hoods, and interior components. It provides excellent thermal and acoustic insulation properties as well.

- Q: What are the different color options available for fiberglass mat tissue?

- The different color options available for fiberglass mat tissue typically include white, gray, and beige.

- Q: How does the thickness of fiberglass mat tissue affect its performance?

- The performance of fiberglass mat tissue is greatly influenced by its thickness. Thicker mat tissues generally offer superior strength and durability compared to thinner ones. When the mat tissue is thicker, there is a higher proportion of resin to glass, resulting in increased stiffness and toughness. This higher resin content improves the overall structural integrity and mechanical properties of the mat tissue, reducing the risk of delamination and enhancing resistance to impact and fatigue. Furthermore, thicker fiberglass mat tissues are more effective in providing thermal and acoustic insulation. The increased thickness allows for a greater concentration of fibers, enhancing the material's ability to trap air and reduce heat transfer or sound transmission. However, it is important to consider the specific application and requirements when determining the appropriate thickness of fiberglass mat tissue. While thicker tissues generally offer better performance, they may also be heavier and more costly. Therefore, it is crucial to strike a balance between the desired performance characteristics and practical considerations such as weight, cost, and ease of installation.

- Q: Can fiberglass mat tissue be used for insulation?

- Fiberglass mat tissue can indeed be utilized for insulation purposes. It finds widespread application within the construction sector, serving as an effective material for thermal and sound insulation. Comprised of delicate glass fibers intricately woven into a mat-like formation, this tissue structure effectively captures air, establishing a barrier that minimizes heat transfer. Consequently, it ensures insulated spaces retain a pleasant temperature. Moreover, fiberglass mat tissue boasts resistance against moisture, fire, and pests, rendering it an excellent insulation option across diverse situations.

Send your message to us

Fiberglass Mat Tissue Glass Blanket Glass Wool Building Materials with CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords