Fiberglass Mat Tissue Reinforced Glass Blanket Glass Wool Building Materials with CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Insulation Blanket:

Glass Wool Blanket Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

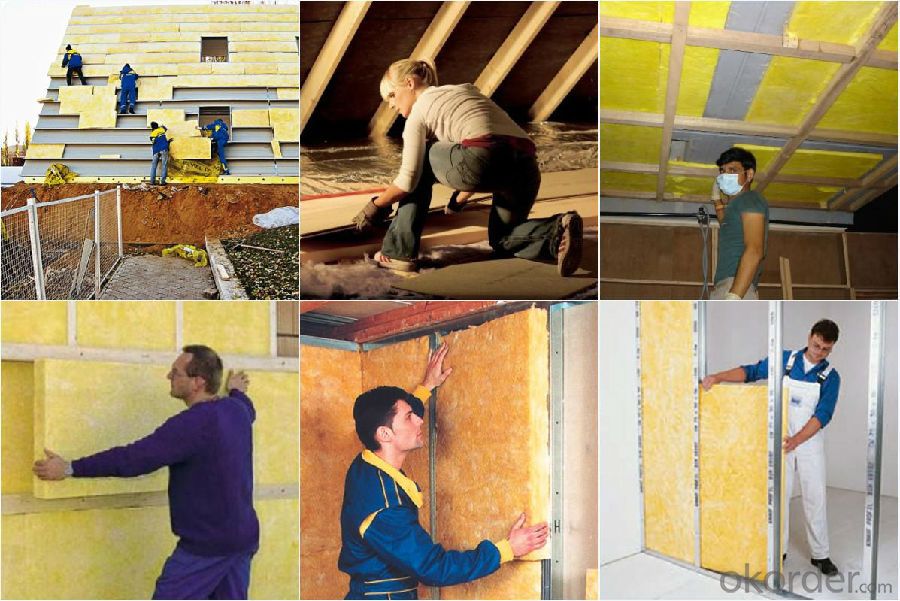

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can fiberglass mat tissue be used for mold making?

- No, fiberglass mat tissue is not typically used for mold making. It is more commonly used in composite manufacturing processes, such as reinforcing fiberglass laminates or repairing damaged fiberglass structures. For mold making, silicone rubber, urethane rubber, or other specialized materials are typically used.

- Q: Does fiberglass mat tissue require any special handling precautions?

- Yes, fiberglass mat tissue does require special handling precautions. Due to its nature, fiberglass mat tissue can release tiny glass fibers into the air when handled incorrectly. These fibers can cause skin irritation, eye irritation, and respiratory issues if inhaled. Therefore, it is important to wear appropriate protective clothing, such as gloves, long-sleeved shirts, pants, and safety goggles, when handling fiberglass mat tissue. It is also advisable to work in a well-ventilated area or use respiratory protection if working in a confined space. Additionally, it is crucial to handle the material gently to avoid any breakage or damage that could release more fibers into the environment. Proper disposal methods should also be followed to prevent any potential harm. Overall, taking these precautions ensures the safety and well-being of individuals handling fiberglass mat tissue.

- Q: Is fiberglass mat tissue resistant to mold growth?

- Yes, fiberglass mat tissue is resistant to mold growth. Fiberglass is made from glass fibers that are tightly woven together, creating a material that is highly resistant to moisture and mold. Additionally, fiberglass is non-porous, meaning it does not absorb water, which further inhibits the growth of mold. This makes fiberglass mat tissue an ideal choice for applications where mold resistance is important, such as in insulation, wallboards, and other construction materials.

- Q: How is fiberglass mat tissue used in the production of chemical reactors?

- Due to its exceptional properties, fiberglass mat tissue is commonly utilized in the production of chemical reactors. Composed of randomly oriented glass fibers bonded together with a binder material, this tissue is ideal for constructing these reactors. A primary application of fiberglass mat tissue in chemical reactors is as a reinforcement material. It is typically applied to the inner surfaces of the reactor to enhance its structural integrity. The combination of glass fibers and binder creates a durable and strong layer capable of withstanding harsh conditions within the reactor, such as high temperatures and corrosive chemicals. Moreover, fiberglass mat tissue acts as a protective barrier against chemical attack. Traditional materials often degrade when exposed to aggressive substances found in chemical reactors. However, the chemical resistance of fiberglass mat tissue makes it highly suitable for such environments. It effectively prevents corrosive chemicals from penetrating the reactor walls, ensuring the long-lasting reliability of the equipment. Additionally, fiberglass mat tissue offers thermal insulation properties to chemical reactors. This is particularly crucial in processes where temperature control is vital. The insulation capabilities of the tissue help maintain the desired temperature within the reactor, preventing heat loss or gain that could negatively impact the efficiency and consistency of chemical reactions. In conclusion, fiberglass mat tissue plays a vital role in the production of chemical reactors by reinforcing the structure, providing chemical resistance, and offering thermal insulation. Its unique properties make it an excellent choice for ensuring the durability, safety, and optimal performance of chemical reactors in various industrial applications.

- Q: What are the applications of fiberglass mat tissue?

- Fiberglass mat tissue is commonly used in various applications, including but not limited to, the construction industry, automotive manufacturing, and the production of composite materials. It is used as a reinforcement material in the construction of walls, roofs, and floors, providing strength and durability. In the automotive industry, fiberglass mat tissue is used for sound insulation and as a reinforcement material in the production of car parts. Additionally, it is widely utilized in the manufacturing of composite materials, such as fiberglass-reinforced plastics, due to its high strength-to-weight ratio and excellent corrosion resistance.

- Q: What are the different types of resins compatible with fiberglass mat tissue?

- Fiberglass mat tissue can be used with various types of resins. These resins, including polyester resin, epoxy resin, vinyl ester resin, and polyurethane resin, offer different properties and benefits. Polyester resin is widely used in fiberglass mat applications due to its cost-effectiveness and good mechanical properties. It is suitable for a wide range of applications and provides resistance to water and chemicals. Working with polyester resin is also easy. Another popular choice is epoxy resin, which offers excellent mechanical properties, high strength, and resistance to chemicals and moisture. It is commonly used in industries that require superior strength and durability, such as aerospace and marine industries. Vinyl ester resin is a hybrid resin that combines the best properties of polyester and epoxy resins. It offers high strength, good corrosion resistance, and excellent durability. This resin is commonly used in applications that require high chemical resistance and superior mechanical properties. Polyurethane resin is a versatile option that can be used with fiberglass mat tissue. It provides excellent flexibility, impact resistance, and adhesion properties. This resin is often used in applications that require high flexibility and resistance to abrasion, such as automotive parts and sporting goods. Ultimately, the selection of the resin depends on specific application requirements, including mechanical properties, chemical resistance, flexibility, and cost.

- Q: Is fiberglass mat tissue suitable for oil and gas applications?

- Indeed, fiberglass mat tissue proves to be fitting for oil and gas applications. This material, renowned for its lightweight yet robust nature, demonstrates resilience in the face of the demanding conditions that typically arise within the oil and gas sector. Its extraordinary resistance to chemicals, including oil and gas, renders it an optimal selection for endeavors like pipeline insulation, tank lining, and filtration systems. Moreover, fiberglass mat tissue showcases exceptional resistance to moisture absorption, possesses commendable thermal insulation characteristics, and can be effortlessly molded into diverse shapes and forms, thereby establishing itself as a versatile substance suitable for a wide range of oil and gas applications.

- Q: What is the abrasion resistance of fiberglass mat tissue?

- The abrasion resistance of fiberglass mat tissue is high, making it suitable for applications that require durability and resistance to wear and tear.

- Q: Can fiberglass mat tissue be used for reinforcing concrete?

- Yes, fiberglass mat tissue can be used for reinforcing concrete. It is often used as a reinforcement material in construction for its high tensile strength and durability. The fiberglass mat tissue helps to increase the overall strength and structural integrity of the concrete, making it suitable for various applications such as building foundations, road pavements, and precast concrete products.

- Q: Can fiberglass mat tissue be painted over?

- Yes, fiberglass mat tissue can be painted over. However, there are a few considerations that need to be taken into account. First, it is important to ensure that the fiberglass mat tissue is clean and free from any dirt, grease, or other contaminants before painting. This can be achieved by cleaning the surface with a mild detergent and water, followed by thorough rinsing and drying. Secondly, it is recommended to apply a primer before painting to improve adhesion and promote a smoother finish. A high-quality primer specifically designed for use on fiberglass surfaces should be used, following the manufacturer's instructions for application. Finally, when choosing the paint, it is crucial to select one that is compatible with fiberglass materials. Acrylic or epoxy-based paints are often recommended as they provide good adhesion and durability on fiberglass surfaces. By following these steps and using appropriate materials, it is possible to paint over fiberglass mat tissue successfully. However, it is always advisable to consult with a professional or follow the manufacturer's recommendations for optimal results.

Send your message to us

Fiberglass Mat Tissue Reinforced Glass Blanket Glass Wool Building Materials with CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords