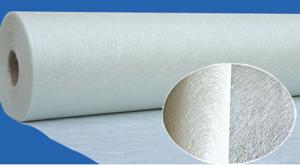

Fiberglass Mat Tissue Fiberglass Woven Roving Combo Mat 1050gsm, 1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Process

Fiberglass stitch combo mat is the mat combining the woven roving and a even layer of chopped strand mat with polyester yarn.

Properties

• Fiber level unfolded without cross, high density, high utilizing rate.

• Multi-layer finished one time, decrease layer and enhance efficiency.

• Providing the product with multi-directional mechanical strength.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: pultrusion, RTM, hand lay up, etc.

• Ultimate products: pultruded profiles, FRP body of boat, insulation board, automobile body.

Specifications

specifications | Fibre type | Wover roving | Chopped strand | Overall weight | Width |

(g/㎡) | (g/㎡) | (g/㎡) | (mm) | ||

EMK 600/300 | E-Glass | 600 | 300 | 900 | 1600/2400 |

EMK 600/380 | E-Glass | 600 | 380 | 980 | 1600/2400 |

EMK 600/450 | E-Glass | 600 | 450 | 1050 | 1600/2400 |

EMK 800/300 | E-Glass | 800 | 300 | 1100 | 1600/2400 |

EMK 800/380 | E-Glass | 800 | 380 | 1180 | 1600/2400 |

EMK 800/450 | E-Glass | 800 | 450 | 1250 | 1600/2400 |

Packaging: Wrapped in PVC and placed within a cardboard carton. | |||||

- Q: Is fiberglass mat tissue suitable for outdoor applications?

- Indeed, outdoor applications are well-suited for fiberglass mat tissue. This particular material is constructed from interwoven fiberglass strands, all effectively bound together by a specialized adhesive. Its exceptional resistance to water, weather, and UV radiation renders it particularly well-suited for deployment in outdoor settings. Its adaptability extends to a range of outdoor applications, including roofing, insulation, and construction projects. The waterproof and weatherproof qualities of fiberglass mat tissue guarantee its robustness and longevity even in the face of harsh environmental conditions. Moreover, its lightweight nature and user-friendly handling characteristics make it a highly versatile option for various outdoor endeavors.

- Q: What is the tear resistance of fiberglass mat tissue?

- The tear resistance of fiberglass mat tissue is typically high, making it a strong and durable material that is resistant to tearing.

- Q: Does fiberglass mat tissue provide good acoustical performance?

- Yes, fiberglass mat tissue does provide good acoustical performance. It has excellent sound absorption properties due to its fibrous composition, which helps reduce echo and improve overall sound quality in a given space.

- Q: Is fiberglass mat tissue resistant to fading?

- Fiberglass mat tissue is generally not resistant to fading. Fading occurs when a material loses its original color or brightness due to exposure to sunlight or other environmental factors. While fiberglass itself is known for its durability and resistance to weathering, the mat tissue used in fiberglass products is often susceptible to fading over time. This can be attributed to the binder or resin used to hold the fiberglass fibers together, as well as the pigments or dyes used to color the tissue. Exposure to UV rays and other outdoor elements can cause these components to break down and fade, resulting in a loss of color intensity or brightness. Therefore, if maintaining the aesthetic appearance of a fiberglass product is important, additional protective measures such as applying a UV-resistant coating or using pigments specifically designed for outdoor use may be necessary.

- Q: Are there any specific certifications or standards that fiberglass mat tissue must meet?

- Yes, there are specific certifications and standards that fiberglass mat tissue must meet in order to ensure its quality and suitability for various applications. One of the most widely recognized standards for fiberglass mat tissue is the ASTM D 4601 standard, which establishes the minimum requirements for glass fiber mats used in roofing and waterproofing systems. This standard covers the physical properties of the mat such as weight, thickness, tensile strength, tear resistance, and water resistance. In addition to ASTM D 4601, there are other certifications and standards that fiberglass mat tissue can be tested against, depending on its intended use. For instance, fiberglass mat tissue used in the automotive industry may need to meet specific standards such as ISO 9001 or IATF 16949, which ensure quality management systems and product consistency. Moreover, fiberglass mat tissue used in construction or building materials may need to comply with standards set by regulatory bodies or organizations such as the International Code Council (ICC), the American National Standards Institute (ANSI), or the Underwriters Laboratories (UL). These standards typically focus on fire resistance, thermal insulation properties, and overall safety. Overall, the specific certifications and standards that fiberglass mat tissue must meet depend on its intended application and the industry in which it is used. These standards play a crucial role in ensuring the quality, performance, and safety of fiberglass mat tissue products.

- Q: Can fiberglass mat tissue be used for repairing damaged fiberglass structures?

- Fiberglass mat tissue is a valuable tool in the repair of damaged fiberglass structures. This versatile material is frequently utilized in both the construction and repair of fiberglass structures. Its thin, flexible nature allows it to be easily shaped and molded to fit any damaged area. Furthermore, its reputation for strength and durability makes it an optimal choice for reinforcing and fortifying weakened fiberglass structures. Boats, car bodies, and other fiberglass products commonly benefit from the application of fiberglass mat tissue in the repair of cracks, holes, and other damages. Moreover, the simple bond between the damaged area and the fiberglass mat tissue can be easily achieved through the use of epoxy or polyester resin, resulting in a robust and long-lasting repair. All in all, fiberglass mat tissue is a dependable and efficient solution for the repair of damaged fiberglass structures.

- Q: How does fiberglass mat tissue enhance the strength of composite materials?

- Fiberglass mat tissue enhances the strength of composite materials by providing reinforcement and stability. It acts as a structural layer that distributes and transfers loads throughout the composite, increasing its overall strength and stiffness. The fiberglass mat tissue's high tensile strength and excellent dimensional stability help prevent cracking, delamination, and deformation in the composite structure, resulting in improved durability and performance.

- Q: Can fiberglass mat tissue be used for reinforcing swimming pools?

- Yes, fiberglass mat tissue can be used for reinforcing swimming pools. It is commonly used in the construction of pool shells to provide added strength and durability.

- Q: Can fiberglass mat tissue be used for insulation in research laboratories?

- Yes, fiberglass mat tissue can be used for insulation in research laboratories. It is a common material choice due to its excellent thermal insulation properties and fire resistance. Additionally, fiberglass mat tissue is lightweight, durable, and easy to install, making it suitable for various insulation applications in laboratories.

- Q: Is fiberglass mat tissue water-resistant?

- Yes, fiberglass mat tissue is water-resistant.

Send your message to us

Fiberglass Mat Tissue Fiberglass Woven Roving Combo Mat 1050gsm, 1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords