Fiberglass Mat Tissue Reinforced Heat/Thermal Insulation Rock Wool Fireproof Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Rock wool insulation board is based on superior melted basalt and diabase as the main raw material, through advanced centrifuge system of four-roller cotton process which pulls melted basaltic rockwool into a 4 ~ 7μm non continuous fibers followed by adding a certain amount of binder, dust laying oil, water repellent before settlement folding, curing, cutting and other processes, and then made into the products of different density depending on purpose of usage.

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1. Excellent thermal insulation

2. Fireproof

3. Good sound absorption property

4. Stable and durable.

5. High acidity coefficient

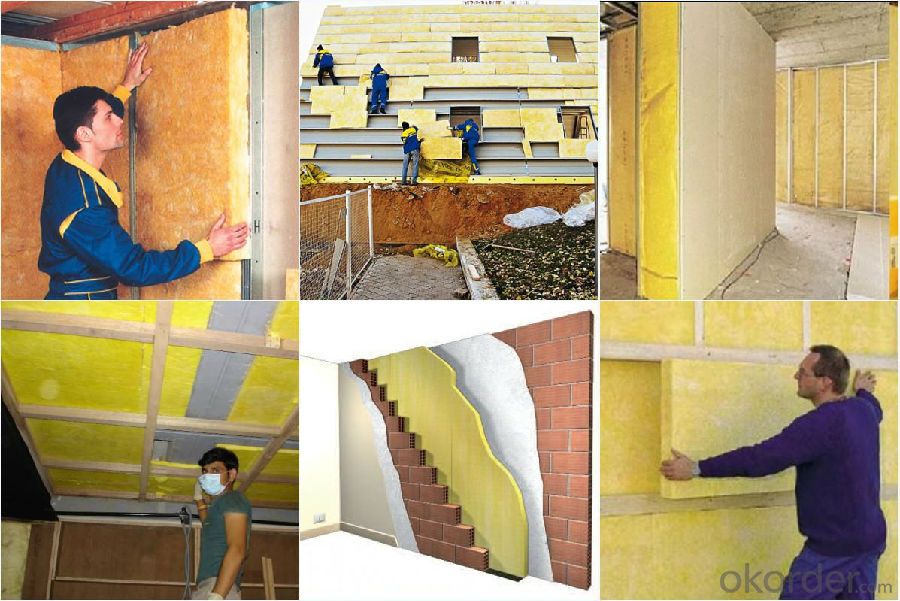

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the expected lifespan of fiberglass mat tissue in power generation applications?

- The expected lifespan of fiberglass mat tissue in power generation applications can vary depending on various factors such as the specific application, environmental conditions, and maintenance practices. However, fiberglass mat tissue is known for its durability and longevity, making it a popular choice for power generation applications. In general, fiberglass mat tissue can have an estimated lifespan of 20 to 30 years in power generation applications. This is due to its excellent resistance to corrosion, heat, and chemicals, which are commonly encountered in power generation facilities. Fiberglass mat tissue is also capable of withstanding high mechanical stress and can retain its structural integrity over a long period of time. However, it is important to note that the lifespan can be influenced by factors such as exposure to extreme temperatures, humidity, and chemicals, as well as the frequency and quality of maintenance and inspections. Regular inspections and proper maintenance can significantly extend the lifespan of fiberglass mat tissue in power generation applications. It is recommended to consult with manufacturers and industry experts to determine the specific expected lifespan of fiberglass mat tissue based on the particular power generation application and operating conditions.

- Q: Does fiberglass mat tissue provide any sound insulation?

- Yes, fiberglass mat tissue does provide sound insulation. It is a common material used in various industries, including construction and automotive, to absorb and reduce sound transmission. The fibrous structure of the material helps to trap and absorb sound waves, preventing them from passing through walls or other surfaces. Fiberglass mat tissue is often used as an acoustic insulation material in walls, floors, and ceilings to create a more comfortable and noise-free environment.

- Q: Can fiberglass mat tissue be used for flooring applications?

- No, fiberglass mat tissue is not typically used for flooring applications. It is commonly used in industries such as automotive, construction, and marine for insulation, reinforcement, and insulation purposes. Flooring applications usually require different materials such as tiles, hardwood, laminate, or vinyl.

- Q: Does fiberglass mat tissue require any special tools for installation?

- Yes, fiberglass mat tissue may require some special tools for installation. These tools can include a utility knife or scissors for cutting the mat to the desired size, a roller or brush for applying adhesive or resin to secure the mat to the desired surface, and safety equipment such as gloves and goggles to protect the installer from potential hazards. Additionally, some installations may require the use of a heat gun or torch to activate or cure the resin. It is important to read and follow the manufacturer's instructions and recommendations for the specific fiberglass mat tissue being used to ensure proper installation and to determine if any special tools are required.

- Q: Can fiberglass mat tissue be used for acoustic panels?

- Yes, fiberglass mat tissue can be used for acoustic panels. It is commonly used as a core material in acoustic panels due to its excellent sound absorption properties. The fibers in the tissue help to dissipate sound energy and reduce echo and reverberation in a room.

- Q: Is fiberglass mat tissue suitable for oil and gas applications?

- Yes, fiberglass mat tissue is suitable for oil and gas applications. Fiberglass mat tissue is a lightweight, strong, and durable material that can withstand the harsh conditions commonly found in the oil and gas industry. It has excellent resistance to chemicals, including oil and gas, making it an ideal choice for applications such as pipeline insulation, tank lining, and filtration systems. Additionally, fiberglass mat tissue has low moisture absorption, good thermal insulation properties, and can be easily fabricated into different shapes and forms, making it a versatile material for various oil and gas applications.

- Q: Can fiberglass mat tissue be used for insulating ductwork?

- Yes, fiberglass mat tissue can be used for insulating ductwork. Fiberglass mat tissue is a type of insulation material that is made from fine glass fibers. It is a lightweight and flexible material that can be easily installed around ductwork to provide thermal insulation. Fiberglass mat tissue has excellent insulating properties and can help prevent heat loss or gain in ducts, improving energy efficiency. It also helps to reduce condensation and dampen noise transmission. Furthermore, fiberglass mat tissue is resistant to moisture, fire, and pests, making it a suitable choice for insulating ductwork in various environments.

- Q: Can fiberglass mat tissue be used in automotive manufacturing?

- Yes, fiberglass mat tissue can be used in automotive manufacturing. Fiberglass mat tissue is a lightweight, flexible material made from glass fibers that are bonded together with a binder. It is commonly used in the automotive industry for various applications such as reinforcing body panels, creating structural components, and improving sound and heat insulation. One of the main advantages of using fiberglass mat tissue in automotive manufacturing is its high strength-to-weight ratio. It provides excellent reinforcement properties while adding minimal weight to the vehicle, making it an ideal choice for achieving fuel efficiency and reducing emissions. Additionally, fiberglass mat tissue is highly moldable, allowing it to be easily shaped and formed into complex geometries required for automotive parts. This material can be used to reinforce areas that are susceptible to high stress, such as the roof, doors, and undercarriage, thereby enhancing the overall strength and durability of the vehicle. Moreover, fiberglass mat tissue offers excellent resistance to corrosion, chemicals, and extreme temperatures, making it suitable for use in diverse automotive environments. It is also an effective sound and heat insulator, helping to reduce noise and maintain a comfortable interior temperature. Overall, fiberglass mat tissue has proven to be a valuable material in automotive manufacturing due to its lightweight, strong, moldable, and durable properties. Its versatility and performance characteristics make it a preferred choice for many automotive manufacturers looking to enhance the quality and performance of their vehicles.

- Q: Can fiberglass mat tissue be used for wall insulation?

- Wall insulation can indeed utilize fiberglass mat tissue. This lightweight and flexible material is frequently employed for thermal and acoustic insulation in buildings. It is composed of fine glass fibers that are woven together to form a mat. This mat is subsequently used as an insulation layer, either in the form of rolls or batts, which is positioned between the wall structure and the finished wall surface. The efficacy of fiberglass mat tissue as an insulation material derives from its high resistance to heat transfer. It effectively prevents heat loss during winter and heat gain during summer, thereby reducing energy consumption and maintaining a comfortable indoor temperature. Additionally, it functions as a sound barrier, diminishing noise transmission between rooms and from external sources. Moreover, fiberglass mat tissue is non-combustible, meaning it does not contribute to the spread of fire. Consequently, it is a safe choice for wall insulation, as it hinders the progression of a fire and allows occupants valuable time to evacuate. Aside from its insulation properties, fiberglass mat tissue is also simple to install. It can be easily cut to size and fitted into wall cavities, ensuring a snug and efficient insulation layer. Furthermore, it is durable and long-lasting, providing insulation benefits for many years. In summary, fiberglass mat tissue is a suitable option for wall insulation due to its thermal and acoustic properties, fire resistance, ease of installation, and durability.

- Q: How is fiberglass mat tissue different from fiberglass cloth?

- Fiberglass mat tissue and fiberglass cloth are both materials made of woven glass fibers, but they have some key differences. Fiberglass mat tissue is a non-woven material that consists of randomly oriented glass fibers held together by a binder material. It is typically used as a reinforcement layer in composite materials such as fiberglass reinforced plastic (FRP) or fiberglass reinforced concrete (FRC). The random orientation of the fibers provides strength and stability to the composite structure. Fiberglass mat tissue is commonly used in applications where strength and rigidity are important, such as boat hulls or automotive parts. On the other hand, fiberglass cloth is a woven material that is made by interlacing glass fibers together in a specific pattern. It is commonly used for applications where flexibility and conformability are important, such as in the construction of surfboards or in the aerospace industry. Fiberglass cloth allows for more precise and controlled placement of fibers, making it suitable for creating complex shapes and achieving a higher level of detail in the final product. Overall, the main difference between fiberglass mat tissue and fiberglass cloth lies in their structural characteristics and intended applications. Fiberglass mat tissue offers strength and stability, while fiberglass cloth provides flexibility and conformability. The choice between these materials depends on the specific requirements of the project and the desired outcome.

Send your message to us

Fiberglass Mat Tissue Reinforced Heat/Thermal Insulation Rock Wool Fireproof Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords