Fiberglass Mat Tissue - E-Glass Fiberglass Woven Roving, 600g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of woven roving Description

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

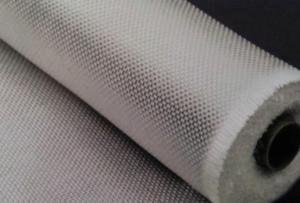

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

Application of Fiberglass Woven Roving:

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyeser,vinylester and epoxy resins

- Q: Is fiberglass mat tissue suitable for automotive body panel repairs?

- Yes, fiberglass mat tissue is suitable for automotive body panel repairs. Fiberglass mat tissue is a versatile material that is commonly used in automotive repairs due to its strength, durability, and flexibility. It is particularly effective in repairing body panels as it can be molded and shaped to fit the unique contours of the vehicle. Additionally, fiberglass mat tissue is resistant to corrosion, moisture, and chemicals, making it an ideal choice for automotive applications. Its lightweight nature also helps to minimize the overall weight of the vehicle, improving fuel efficiency. Overall, fiberglass mat tissue is a reliable and effective material for automotive body panel repairs.

- Q: What is the fire rating of fiberglass mat tissue?

- The fire rating of fiberglass mat tissue differs based on its specific composition and the standards it has been tested against. Typically, fiberglass mat tissue is engineered to possess fire-resistant qualities, but the actual fire rating relies on variables like the tissue's thickness and any supplementary fire retardant coatings or treatments. To ascertain the fire rating of a particular fiberglass mat tissue product, it is advisable to refer to the manufacturer's specifications or test reports, as they offer the most precise and current information available.

- Q: Does fiberglass mat tissue provide any UV resistance?

- Yes, fiberglass mat tissue typically provides some level of UV resistance. The fiberglass mat tissue is made up of glass fibers that are embedded in a matrix of resin. These fibers and resin provide some degree of protection against UV radiation from the sun. However, it is important to note that the level of UV resistance may vary depending on the specific composition and manufacturing process of the fiberglass mat tissue. Additionally, prolonged exposure to UV radiation can still cause some degradation over time, so it is recommended to take appropriate measures such as using UV-resistant coatings or finishes to enhance the durability and lifespan of the fiberglass mat tissue in outdoor applications.

- Q: Does anyone know the hardness value of the heat conductive gasket? Does it contain the hardness of the carrier (glass fiber)?

- SHORE hardness is only for the hardness of the heat conductive gasket itself

- Q: How is fiberglass mat tissue used in the production of water tanks?

- Fiberglass mat tissue is used in the production of water tanks to provide reinforcement and durability. It is applied as a layer between the inner and outer walls of the tank to enhance its structural integrity and prevent leakage. The fiberglass mat tissue acts as a barrier against corrosion, increases the tank's resistance to external factors such as temperature changes and chemicals, and improves its overall strength.

- Q: What is the weathering resistance of fiberglass mat tissue?

- Fiberglass mat tissue is renowned for its high weathering resistance. It is composed of a blend of fiberglass strands and a binder material, such as polyester or acrylic. This combination produces a sturdy and resilient material that can withstand a range of weathering factors, such as sunlight, moisture, and temperature fluctuations. The fiberglass strands within the mat tissue offer exceptional mechanical strength, preventing the material from succumbing to external stress or pressure. This strength enables the mat tissue to endure the impact of wind, rain, and other weather elements without sustaining significant damage. Moreover, the binder material utilized during the manufacturing process of fiberglass mat tissue is often specially formulated to resist UV radiation. This UV resistance effectively shields the material from degradation and fading caused by prolonged exposure to sunlight. It also contributes to maintaining the structural integrity and strength of the mat tissue over time. Furthermore, fiberglass mat tissue exhibits resistance to moisture and water absorption. This resistance ensures that the material does not weaken or deteriorate when exposed to rain, humidity, or other sources of moisture. Consequently, the mat tissue remains intact and retains its performance properties even in wet or humid conditions. Overall, fiberglass mat tissue boasts excellent weathering resistance, making it a highly sought-after option for various applications that demand durability and longevity in outdoor environments.

- Q: What are the different grades of fiberglass mat tissue available?

- In the market, you can find various grades of fiberglass mat tissue. These grades differ in terms of their weight, thickness, and strength. The most popular grades include lightweight, medium-weight, and heavyweight fiberglass mat tissue. When it comes to lightweight fiberglass mat tissue, it is generally thinner and lighter compared to other grades. It is commonly used in situations where flexibility and easy handling are important. This grade is suitable for projects like laminating lightweight structures, making molds, and doing repairs. If you're looking for a versatile option that offers a balance between strength and flexibility, medium-weight fiberglass mat tissue is the way to go. It is widely used in boat building, automotive repairs, and general fiberglass reinforcement. This grade provides sufficient strength while still being manageable to work with. On the other hand, if you need superior strength and durability, heavyweight fiberglass mat tissue is the grade for you. It is the thickest and heaviest grade available in the market. This grade is perfect for applications that require high structural integrity, such as construction, aerospace, and marine industries. Apart from these standard grades, there may be variations and special grades available depending on the manufacturer and the specific requirements of your project. It is crucial to consult with a supplier or manufacturer to determine the most suitable grade of fiberglass mat tissue for your particular application.

- Q: Is fiberglass mat tissue recyclable?

- Indeed, fiberglass mat tissue can be recycled. It is crafted from a fusion of glass fibers and typically resin, serving as a binding material. Once the material becomes unnecessary or completes its life span, it can undergo recycling by disassembling the glass fibers from the binder material. Subsequently, the glass fibers can be liquefied and utilized in the production of novel fiberglass goods, while the binder material can be processed and repurposed in alternative applications. The act of recycling fiberglass mat tissue aids in waste reduction and the preservation of natural resources, rendering it a sustainable choice.

- Q: Is fiberglass mat tissue resistant to acids?

- Yes, fiberglass mat tissue is generally resistant to acids.

- Q: Can fiberglass mat tissue be used for insulation in research laboratories?

- Yes, fiberglass mat tissue can be used for insulation in research laboratories. It is a common material choice due to its excellent thermal insulation properties and fire resistance. Additionally, fiberglass mat tissue is lightweight, durable, and easy to install, making it suitable for various insulation applications in laboratories.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiberglass Woven Roving, 600g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords