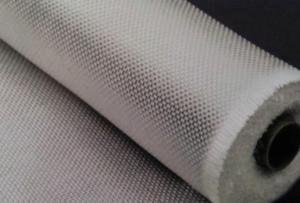

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 500g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Woven Roving

1)Low Fuzz

2)Fast Wet-out&Impregnation

3)Easy Lay-up&Air Release

4)Excellent Mechanical Strength

Main Features of Woven Roving

1.CWR400

2.360-380g/m2

3.77.5px or 2250px width

4.plastic woven bag

Application of Woven Roving

Unit | Product No. | Weight(gsm) | Technique | Moisture content | combustible matter content(%) |

M | EWR260 | 264±13 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR270 | 261±13.5 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR360 | 354±18 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR500 | 504±25 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR580 | 576±29 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR600 | 622±30 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR800 | 850±40 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR200 | 200±15 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR400 | 385±30 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR600 | 600±45 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR800 | 810±40 | Plain | ≤0.15 | 0.40-0.80 |

Images:

FAQ of Woven Roving

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: How long does fiberglass mat tissue last?

- The lifespan of fiberglass mat tissue can vary depending on various factors such as its quality, usage, and exposure to external conditions. Generally, fiberglass mat tissue is designed to be highly durable and long-lasting. When properly installed and maintained, it can typically last for several decades. However, it is important to note that fiberglass mat tissue can deteriorate over time due to environmental factors such as UV exposure, moisture, and temperature fluctuations. Continuous exposure to harsh weather conditions, extreme temperatures, or chemicals can accelerate the degradation process. To maximize the lifespan of fiberglass mat tissue, it is crucial to follow the manufacturer's guidelines for installation, maintenance, and periodic inspections. Regular inspections can help identify any signs of wear, damage, or degradation early on, allowing for timely repairs or replacements. It is recommended to consult with a professional or the manufacturer for specific information regarding the expected lifespan of a particular fiberglass mat tissue, as it can vary depending on the specific product and its intended application.

- Q: Is fiberglass mat tissue fire-resistant?

- Yes, fiberglass mat tissue is fire-resistant.

- Q: Can fiberglass mat tissue be used for making insulation blankets?

- Indeed, insulation blankets can be created by utilizing fiberglass mat tissue. This lightweight and flexible material is frequently employed in insulation scenarios. It possesses remarkable thermal insulation characteristics, as well as the ability to withstand fire, moisture, and chemicals. Moreover, fiberglass mat tissue is effortlessly manageable and installable, rendering it an optimal selection for fabricating insulation blankets applicable across diverse industries, including construction, automotive, and aerospace.

- Q: What are the main applications of fiberglass mat tissue?

- Fiberglass mat tissue, an adaptable material, finds diverse applications in industries like construction, automotive, aerospace, and marine. Key uses of this material comprise: 1. Construction: Fiberglass mat tissue commonly reinforces and strengthens building materials in the construction industry, including roofing shingles, wallboards, and cementitious products. It enhances tensile strength and durability, rendering the structures more resistant to cracks, water damage, and weathering. 2. Automotive: The manufacturing of automotive parts, such as dashboards, door panels, and trunk liners, heavily relies on fiberglass mat tissue. It imparts structural integrity, sound insulation, and heat resistance, contributing to safer and more comfortable vehicles. 3. Aerospace: Lightweight composite materials used in aircraft structures benefit from the inclusion of fiberglass mat tissue. This material aids in reducing overall weight, improving fuel efficiency, and enhancing performance. 4. Marine: Fiberglass mat tissue plays a significant role in boat and shipbuilding. It provides strength, stiffness, and resistance to water and corrosion in the construction of hulls, decks, and other components. Its lightweight, durability, and low maintenance requirements make it preferable to traditional materials like wood. 5. Electrical and Electronics: Fiberglass mat tissue serves electrical insulation purposes, such as transformer boards, electrical cabinets, and switchgear. Its excellent dielectric properties, heat resistance, and mechanical strength ensure the safety and reliability of electrical equipment. 6. Filtration: Various filtration applications, such as air filters, water filters, and oil filters, employ fiberglass mat tissue. It acts as a filtration medium, capturing and eliminating impurities, dust, and particles from air, water, or oil, thereby enhancing the quality and purity of filtered substances. In summary, fiberglass mat tissue finds extensive use across industries due to its strength, durability, lightweight nature, and resistance to environmental factors. Its versatility enables it to be an indispensable component in diverse applications, contributing to the development of safer, sturdier, and more efficient products.

- Q: Is fiberglass mat tissue suitable for railway infrastructure?

- Yes, fiberglass mat tissue is suitable for railway infrastructure. Fiberglass mat tissue is a strong and durable material that offers excellent resistance to corrosion, weathering, and chemical degradation. It is commonly used in the construction industry for reinforcing structures such as bridges, tunnels, and platforms. In the case of railway infrastructure, fiberglass mat tissue can provide several benefits. Firstly, it has high tensile strength, which means it can withstand the heavy loads and vibrations associated with train traffic. This helps to prevent cracking and structural damage, ensuring the longevity and safety of the railway system. Additionally, fiberglass mat tissue is non-conductive, which is a crucial characteristic for railway infrastructure. It helps to prevent the risk of electrical shocks and short circuits, which are common concerns in rail networks. This makes fiberglass mat tissue a reliable choice for railway infrastructure, especially in areas where electrical lines are present. Furthermore, fiberglass mat tissue is lightweight and easy to handle, making it convenient for installation in railway projects. It is also resistant to fire, making it a safe choice for railway infrastructure in terms of fire protection. Overall, fiberglass mat tissue is a suitable material for railway infrastructure due to its strength, durability, non-conductive nature, and fire resistance. Its use in railway construction can contribute to the reliability, longevity, and safety of the railway system.

- Q: What are the properties of fiberglass mat tissue?

- Fiberglass mat tissue possesses several key properties that make it highly versatile and widely used in various industries. Firstly, it is lightweight, which enables easy handling and installation. It is also flexible, allowing it to conform to various shapes and contours. Additionally, fiberglass mat tissue is highly durable and possesses excellent tensile strength, making it resistant to tearing or breaking. It is also resistant to corrosion, moisture, and chemicals, making it suitable for applications in harsh environments. Lastly, it has excellent thermal and electrical insulation properties, making it an ideal choice for applications requiring heat or electrical resistance.

- Q: Is fiberglass mat tissue compatible with different adhesives?

- Yes, fiberglass mat tissue is compatible with different adhesives. Fiberglass mat tissue is a versatile material that can be used in various applications such as construction, automotive, and aerospace industries. It is commonly used as a reinforcement material in composites, where it is combined with resin and adhesive to create strong and durable structures. The compatibility of fiberglass mat tissue with different adhesives depends on several factors such as the type of adhesive, the specific application, and the desired performance requirements. Fiberglass mat tissue can be compatible with a wide range of adhesives including epoxy, polyester, vinyl ester, and polyurethane adhesives. It is important to consider the specific properties and characteristics of the adhesive and the fiberglass mat tissue when selecting the adhesive for a particular application. Factors such as curing time, viscosity, bond strength, and chemical resistance should be taken into account to ensure optimal adhesion and performance. In some cases, surface treatment or priming may be necessary to enhance the compatibility between the fiberglass mat tissue and the adhesive. This can involve applying a primer or using a specific surface treatment method to promote adhesion and ensure a strong bond between the two materials. Overall, fiberglass mat tissue is compatible with different adhesives, but it is crucial to consider the specific requirements of the application and select the appropriate adhesive and surface treatment method to achieve the desired results.

- Q: Can fiberglass mat tissue be used for repairing automotive parts?

- Yes, fiberglass mat tissue can be used for repairing automotive parts. It is commonly used in automotive repairs as it provides strength and durability to the repaired area. The mat tissue can be applied with resin to reinforce damaged or weakened sections of automotive parts, making it an effective solution for repairing various components.

- Q: Can fiberglass mat tissue be used for ballistic protection?

- While fiberglass mat tissue can offer some degree of ballistic protection, it may not provide the same level of safety as materials specifically created for this purpose. Its exceptional strength and resistance to heat make it ideal for insulation, reinforcement, and fire resistance applications. Nevertheless, when it comes to shielding against ballistic threats, there are specialized materials engineered to endure the impact of bullets or projectiles. These materials, such as aramid fibers (like Kevlar) or ultra-high-molecular-weight polyethylene fibers (like Dyneema), are far more effective in delivering superior ballistic protection. Therefore, if the primary concern is ballistic protection, it is advisable to opt for materials designed explicitly for this purpose rather than relying solely on fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for making decorative panels?

- Yes, fiberglass mat tissue can be used for making decorative panels. Fiberglass mat tissue is a versatile material that is commonly used in the construction and manufacturing industries. It is made up of randomly oriented glass fibers that are bonded together with a binder. This combination of fiberglass and binder creates a strong and durable material that is suitable for a wide range of applications. When it comes to decorative panels, fiberglass mat tissue can be an excellent choice. It can be molded into various shapes and sizes, allowing for the creation of intricate and unique designs. The material is also lightweight, making it easy to handle and install. Additionally, fiberglass mat tissue has excellent dimensional stability, meaning that it will not warp or deform over time. Furthermore, fiberglass mat tissue is highly resistant to moisture, chemicals, and UV radiation, making it ideal for both indoor and outdoor applications. It can withstand harsh weather conditions and is not susceptible to rot or decay. This durability ensures that decorative panels made from fiberglass mat tissue will maintain their appearance and functionality for an extended period. In terms of finishing, fiberglass mat tissue can be easily painted or coated to achieve the desired aesthetic. It can also be laminated with other materials, such as wood veneer or decorative films, to enhance its visual appeal. This flexibility allows for endless design possibilities, making fiberglass mat tissue an excellent choice for creating decorative panels. In summary, fiberglass mat tissue is a suitable material for making decorative panels. Its strength, durability, and versatility make it a reliable choice for both indoor and outdoor applications. Whether you are looking to create unique designs or enhance the aesthetics of a space, fiberglass mat tissue can provide the necessary qualities to achieve your desired outcome.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 500g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords