Fiberglass Mat Tissue Glass Wool Insulation Blanket CNBM Glass Wool Building Materials with CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Insulation Blanket:

Glass Wool Blanket Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

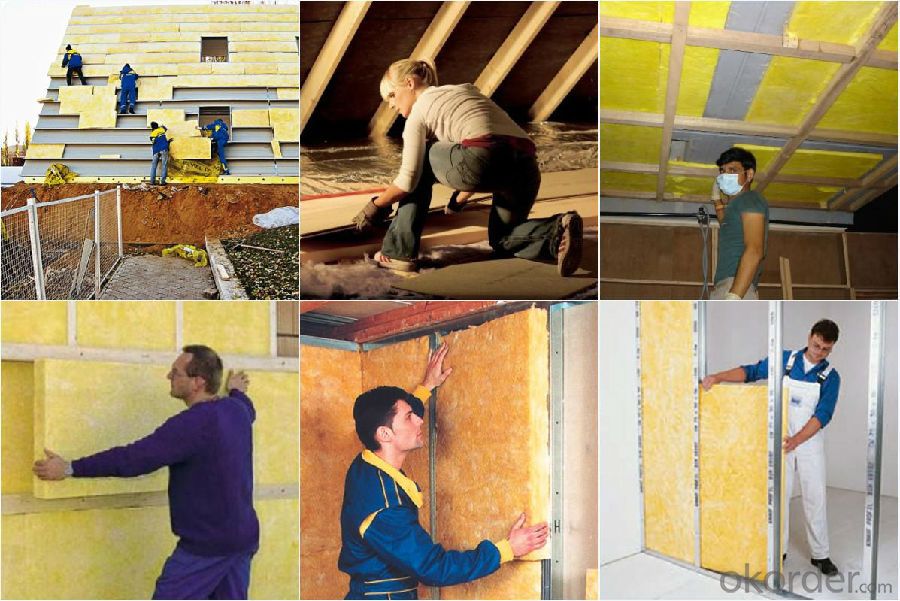

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can fiberglass mat tissue be used as a reinforcement in concrete?

- Yes, fiberglass mat tissue can be used as a reinforcement in concrete. It provides additional strength and durability to the concrete structure by improving crack resistance and reducing shrinkage.

- Q: Can fiberglass mat tissue be used for swimming pool construction?

- Yes, fiberglass mat tissue can be used for swimming pool construction. It is commonly used as a reinforcement material to provide strength and durability to the pool structure.

- Q: Is fiberglass mat tissue resistant to moisture vapor transmission?

- Indeed, fiberglass mat tissue exhibits resistance to the transmission of moisture vapor. It serves as a remarkably robust and moisture-resistant substance, frequently employed in a multitude of scenarios that prioritize moisture management, including roofing, insulation, and flooring. The design of the fiberglass mat tissue is specifically tailored to impede the passage of moisture vapor, thereby preserving the quality and functionality of the accompanying materials. Given its capacity to resist the transmission of moisture vapor, the fiberglass mat tissue emerges as an optimal selection for environments where moisture control is of utmost importance.

- Q: Can fiberglass mat tissue be used for marine applications?

- Yes, fiberglass mat tissue can be used for marine applications. It is commonly used in boat building and repair due to its excellent strength, durability, and resistance to water and corrosion. The fiberglass mat tissue helps reinforce the structure of marine vessels and provides added protection against the harsh marine environment.

- Q: Is fiberglass mat tissue suitable for insulation in data centers?

- Yes, fiberglass mat tissue is a suitable material for insulation in data centers. It provides excellent thermal insulation properties, helping to maintain the desired temperature and prevent heat loss. Additionally, fiberglass is fire-resistant and can offer acoustic insulation, reducing noise levels in the data center. Overall, fiberglass mat tissue is a reliable and effective choice for insulation in data centers.

- Q: Can fiberglass mat tissue be used for wind turbine blades?

- Yes, fiberglass mat tissue can be used for wind turbine blades. Fiberglass mat tissue is a lightweight and strong material that is commonly used in the construction of wind turbine blades. It provides excellent strength-to-weight ratio and is resistant to corrosion, making it ideal for withstanding the harsh environmental conditions that wind turbine blades are exposed to. Additionally, fiberglass mat tissue can be easily molded into complex shapes, allowing for the creation of aerodynamically efficient wind turbine blades. Overall, the use of fiberglass mat tissue in wind turbine blades helps to improve their performance and durability.

- Q: Can fiberglass mat tissue be used for making surfboards?

- Yes, fiberglass mat tissue can be used for making surfboards. Fiberglass mat tissue is a lightweight and strong material that is commonly used in the construction of surfboards. It is typically layered with epoxy resin to create a durable and rigid surface. The fiberglass mat tissue provides strength and flexibility to the surfboard, allowing it to withstand the pressures and forces experienced while riding waves. Additionally, the smooth and sleek surface of the fiberglass mat tissue helps to enhance the performance and speed of the surfboard. Overall, fiberglass mat tissue is a popular choice for surfboard construction due to its excellent strength-to-weight ratio and ability to create high-performance boards.

- Q: Can fiberglass mat tissue be used for repairing automotive parts?

- Certainly, automotive parts can be repaired using fiberglass mat tissue. This versatile material is commonly employed to reinforce and repair various surfaces, including automotive components. It proves particularly valuable when restoring fiberglass parts such as car bodies and panels. Fiberglass mat tissue possesses a thin and flexible composition, comprised of randomly arranged fiberglass strands. This design enables easy molding and shaping to match the contours of the damaged automotive part. Typically, the mat tissue is applied alongside a resin like polyester or epoxy, which binds the fibers together, yielding a robust and enduring repair. When utilized for automotive repairs, fiberglass mat tissue offers numerous advantages. Firstly, its lightweight nature is crucial for maintaining the overall weight and balance of the vehicle. Furthermore, it exhibits resistance to corrosion and can withstand exposure to diverse weather conditions, rendering it suitable for all automotive repair applications. Moreover, fiberglass mat tissue is renowned for its high tensile strength, enabling it to endure the stresses and strains encountered during normal use of automotive parts. As a result, it becomes an ideal choice for fixing damaged or weakened areas, such as cracks, holes, or dents in car bodies or panels. In conclusion, fiberglass mat tissue is a highly effective option for repairing automotive parts, especially those constructed from fiberglass. Its versatility, lightweight composition, corrosion resistance, and high tensile strength make it an exceptional choice for restoring the structural integrity and appearance of damaged automotive components.

- Q: Is fiberglass mat tissue suitable for HVAC insulation?

- Yes, fiberglass mat tissue is suitable for HVAC insulation. It is commonly used in HVAC systems to provide thermal insulation and improve energy efficiency. Fiberglass mat tissue is lightweight, flexible, and has excellent thermal properties, making it an ideal choice for insulating HVAC ducts, pipes, and equipment. It also helps in reducing heat transfer, preventing condensation, and improving overall system performance.

- Q: What is the expected lifespan of fiberglass mat tissue in sports facility applications?

- The expected lifespan of fiberglass mat tissue in sports facility applications can vary depending on various factors such as the quality of the material, the level of maintenance and care, and the specific conditions in which it is used. However, generally speaking, fiberglass mat tissue has a relatively long lifespan and is known for its durability. When properly installed and maintained, fiberglass mat tissue can last for several decades. It is resistant to corrosion, rot, and degradation, making it suitable for use in sports facilities where it may be exposed to moisture, humidity, and other environmental factors. To maximize the lifespan of fiberglass mat tissue in sports facility applications, regular inspections, cleanings, and repairs may be necessary. It is also important to follow manufacturer recommendations for installation and maintenance to ensure optimal performance and longevity. It is worth noting that while fiberglass mat tissue is known for its durability, it may still experience wear and tear over time, especially in high-impact areas or in facilities with heavy usage. In such cases, periodic replacements or repairs may be required to maintain the integrity and functionality of the material. Overall, fiberglass mat tissue is a reliable and long-lasting option for sports facility applications, and with proper care and maintenance, it can provide excellent performance and durability for many years.

Send your message to us

Fiberglass Mat Tissue Glass Wool Insulation Blanket CNBM Glass Wool Building Materials with CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords