Heat Insulation Aluminum Foil Facing glass wool,aluminum foil insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

It is a kind of elastic glass fiber product made of glass fiber with diameter of only a few microns, and we can also choose moisture-proof facing on-line compound according to customers' requirements. Because of a large number of tiny air interspaces, it has the functions of heat insulation, sound absorption, safe guarding and etc, so it is the best materials of heat insulation and sound absorption in construction.

2.Main features of Glass Wool Blanket:

• Soft and long glass fibers can maximally lessen flying catkins in the construction.

• Sound absorption and noise reduction; it can effectively prevent sound from spreading.

• Grade A1 incombustible materials.

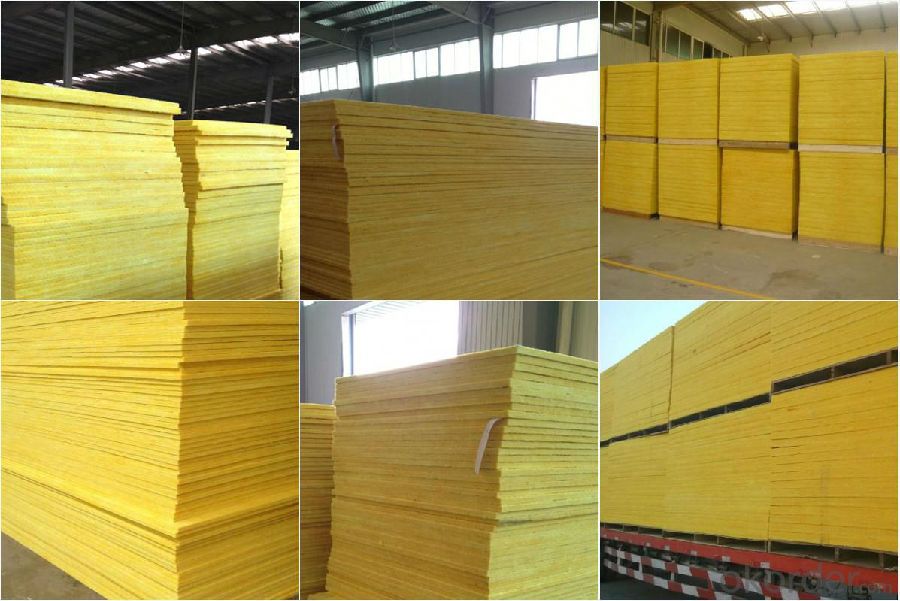

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is fiberglass mat tissue suitable for outdoor applications?

- Yes, fiberglass mat tissue is suitable for outdoor applications. Fiberglass mat tissue is made from woven fiberglass strands that are held together with a binder. This material is highly resistant to water, weather, and UV radiation, making it ideal for use in outdoor environments. It can be used in various outdoor applications such as roofing, insulation, and construction. The waterproof and weatherproof properties of fiberglass mat tissue ensure its durability and longevity when exposed to the elements. Additionally, it is lightweight and easy to handle, making it a versatile choice for outdoor projects.

- Q: Is fiberglass mat tissue suitable for agricultural applications?

- Certainly! Fiberglass mat tissue proves to be a suitable option for agricultural uses. Its versatility makes it an ideal material in the agricultural sector, providing numerous advantages. The resistance of fiberglass mat tissue to moisture, chemicals, and UV radiation makes it perfect for applications like greenhouse roofing, animal enclosures, and agricultural equipment. It possesses exceptional insulation properties, aiding in the regulation of temperature and safeguarding crops or livestock against harsh weather conditions. Moreover, fiberglass mat tissue is lightweight, easy to install, and long-lasting, making it an economical choice for agricultural projects. In conclusion, fiberglass mat tissue is a fitting material for a wide range of agricultural applications, ensuring durability, flexibility, and safeguarding for the farming industry.

- Q: How does fiberglass mat tissue compare to mineral wool insulation?

- Construction and other industries commonly use fiberglass mat tissue and mineral wool insulation as insulation materials. While both serve the purpose of providing thermal insulation, there are differences between them. Fiberglass mat tissue consists of bonded fine glass fibers that form a lightweight and flexible mat. This makes it easy to handle and install. It is also resistant to moisture, mold, and pests, making it a durable option. Its high R-value, which measures heat flow resistance, makes it an effective insulator. On the other hand, mineral wool insulation is made from natural minerals like basalt, diabase, or slag. It is usually denser and heavier than fiberglass mat tissue. Mineral wool insulation has excellent fire resistance properties and can withstand high temperatures. It also provides sound insulation, reducing noise transmission. However, it can absorb moisture, which may decrease its effectiveness over time. Both materials offer similar levels of insulation in terms of thermal performance. However, fiberglass mat tissue is slightly more efficient due to its higher R-value. Additionally, it is generally more affordable compared to mineral wool insulation. In conclusion, fiberglass mat tissue and mineral wool insulation are both effective insulation materials. The choice between them depends on specific project requirements, such as fire resistance, sound insulation, cost, and moisture resistance. It is crucial to consider these factors and seek professional advice to determine the most suitable insulation material for a particular application.

- Q: Is fiberglass mat tissue suitable for sound absorption?

- Fiberglass mat tissue is indeed appropriate for sound absorption. Its exceptional acoustic properties make it a highly efficient material for decreasing noise levels and enhancing sound quality in different settings. The fibrous composition of the mat tissue offers a large surface area capable of absorbing sound waves and converting them into heat energy. This renders it an optimal choice for soundproofing walls, ceilings, and floors in buildings, as well as for automotive, industrial, and marine applications. Moreover, fiberglass mat tissue is lightweight, simple to install, and possesses excellent durability and fire resistance, further augmenting its aptness for sound absorption objectives.

- Q: What is the expected lifespan of fiberglass mat tissue in cryogenic applications?

- The expected lifespan of fiberglass mat tissue in cryogenic applications can vary depending on various factors such as the specific temperature, exposure time, and the quality of the material. However, in general, fiberglass mat tissue is known for its durability and resistance to extreme temperatures, making it suitable for long-term use in cryogenic applications. With proper installation and maintenance, it can potentially last for several years or even decades in such environments.

- Q: Is fiberglass mat tissue suitable for HVAC insulation?

- Fiberglass mat tissue is indeed a suitable material for HVAC insulation. It is a lightweight and flexible substance commonly utilized in insulation applications due to its exceptional thermal insulation properties. With its effective heat insulation, it assists in maintaining a comfortable and energy-efficient environment within HVAC systems. Moreover, fiberglass mat tissue's resistance to moisture prevents the growth of mold or mildew, making it an appropriate choice for HVAC insulation in areas where condensation and moisture may occur. Its easy installation and ability to be cut to fit around HVAC components ensure a proper and secure insulation seal. In summary, fiberglass mat tissue is a dependable and long-lasting insulation material extensively employed in HVAC systems to enhance energy efficiency and thermal performance.

- Q: Can fiberglass mat tissue be used for making boat hulls?

- Yes, fiberglass mat tissue can be used for making boat hulls. It is commonly used in boat manufacturing due to its strength, durability, and ability to provide structural reinforcement.

- Q: What are the advantages of using fiberglass mat tissue in construction?

- There are several advantages of using fiberglass mat tissue in construction. Firstly, it provides excellent strength and durability, making it highly resistant to impacts and weather conditions. Additionally, it has a high tensile strength, allowing it to withstand heavy loads without deformation. Fiberglass mat tissue is also lightweight, making it easier to handle and transport. Moreover, it is non-combustible and provides good thermal insulation properties, enhancing the overall safety and energy efficiency of the construction. Lastly, fiberglass mat tissue is cost-effective, as it requires minimal maintenance and has a long lifespan, reducing the need for frequent replacements.

- Q: How does the width of fiberglass mat tissue affect its conformability?

- The width of fiberglass mat tissue does not directly affect its conformability. Conformability is primarily determined by the flexibility and pliability of the material itself, rather than its width.

- Q: Is fiberglass mat tissue compatible with different types of resins?

- Yes, fiberglass mat tissue is compatible with different types of resins. It is commonly used in the construction industry as a reinforcement material for various resin systems, including polyester, epoxy, and vinyl ester resins. The compatibility of fiberglass mat tissue with different resins makes it versatile and suitable for a wide range of applications.

Send your message to us

Heat Insulation Aluminum Foil Facing glass wool,aluminum foil insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords