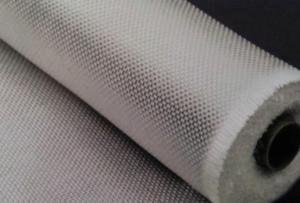

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 800g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

E-glass woven roving Fabric is bidirectional fabric made by 4.5 microns to 17 microns of E-Glass fiber,its high strength ,high modulus ,acid and alkali resistance , high temperature resistance and other properties. often used in protection ,heat insulation ,thermal insulation ,support field . After surface treatment ,it can be made into perfect composite materials . now it is widely used in hand lay up and robot processes to manufacture boats ,vessels ,plane and automotive parts , furniture and sports facilities.

Specifications:

PRODUCT CODE | WOVEN WEIGHT (OZ/YD) | WOVEN WEIGHT (GSM) | STANDARD WIDTH (INCHES) | ROLL LENGTH (M) | THICKNESS (MM) | LOI % | Moisture Content (%) |

CT-PWR24 | 0.86 | 24 | 50 | 50M | 0.04 | ≤0.80 | ≤0.20 |

CT-PWR48 | 1.71 | 48 | 50 | 50M | 0.06 | ≤0.80 | ≤0.20 |

CT-PWR100 | 2.95 | 100 | 50 | 50M | 0.11 | ≤0.80 | ≤0.20 |

CT-PWR135 | 3.99 | 138 | 50 | 50M | 0.14 | ≤0.80 | ≤0.20 |

CT-PWR200 | 5.9 | 200 | 50 | 50M | 0.18 | ≤0.80 | ≤0.20 |

CT-PWR290 | 8.56 | 290 | 50 | 50M | 0.23 | ≤0.80 | ≤0.20 |

Main features:

1.warp and weft rovings aligned in a parallel,flat manner and uniform tension.

2.densely aligned fiber,providing high dimensional stablity and easy handing.

3.good moldability,fast and complete resin wet-out ,enabling high productivity

4.good transparency and high strength of the composite products

Remark:Woven rovings are available in the width range of 50-3000mm and the weight range of 200-1600g/m2

Packaging:

It’s wound into a paper tube( inside diameter about 90mm, outside diameter about 265mm).the mat roll is wrapped with plastic film,and then packed into cardboard box or wrapped with paper.the rolls can be stacked horizontally.the rolls can be palletized or loaded into container.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Is fiberglass mat tissue easy to install?

- Installing fiberglass mat tissue is relatively easy. This lightweight and flexible material can be easily cut and shaped to fit any surface. It can be applied using different methods, including spraying, rolling, or brushing on adhesive. Moreover, the tissue is self-adhesive, which simplifies the installation process as it readily adheres to the desired surface. Additionally, fiberglass mat tissues are generally designed to resist water and offer excellent insulation, making them a favored choice for various applications. In conclusion, by adequately preparing and following the manufacturer's guidelines, installing fiberglass mat tissue can be a simple and trouble-free task.

- Q: Can fiberglass mat tissue be used for pipe insulation?

- Yes, fiberglass mat tissue can be used for pipe insulation. It provides thermal insulation and can help prevent heat loss or gain in pipes. Additionally, it offers excellent resistance to moisture and corrosion, making it suitable for various pipe insulation applications.

- Q: Can fiberglass mat tissue be used for aerospace applications?

- Yes, fiberglass mat tissue can be used for aerospace applications. It is commonly used as a reinforcing material in the aerospace industry due to its excellent mechanical properties, such as high strength-to-weight ratio and resistance to corrosion. Additionally, fiberglass mat tissue can provide thermal insulation and fire resistance, making it suitable for various aerospace components, including aircraft interiors, panels, and structural parts.

- Q: Is fiberglass mat tissue suitable for insulation in high-rise buildings?

- Yes, fiberglass mat tissue is suitable for insulation in high-rise buildings. Fiberglass mat tissue is a widely used insulation material that offers excellent thermal and acoustic properties. It is lightweight, flexible, and easy to install, making it ideal for use in high-rise buildings where efficiency and effectiveness are crucial. Fiberglass mat tissue also has excellent fire-resistant properties, which is an essential requirement for buildings with multiple floors. Additionally, it is resistant to moisture, mold, and pests, ensuring long-term durability and performance. The material can be easily customized to fit various areas of the building, including walls, floors, and ceilings, providing consistent insulation throughout the structure. Overall, fiberglass mat tissue is a reliable and cost-effective insulation option for high-rise buildings.

- Q: Can fiberglass mat tissue be used for repairing fiberglass boats?

- Yes, fiberglass mat tissue can be used for repairing fiberglass boats. Fiberglass mat tissue is a versatile material that is commonly used in repairing and reinforcing fiberglass structures, including boats. It is designed to provide strength and durability, making it an ideal choice for patching holes, cracks, or damaged areas in fiberglass boat hulls. The mat tissue is typically layered with resin to form a solid and stable repair, ensuring that the boat remains structurally sound. Additionally, fiberglass mat tissue is easy to work with and can be cut to the desired size and shape, making it suitable for various repair applications on fiberglass boats.

- Q: How does fiberglass mat tissue perform in terms of thermal expansion?

- Fiberglass mat tissue generally has a low coefficient of thermal expansion, which means it expands and contracts minimally with changes in temperature. This makes it a suitable material for applications where thermal stability is important.

- Q: Does fiberglass mat tissue require any special precautions during cutting?

- Special precautions are necessary when cutting fiberglass mat tissue. Made up of delicate glass strands, inhaling or touching it can be dangerous. To reduce risks, certain measures should be taken. Firstly, it is important to wear appropriate personal protective equipment (PPE) like gloves, safety glasses, and a dust mask or respirator. These will safeguard your skin, eyes, and respiratory system from harm. Secondly, tools specifically designed for cutting fiberglass, such as a serrated-edge utility knife or scissors, should be used. These tools minimize the release of loose fibers and reduce the risk of injury. Moreover, working in a well-ventilated area or using proper dust extraction systems is crucial to prevent the release of fiberglass particles into the air. This minimizes the risk of inhaling fibers and developing respiratory issues. Lastly, handling cut fiberglass mat tissue with care is essential to avoid accidental contact with bare skin. If contact occurs, washing the affected area immediately with soap and water is recommended. Seeking medical attention may be necessary. By following these precautions, the risks associated with cutting fiberglass mat tissue can be minimized, ensuring a safe working environment.

- Q: Does fiberglass mat tissue provide any acoustic insulation?

- Fiberglass mat tissue does provide some degree of acoustic insulation. Due to its fibrous structure, it can absorb sound waves and reduce their transmission through walls or other surfaces. However, it is important to note that the level of acoustic insulation provided by fiberglass mat tissue may vary depending on various factors such as thickness, density, and the specific application. In some cases, additional layers or thicker materials may be required to achieve optimal acoustic insulation.

- Q: Can fiberglass mat tissue be used for automotive applications?

- Yes, fiberglass mat tissue can be used for automotive applications. Fiberglass mat tissue is a versatile material that is commonly used in the automotive industry for various purposes. It is often used as a reinforcement material in composite parts, such as bumpers, body panels, and interior components. The high strength and lightweight properties of fiberglass mat tissue make it an ideal choice for automotive applications, as it helps to enhance the overall performance and durability of the vehicle. Additionally, fiberglass mat tissue can also provide excellent sound insulation and vibration damping properties, which are crucial for improving the comfort and noise reduction in automobiles. Overall, fiberglass mat tissue is a reliable and widely used material in the automotive industry, contributing to the production of high-quality and efficient vehicles.

- Q: How does fiberglass mat tissue compare to cellulose insulation?

- Fiberglass mat tissue and cellulose insulation differ in terms of material composition and insulation properties. Fiberglass mat tissue is made from fine glass fibers, while cellulose insulation is composed of recycled paper fibers treated with fire-retardant chemicals. Fiberglass mat tissue offers higher R-value, meaning it provides better thermal insulation and energy efficiency. Additionally, it is resistant to moisture and does not promote mold growth. On the other hand, cellulose insulation is more affordable, environmentally friendly, and provides better sound insulation. Ultimately, the choice between the two depends on specific insulation needs, budget, and environmental considerations.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 800g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords