Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving 600g-1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of woven roving Description

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

Woven roving Images

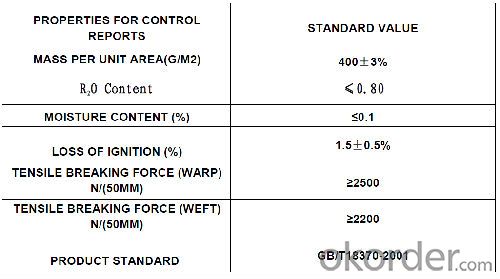

Woven roving Specification:

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: Can fiberglass mat tissue be used for mold making?

- No, fiberglass mat tissue is not typically used for mold making. It is more commonly used in composite manufacturing processes, such as reinforcing fiberglass laminates or repairing damaged fiberglass structures. For mold making, silicone rubber, urethane rubber, or other specialized materials are typically used.

- Q: Is fiberglass mat tissue suitable for insulation in wastewater treatment plants?

- Yes, fiberglass mat tissue is suitable for insulation in wastewater treatment plants. Wastewater treatment plants often require insulation to prevent heat loss, control temperature, and protect against corrosion. Fiberglass mat tissue is a commonly used material for insulation in these facilities due to its high thermal resistance, excellent chemical resistance, and durability. It can effectively insulate pipes, tanks, and other equipment in wastewater treatment plants, ensuring optimal performance and energy efficiency. Additionally, fiberglass mat tissue is lightweight, easy to install, and cost-effective, making it a practical choice for insulation in these harsh environments.

- Q: Is fiberglass mat tissue suitable for wastewater treatment applications?

- Yes, fiberglass mat tissue is suitable for wastewater treatment applications. It is commonly used in the construction of wastewater treatment tanks and pipes due to its corrosion resistance, durability, and ability to withstand harsh chemical environments. Additionally, fiberglass mat tissue is non-reactive to biological and chemical elements present in wastewater, making it an ideal material for such applications.

- Q: Can fiberglass mat tissue be used for reinforcing fiberglass tanks?

- Certainly, fiberglass tanks can be reinforced using fiberglass mat tissue. Fiberglass mat tissue, a lightweight and thin material, is commonly utilized in the construction of fiberglass products. Its purpose is to fortify the fiberglass structure, offering added durability and strength. In the specific case of fiberglass tanks, the mat tissue serves as a layer of reinforcement, further enhancing the tank's overall structural integrity. This reinforcement assists in preventing cracks, improving impact resistance, and augmenting the tank's ability to withstand external forces and pressure. Moreover, fiberglass mat tissue boasts ease of use, enabling simple molding or application onto the tank's surface, thus rendering it a suitable choice for tank reinforcement.

- Q: Does fiberglass mat tissue provide any UV resistance?

- Yes, fiberglass mat tissue typically provides some level of UV resistance. The fiberglass mat tissue is made up of glass fibers that are embedded in a matrix of resin. These fibers and resin provide some degree of protection against UV radiation from the sun. However, it is important to note that the level of UV resistance may vary depending on the specific composition and manufacturing process of the fiberglass mat tissue. Additionally, prolonged exposure to UV radiation can still cause some degradation over time, so it is recommended to take appropriate measures such as using UV-resistant coatings or finishes to enhance the durability and lifespan of the fiberglass mat tissue in outdoor applications.

- Q: Can fiberglass mat tissue be used for making furniture?

- No, fiberglass mat tissue is not suitable for making furniture. It is primarily used in composite materials and construction applications, not for furniture manufacturing.

- Q: Is fiberglass mat tissue suitable for aerospace applications?

- Yes, fiberglass mat tissue is suitable for aerospace applications. Fiberglass mat tissue is a lightweight material that exhibits excellent strength and durability, making it ideal for use in aerospace applications where weight reduction and structural integrity are critical. It is commonly used as a reinforcement material in composite structures and aerospace components such as wings, fuselages, and engine components. Fiberglass mat tissue provides high impact resistance, good thermal stability, and low moisture absorption, which are essential properties for withstanding the harsh conditions and extreme temperatures experienced in aerospace environments. Additionally, fiberglass mat tissue offers good electrical insulation properties, making it suitable for applications that require effective electrical shielding. Overall, fiberglass mat tissue is a reliable and widely used material in the aerospace industry due to its exceptional mechanical properties, lightweight nature, and ability to withstand the demanding conditions of aerospace applications.

- Q: Is fiberglass mat tissue compatible with different adhesives?

- Yes, fiberglass mat tissue is compatible with different adhesives. Fiberglass mat tissue is a versatile material that can be used in various applications such as construction, automotive, and aerospace industries. It is commonly used as a reinforcement material in composites, where it is combined with resin and adhesive to create strong and durable structures. The compatibility of fiberglass mat tissue with different adhesives depends on several factors such as the type of adhesive, the specific application, and the desired performance requirements. Fiberglass mat tissue can be compatible with a wide range of adhesives including epoxy, polyester, vinyl ester, and polyurethane adhesives. It is important to consider the specific properties and characteristics of the adhesive and the fiberglass mat tissue when selecting the adhesive for a particular application. Factors such as curing time, viscosity, bond strength, and chemical resistance should be taken into account to ensure optimal adhesion and performance. In some cases, surface treatment or priming may be necessary to enhance the compatibility between the fiberglass mat tissue and the adhesive. This can involve applying a primer or using a specific surface treatment method to promote adhesion and ensure a strong bond between the two materials. Overall, fiberglass mat tissue is compatible with different adhesives, but it is crucial to consider the specific requirements of the application and select the appropriate adhesive and surface treatment method to achieve the desired results.

- Q: Is fiberglass mat tissue suitable for insulation in residential buildings?

- Yes, fiberglass mat tissue is suitable for insulation in residential buildings. Fiberglass mat tissue is a type of insulation material that is made from glass fibers and is commonly used in residential buildings due to its excellent thermal properties. It has a high R-value, which means it provides effective insulation by reducing heat transfer, keeping the interior of the building warm during winter and cool during summer. Fiberglass mat tissue is also known for its durability and long lifespan, making it a reliable choice for residential insulation. It is resistant to moisture, mold, and pests, ensuring a healthy and comfortable living environment. Additionally, fiberglass mat tissue is lightweight and easy to install, making the insulation process efficient and cost-effective. Furthermore, fiberglass mat tissue is fire-resistant, which is an essential feature for residential buildings. It acts as a barrier, preventing the spread of fire and protecting the occupants and property from potential hazards. Overall, fiberglass mat tissue is a suitable and popular choice for insulation in residential buildings due to its thermal efficiency, durability, fire-resistant properties, and ease of installation.

- Q: Can fiberglass mat tissue be used for making insulation panels?

- Yes, fiberglass mat tissue can be used for making insulation panels. It is a commonly used material due to its excellent thermal insulation properties and its ability to resist heat and cold. Additionally, fiberglass mat tissue is lightweight, durable, and can be easily molded into various shapes and sizes, making it suitable for insulation panel production.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving 600g-1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords