Glass Wool Batts, Glass Wool Blanket Suppliers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

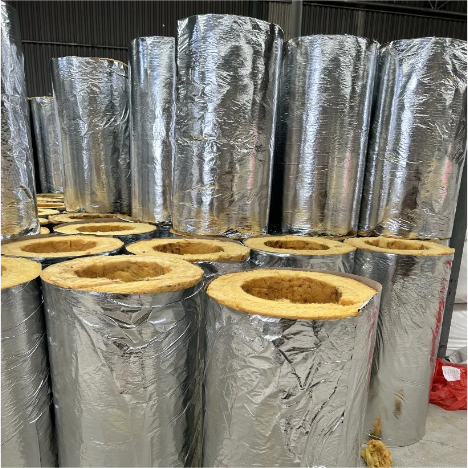

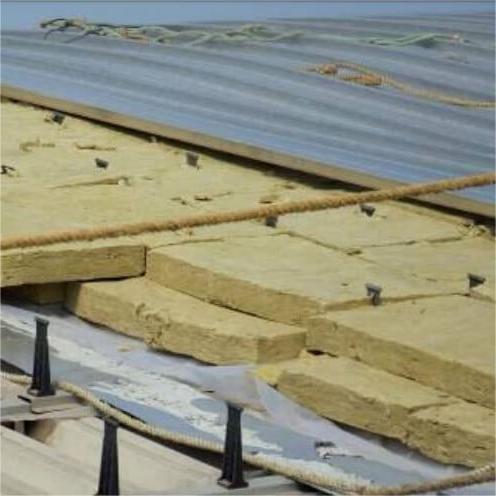

Glass wool, which is made from achromatism plate glass and quartz sand, is inorganic heat preservation material. It is a kind of green building material. What’s more, the scrap can be recycled and be reused. It can meet requirement of environmental protection. It belongs to upmost fire resistance grade, Class A. It totally meet fire proofing requirement of national standard. It can guarantee the safety of building.

Main features:

• Unique technology; rebound degree after compressive packing is up to 99.2%.

• Soft and long glass fibers can maximally lessen flying catkins in the construction.

• Sound absorption and noise reduction; it can effectively prevent sound from spreading.

• Grade A1 incombustible materials.

Applications:

Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

Installation:

FAQ:

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutelyput an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How does fiberglass mat tissue compare to other insulation materials?

- Fiberglass mat tissue, as an insulation material, offers numerous advantages over its counterparts. Primarily, it possesses exceptional thermal insulation properties, effectively preventing the transfer of heat and maintaining indoor temperatures at a comfortable level. This quality is particularly significant in extreme climates, where the building envelope may be susceptible to extreme cold or heat. Furthermore, fiberglass mat tissue exhibits resistance to moisture, mold, and mildew, which contributes to its longevity and durability as an insulation option. Its inability to absorb water prevents the growth of mold and the deterioration of the material over time. This attribute proves especially advantageous in areas with high humidity or a propensity for moisture accumulation, such as basements or bathrooms. In addition, fiberglass mat tissue is non-combustible and possesses a high fire resistance rating. Consequently, it serves as a safe choice for insulation, limiting the spread of flames in the event of a fire. It also acts as a barrier, impeding the fire from extending to other sections of the building and granting occupants valuable time for evacuation. Regarding installation, fiberglass mat tissue is relatively easy to handle and install. It can be conveniently cut to fit any desired shape or size, allowing for flexibility during the installation process. Its versatility is further evident in its applicability to walls, floors, ceilings, and roofs. Lastly, fiberglass mat tissue stands as an environmentally friendly option. It is manufactured from recycled glass and sand, reducing waste and conserving precious natural resources. Moreover, it remains recyclable at the conclusion of its lifespan, further minimizing its environmental impact. Overall, the exceptional thermal insulation properties, durability, moisture and fire resistance, ease of installation, and environmental sustainability of fiberglass mat tissue position it as a highly favorable choice in comparison to alternative insulation materials.

- Q: Can fiberglass mat tissue be used for acoustic insulation?

- Yes, fiberglass mat tissue can be used for acoustic insulation. Fiberglass mat tissue is a lightweight material that has excellent sound absorption properties. It can effectively absorb and dampen sound waves, reducing noise and improving the acoustic environment. Fiberglass mat tissue is commonly used in the construction industry for insulating walls, ceilings, and floors to reduce noise transmission. It is also used in automotive applications and other industries where sound insulation is required. Its high porosity and fibrous structure make it an ideal material for absorbing and attenuating sound waves, making it suitable for acoustic insulation.

- Q: How thick is fiberglass mat tissue typically?

- Fiberglass mat tissue, also known as fiberglass mat or simply mat, typically comes in various thicknesses depending on its intended use. The thickness can range from 0.5 millimeters (mm) to as thick as 3 mm. However, the most commonly used thicknesses for fiberglass mat tissue are 1.5 mm and 2 mm. These thicknesses are ideal for applications such as reinforcing laminates, composite materials, and providing surface finishes. It is important to note that the specific thickness of fiberglass mat tissue may vary depending on the manufacturer and the specific requirements of the project.

- Q: Does fiberglass mat tissue require any special maintenance after installation?

- Once the fiberglass mat tissue is installed, it typically requires no special maintenance. Its design makes it durable and resistant to wear and tear, as well as highly resistant to moisture, chemicals, and UV radiation. This versatility makes it suitable for a variety of applications, such as roofing, insulation, and wall covering. However, it is advisable to periodically inspect the fiberglass mat tissue to guarantee its good condition. This involves checking for any indications of damage, such as cracks, tears, or delamination. In the event of any issues, prompt attention should be given to prevent further harm. Furthermore, it is essential to adhere to the manufacturer's guidelines and recommendations concerning the specific type of fiberglass mat tissue used. This may involve avoiding exposure to certain chemicals or utilizing appropriate cleaning methods if necessary. In summary, while fiberglass mat tissue generally requires minimal upkeep, regular inspections and adherence to the manufacturer's instructions can promote its durability and optimal functionality.

- Q: What are the properties of fiberglass mat tissue?

- Fiberglass mat tissue possesses several key properties that make it highly versatile and widely used in various industries. Firstly, it is lightweight, which enables easy handling and installation. It is also flexible, allowing it to conform to various shapes and contours. Additionally, fiberglass mat tissue is highly durable and possesses excellent tensile strength, making it resistant to tearing or breaking. It is also resistant to corrosion, moisture, and chemicals, making it suitable for applications in harsh environments. Lastly, it has excellent thermal and electrical insulation properties, making it an ideal choice for applications requiring heat or electrical resistance.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The adhesion of resin to fiberglass mat tissue can be significantly influenced by its surface finish. The surface finish pertains to the texture or smoothness of the fiberglass mat tissue. In general, a rough surface finish tends to promote better adhesion to resin. This is because a rough surface provides a larger area for the resin to adhere to, resulting in a stronger bond. Rough surface finishes can be achieved through different manufacturing techniques, such as using coarser fibers or incorporating texturizing agents during production. On the contrary, a smoother surface finish may lead to weaker adhesion. A smooth surface does not offer as much area for the resin to bond with, resulting in a weaker and less durable bond. Smoother surface finishes can be attained by using finer fibers or through additional processing steps to smoothen the surface. When selecting the surface finish of fiberglass mat tissue, it is crucial to consider the specific application and requirements. For applications that necessitate high strength and durability, a rougher surface finish may be preferable to ensure optimal adhesion to the resin. Conversely, for applications where a weaker bond is acceptable or where a smoother surface finish is desired for aesthetic reasons, a smoother surface finish may be chosen. Ultimately, the surface finish of fiberglass mat tissue plays a vital role in determining the adhesion to resin. It is essential to choose the appropriate surface finish to achieve the desired strength, durability, and performance in various applications.

- Q: Can fiberglass mat tissue be used for making surfboards?

- Surfboards can indeed be made using fiberglass mat tissue. This material, known for its lightweight yet robust properties, is commonly utilized in constructing surfboards. Typically, it is combined with epoxy resin to form a sturdy and durable surface. By incorporating fiberglass mat tissue, surfboards gain the strength and flexibility necessary to endure the demanding conditions encountered while riding waves. Moreover, the smooth and sleek texture of the material enhances the surfboard's performance and speed. In summary, fiberglass mat tissue is a favored option for constructing high-performance surfboards due to its exceptional strength-to-weight ratio.

- Q: What is the chemical resistance of fiberglass mat tissue?

- Fiberglass mat tissue has excellent chemical resistance due to its composition, which includes a high percentage of glass fibers. These fibers provide a barrier against various chemicals, making the fiberglass mat tissue highly resistant to corrosion and degradation when exposed to acids, alkalis, solvents, and other harsh chemicals.

- Q: Is fiberglass mat tissue resistant to chemicals?

- Yes, fiberglass mat tissue is generally resistant to chemicals. The composition of fiberglass mat tissue, which consists of fine glass fibers bonded together with a resin, provides it with excellent chemical resistance properties. This resistance allows the fiberglass mat tissue to withstand exposure to a wide range of chemicals without deteriorating or losing its structural integrity. However, it is important to note that the specific chemical resistance of fiberglass mat tissue may vary depending on the type and concentration of the chemical it comes into contact with. Therefore, it is always advisable to consult the manufacturer's guidelines or conduct appropriate testing to ensure compatibility with specific chemicals.

- Q: What is the abrasion resistance of fiberglass mat tissue?

- The abrasion resistance of fiberglass mat tissue is high, making it suitable for applications that require durability and resistance to wear and tear.

Send your message to us

Glass Wool Batts, Glass Wool Blanket Suppliers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords