Fiberglass Mat Tissue - E-Glass Fiberglass Woven Roving, 400g, 1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

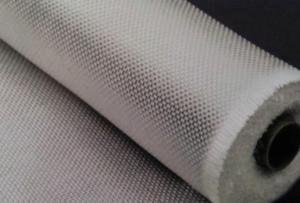

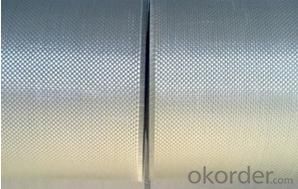

Structure of woven roving Description

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

Woven roving Images

Woven roving Specification: weight& thickness

Normal type | EWR800-1000 | Test Standard |

Apperance | Good | GB/T 18370-2001 |

Density(warpxweft)(end/cm) | 1.8 X 1.5 | GB/T 7689.2-2001 |

Tex (warpxweft) | 2400x2400 | ISO1889 |

Moisture content(%) | ≤0.10 | ISO3344 |

Loss on ignition(%) | 0.40-0.80 | ISO1887 |

Glass | E-glass | N/A |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: What is the impact resistance of fiberglass mat tissue at high temperatures?

- The impact resistance of fiberglass mat tissue at high temperatures is generally quite good. The fiberglass material offers excellent strength and durability, allowing it to maintain its structural integrity even when exposed to elevated temperatures. However, it is important to note that the specific impact resistance can vary depending on factors such as the thickness and composition of the fiberglass mat tissue. Overall, fiberglass mat tissue is known for its ability to withstand impacts and maintain its performance even under high temperature conditions.

- Q: Can fiberglass mat tissue be used for bridge deck rehabilitation?

- Indeed, bridge deck rehabilitation can utilize fiberglass mat tissue. Known for its exceptional strength and durability, this versatile material is commonly employed in construction endeavors, including the restoration of bridge decks. Its primary function is to reinforce and fortify existing structures. Bridge deck rehabilitation encompasses the process of rectifying and rejuvenating a bridge deck that has undergone deterioration over time. Typically, this procedure necessitates the removal of damaged concrete, the application of a fresh concrete layer, and the reinforcement of said layer with materials like fiberglass mat tissue. The utilization of fiberglass mat tissue as a reinforcement material in bridge deck rehabilitation is widespread due to its exceptional mechanical properties. Its high tensile strength plays a vital role in augmenting the load-bearing capacity of the bridge deck. Moreover, its corrosion resistance is especially crucial for bridge decks exposed to harsh weather conditions and chemicals. Additionally, fiberglass mat tissue is easily installed and adaptable to bridge decks of varying shapes and sizes. It can be embedded into the new concrete layer during the construction process or applied as an overlay onto the existing deck. This flexibility renders it an ideal choice for bridge deck rehabilitation projects. In conclusion, fiberglass mat tissue is, indeed, an appropriate material for bridge deck rehabilitation. Its robustness, endurance, and corrosion resistance make it an effective reinforcement material for repairing and fortifying bridge decks. Furthermore, its straightforward installation process and versatility further enhance its suitability for this specific application.

- Q: What is the typical thickness of fiberglass mat tissue?

- The typical thickness of fiberglass mat tissue can vary depending on the specific application and intended use. However, it is commonly available in thicknesses ranging from 0.5mm to 3mm. The choice of thickness is determined by factors such as the desired strength, flexibility, and absorption properties required for the particular project or product being manufactured. Thicker fiberglass mat tissue is generally used for applications that require higher levels of strength and durability, while thinner tissue is suitable for more lightweight and flexible applications.

- Q: How is fiberglass mat tissue used in the production of printed circuit boards?

- Fiberglass mat tissue is commonly used in the production of printed circuit boards (PCBs) as a reinforcement material. PCBs are typically made of layers of copper, insulating materials, and fiberglass. The fiberglass mat tissue serves as a structural support and helps provide mechanical strength to the PCB. During the manufacturing process, the fiberglass mat tissue is impregnated with a resin, usually epoxy, to form a laminate material. This laminate is then layered with copper foils, which act as conductive pathways for the electrical signals on the PCB. The fiberglass mat tissue plays a crucial role in the PCB's performance and reliability. It provides a solid foundation for the copper layers, preventing them from delaminating or warping due to mechanical stress or temperature changes. It also helps to maintain the dimensional stability of the PCB, ensuring that it remains flat and rigid. Furthermore, the fiberglass mat tissue enhances the PCB's resistance to heat and moisture. The epoxy resin used in the laminate offers excellent insulation properties, protecting the copper conductors from short circuits or electrical leakage. Additionally, the fiberglass mat tissue acts as a barrier against moisture absorption, preventing the PCB from becoming damaged or malfunctioning. In summary, fiberglass mat tissue is an essential component in the production of printed circuit boards. It provides structural support, enhances mechanical strength, ensures dimensional stability, and improves resistance to heat and moisture. Ultimately, the use of fiberglass mat tissue contributes to the overall reliability and performance of PCBs in various electronic devices.

- Q: Does fiberglass mat tissue provide any UV resistance?

- Indeed, some degree of UV resistance is typically offered by fiberglass mat tissue. Comprised of glass fibers embedded in a resin matrix, this material provides a certain level of safeguard against UV radiation emitted by the sun. Nevertheless, it should be emphasized that the extent of UV resistance may differ based on the precise composition and manufacturing procedure of the fiberglass mat tissue. Furthermore, extended exposure to UV radiation can still result in gradual deterioration. Therefore, it is advisable to implement suitable measures, such as employing UV-resistant coatings or finishes, to augment the longevity and resilience of fiberglass mat tissue when utilized outdoors.

- Q: Can fiberglass mat tissue be used for insulation in commercial buildings?

- Insulation in commercial buildings can be achieved using fiberglass mat tissue. This material is commonly utilized due to its exceptional thermal performance, durability, and cost-effectiveness. Typically composed of fine glass fibers bonded with resin, the mat can be applied to various surfaces such as walls and ceilings to enhance energy efficiency by minimizing heat transfer. Proper insulation is vital in commercial buildings to maintain a comfortable indoor environment and reduce energy usage. Fiberglass mat tissue offers numerous benefits for insulation purposes. It possesses low thermal conductivity, effectively resisting heat flow and diminishing heat loss or gain through the building envelope. This results in lower energy expenses and improved temperature control. Furthermore, fiberglass mat tissue is lightweight and easy to install, making it a convenient option for commercial buildings. It can be easily cut and shaped to fit around obstacles, ensuring a secure seal and preventing air leakage. This further enhances the effectiveness of the insulation. Moreover, fiberglass mat tissue is non-combustible, providing an added safety advantage in commercial buildings where fire protection is paramount. It does not contribute to the spread of flames and its fire resistance properties assist in containing fires and offering valuable escape time during emergencies. Overall, fiberglass mat tissue is a suitable and widely utilized insulation material in commercial buildings. Its thermal performance, ease of installation, and fire resistance make it a dependable choice for achieving energy efficiency and comfort in commercial spaces.

- Q: What are the typical mechanical properties of fiberglass mat tissue?

- Fiberglass mat tissue possesses high tensile strength, stiffness, and dimensional stability, which are its typical mechanical properties. It is recognized for its remarkable ability to resist breakage and deformation when subjected to stress, making it suitable for applications that necessitate durability and structural integrity. Furthermore, it demonstrates good impact resistance, enabling it to endure external forces without substantial harm. Moreover, fiberglass mat tissue exhibits a low coefficient of thermal expansion, indicating that it is less susceptible to expanding or contracting due to temperature changes, resulting in enhanced dimensional stability. These characteristics render fiberglass mat tissue a favored choice in diverse industries like construction, automotive, and aerospace, wherein strength and reliability are pivotal considerations.

- Q: Can fiberglass mat tissue be used for making lightweight automotive parts?

- Fiberglass mat tissue is indeed suitable for creating lightweight automotive parts. This material, known for its versatility, is widely used in the manufacturing process of automotive components. It boasts an impressive strength-to-weight ratio, making it perfect for producing durable and high-performing lightweight parts. Furthermore, the ease with which fiberglass mat tissue can be molded into different shapes allows for intricate and customized automotive designs. Its notable resistance to corrosion, chemicals, and temperature changes only adds to its suitability for automotive applications. In conclusion, fiberglass mat tissue is a dependable and cost-efficient option for crafting lightweight automotive parts.

- Q: Can fiberglass mat tissue be used for insulating refrigeration units?

- Yes, fiberglass mat tissue can be used for insulating refrigeration units. Fiberglass mat tissue is a lightweight material that has excellent thermal insulation properties. It is commonly used in various applications where insulation is required, including refrigeration units. The fiberglass mat tissue helps to reduce heat transfer, keeping the internal temperature of the refrigeration unit stable and preventing any external heat from affecting the stored items. Additionally, fiberglass mat tissue is resistant to moisture, which is important in refrigeration units to prevent condensation and maintain the efficiency of the cooling system. Overall, fiberglass mat tissue is a suitable and effective choice for insulating refrigeration units.

- Q: What are the potential health and safety concerns associated with working with fiberglass mat tissue?

- Working with fiberglass mat tissue can pose several potential health and safety concerns. Firstly, fiberglass contains tiny glass fibers that can become airborne when the material is cut, sanded, or disturbed. Inhalation of these fibers can lead to respiratory problems such as coughing, wheezing, and difficulty breathing. Prolonged exposure to fiberglass dust may also cause lung diseases like fibrosis or even lung cancer. Additionally, direct contact with fiberglass mat tissue can irritate the skin, leading to itching, redness, and rashes. The sharp edges of the glass fibers can cause tiny cuts or punctures, which may become infected if not properly treated. Moreover, fiberglass is a lightweight material that can easily become airborne and settle on surfaces, increasing the risk of ingestion or contamination of food and drinks. Ingesting fiberglass particles can irritate the digestive system, causing nausea, vomiting, and abdominal pain. To ensure the health and safety of workers, proper precautions should be taken when working with fiberglass mat tissue. This includes wearing personal protective equipment such as gloves, safety glasses, and respiratory masks to minimize exposure to airborne fibers. Adequate ventilation and dust control measures should also be in place to prevent the accumulation of fiberglass dust in the work area. Regular cleaning and maintenance should be performed to keep the work environment free from fiberglass particles. Workers should be educated on the proper handling and disposal of fiberglass materials to minimize the risk of contamination. Overall, while fiberglass mat tissue is a widely used material, it is important to be aware of the potential health and safety concerns associated with its handling and take necessary precautions to minimize the risk of exposure.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiberglass Woven Roving, 400g, 1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords