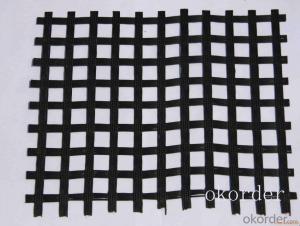

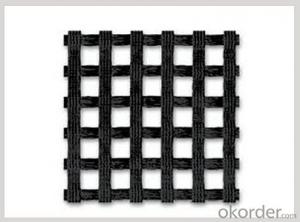

Preis Geotextil Fiberglass High Modulus Geogrid Polyethylene for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

We offer a unique line of extruded polymer grids for protecting and reinforcing grassed vehicular areas. Reinforcement Mesh is a tough extruded polymer grid for reinforcing grassed areas used by vehicles and pedestrians. We are inert to biological degradation and resistant to creep, strain and naturally found chemicals.steel-plastic composite geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Production function

1.It can be applied in all kinds of roads,airports to enhance the roadbed;

2.It can be applied in a large car park and terminal freight yard,etc. to strengthen the foundations of a permanent load;

3.It can be applied in rail, road slope's protection;

4.It can be applied to enhance the culvert;

5.It can be applied as a secondary enhancement after the uniaxial Geogrid soil enhancement, further enhance the soil;

6.It can be applied in mining, tunnel reinforcement.

7.Network used for animal and husbandry;

8.Network used for cage fishing.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Production of 1 square meter 100g geotextile consumption of polyester fiber how many kilograms

- Of course, or 100 grams of Kazakhstan, the loss can be ignored manufacturers do not produce geotextile geomembrane

- Q: Do you have a drainage board and geotextile on the roof

- Good, but you use very little, the purchase is difficult, the price will not be cheap Huazhi geotextile material manufacturers

- Q: How do geotextiles improve the performance of coastal structures?

- Geotextiles improve the performance of coastal structures by providing erosion control, stabilizing the soil, and enhancing drainage. They act as a barrier to prevent soil erosion, reducing the likelihood of structural damage caused by waves, tides, and storm surges. Geotextiles also help stabilize the soil by increasing its shear strength, preventing the movement and settling of the structure. Additionally, they enhance drainage by allowing water to pass through while retaining the soil particles, preventing clogging and maintaining the structure's stability. Overall, geotextiles play a vital role in increasing the durability and longevity of coastal structures.

- Q: Can geotextiles be used in subsurface drainage applications?

- Yes, geotextiles can be used in subsurface drainage applications. They are often used as a filter or separator in drainage systems to prevent soil particles from clogging the drainage pipes or channels while allowing water to pass through. Geotextiles can enhance the effectiveness and longevity of subsurface drainage systems by preventing soil compaction and maintaining the flow of water.

- Q: Can geotextiles be used in the construction of green roofs?

- Yes, geotextiles can be used in the construction of green roofs. Geotextiles are often used as a layer in green roof systems to provide drainage and filtration, helping to manage water flow and prevent erosion. They can also help to separate different layers of the green roof system and provide stability to the growing medium.

- Q: How do geotextiles help with reinforcement of geotextile bags?

- Geotextiles help with the reinforcement of geotextile bags by providing strength and stability to the bags. They act as a barrier and prevent the soil or other fill material from escaping through the pores of the bags. Additionally, the geotextiles distribute the weight of the fill material evenly, reducing the risk of bulging or bursting of the bags.

- Q: How do geotextiles aid in the reduction of frost heave?

- Geotextiles aid in the reduction of frost heave by providing a barrier that prevents the upward movement of moisture within the soil. This barrier minimizes the formation of ice lenses, which are a major cause of frost heave. Additionally, geotextiles help to distribute the load more evenly across the soil, reducing the pressure on the underlying layers and minimizing the potential for frost heave to occur.

- Q: Will geotextiles generally use where?

- Water conservancy project dam and slope protection of the filter, channel isolation, anti - seepage. ⒉ road, railway, airport runway foundation isolation, filter, drainage, soil slope, retaining wall and road reinforcement, drainage. ⒊ port engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage. ⒋ landfill, thermal power plant ash dam, mine tailings dam isolation, seepage control.

- Q: Does geotextile affect water purification?

- Do not know what you use after the purification of water, if not drinking water, I think it will not affect the water quality, the general purpose of water purification, geotextile will not affect, because the geotextile material is polyester or polypropylene, In the chemical nature of relatively stable, no changes in room temperature conditions, so there will not be any impact on water quality

- Q: Pool with geomembrane but not long enough to stick to the pool side

- Should be geomembrane professional welding machine welding, not long enough, then do not seepage effect, I am specializing in the production of geotextile geomembrane and other materials, wish smooth

Send your message to us

Preis Geotextil Fiberglass High Modulus Geogrid Polyethylene for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords