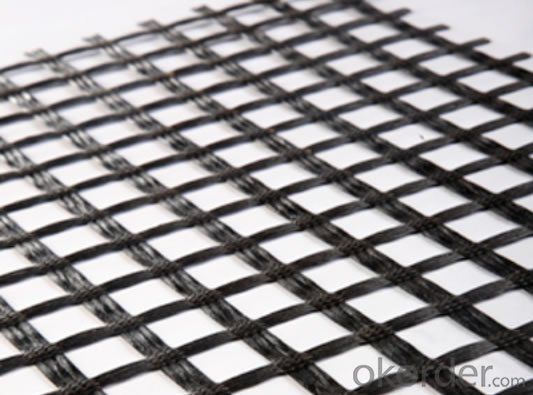

High-Density Polyethylene Geogrids for High Strength Fiberglass Geogrid in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Geogrid is widely used in civil construction over the whole world. It is manufactured on the basis of high-impact polyethylene and polypropylene. Geogrids are used as reinforcement materials on mellow soils for railway and car roads, parking places, landing grounds and for the reinforcement of bridge piers, slopes and earth banks, for erosion protection of slopes.

1)fiberglass geogrid with CE certificate

2)Materials:fiberglass

3) Tensile strength:MD/CD:30 ~ 200kn/m

4)WIdth:1 ~ 6m

Material Major Advantages

Geogrid application is a way of soil reinforcement, On soil surface a plate is created according to the thickness of a corresponding geogrid: 50 mm, 100 mm, 150 mm, 200 mm (this standard range of products is manufactured by “Technostroytex” LLC).

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geogrids be used in shoreline erosion control projects?

- Yes, geogrids can be used in shoreline erosion control projects. Geogrids are often used to stabilize and reinforce soil in coastal areas to prevent erosion and maintain the integrity of shorelines. They can be installed to reinforce slopes, prevent soil movement, and provide structural stability to prevent further erosion.

- Q: Are geogrids resistant to puncture?

- Yes, geogrids are typically resistant to puncture due to their durable construction and materials used. They are designed to withstand various stresses and loads, including sharp objects and heavy loads without getting punctured.

- Q: What are the differences between three different types of geogrids?Unidirectional geogrid, two-way geogrid plastic, geogrid, warp knitted geogrid and fiberglass geogridWhich is the best place in Guangzhou geogrid Zhejiang geogrid in Tianjin?

- Steel plastic geogrid, fiberglass geogrid, polyester geogrid, etc., according to the direction of stress is divided into one-way

- Q: Can geogrids be used in slope stabilization for railway embankments with high water table conditions?

- Yes, geogrids can be used in slope stabilization for railway embankments with high water table conditions. Geogrids are commonly used in such situations to reinforce and stabilize the soil, preventing erosion and maintaining the integrity of the slope. Their high tensile strength and ability to distribute loads make them suitable for railway embankments with high water table conditions.

- Q: Do geogrids affect the permeability of soil?

- Yes, geogrids can affect the permeability of soil. Geogrids are commonly used as reinforcement materials in civil engineering projects to improve the stability and load-bearing capacity of soils. By distributing the applied loads over a larger area, geogrids reduce the pressure on the soil particles, which can minimize soil compaction and increase the void space within the soil. This can enhance the permeability of the soil, allowing water to flow more freely through it. Therefore, geogrids can have a positive impact on the permeability of soil.

- Q: Can geogrids be used in reinforced concrete structures?

- Yes, geogrids can be used in reinforced concrete structures. Geogrids are commonly used as a reinforcement material in soil and pavement applications, but they can also be integrated into concrete structures to enhance their strength, stability, and durability. By incorporating geogrids in concrete, it is possible to reduce cracking, increase load-bearing capacity, and improve overall performance of the structure.

- Q: How do geogrids improve the performance of mechanically stabilized slopes during seismic events?

- Geogrids improve the performance of mechanically stabilized slopes during seismic events by providing additional reinforcement and enhancing the stability of the slopes. They act as a tension element, distributing and transferring the seismic forces throughout the slope, thereby reducing the potential for slope failure and displacement. Geogrids also increase the strength and stiffness of the soil, improving its resistance to shear and lateral movement caused by seismic shaking. Overall, geogrids enhance the structural integrity of mechanically stabilized slopes, making them more resistant to seismic events.

- Q: How do geogrids improve the performance of geocomposites?

- Geogrids improve the performance of geocomposites by adding tensile strength and stabilization to the overall structure. They enhance the load-bearing capacity and reduce deformation, effectively reinforcing the geocomposite system.

- Q: Can geogrids be used in reinforced earth walls?

- Yes, geogrids can be used in reinforced earth walls. Geogrids are commonly used as reinforcement elements in reinforced earth walls to improve stability and increase load-bearing capacity. They provide tensile strength and distribute loads, preventing soil movement and enhancing the overall performance of the structure.

- Q: Where can I do three to the geogrid test?

- Currently did not find the corresponding three geogrid test specification, how to determine the direction of the three cells, how to load are not standardized

Send your message to us

High-Density Polyethylene Geogrids for High Strength Fiberglass Geogrid in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords