FRP Roofing Panel - Fibreglass Reinforced Polyester (FRP) Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fibreglass / Fiberglass Reinforced Plastic (FRP) or Glass Fiber Reinforced Plastic (GRP) is composed of thermosetting plastics and reinforced fiberglass, Greater than that of steel products and aluminum products in specific tenacity. Products in the ultra-low temperature or high temperature will not happen brittle fracture, deformation and to prevent heat transfer. Corrosion products in the environment anti-aging, yellowing resistance, corrosion resistance, friction resistance, easy to clean. Can be instead of aluminum, stainless steel plates, tiles and so on.

FEATURES

Corrosion resistance,last 10-15 years life span

Color stable.

Sound absorption and heat insulation.

Good water resistance.

Fireproof resistance.

Easy to install.

Good impact and low temperature resistance.

Light weight.

Stable volume.

SPECIFICATIONS

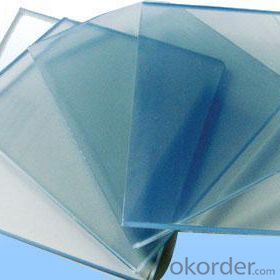

| Name: | Fibreglass Reinforced Polyester(FRP ) Sheet |

| Material: | Protective film, Unsaturated resin polyester, Fiberglass |

| Weight: | 1800g/2400g/2750g/3050g Square meter |

| Thickness: | 0.8~3.0mm |

| Length: | Customized |

| Temp: | used in -40°c to 140 °c |

| OEM: | Welcomed |

| Color: | Clear/Blue |

PICTURES

- Q: Are FRP roofing panels available in different thicknesses?

- FRP roofing panels can be found in various thicknesses, allowing for customization based on project or application needs. The thickness of these panels varies between 0.8mm and 3mm, with the possibility of thicker options for specific purposes. The decision on thickness often relies on factors like desired durability, insulation properties, and load-bearing capacity. It is crucial to seek guidance from professionals or suppliers to identify the ideal thickness for your FRP roofing panel requirements.

- Q: Can FRP roofing panels be used for both residential and commercial green walls?

- Yes, FRP roofing panels can be used for both residential and commercial green walls. The durable and lightweight nature of FRP panels makes them suitable for vertical gardens and green walls in various settings. Their resistance to moisture, UV rays, and chemicals ensures long-lasting performance in both residential and commercial applications.

- Q: Can FRP roofing panels be used for parking structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for parking structures. FRP panels are known for their durability, lightweight nature, and resistance to corrosion, making them suitable for various applications, including parking structures. They offer excellent protection against weather elements, are easy to install and maintain, and can provide sufficient natural lighting. Additionally, FRP panels can be customized to meet specific design requirements, making them a versatile choice for parking structures.

- Q: Are FRP roofing panels suitable for both residential and commercial buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for both residential and commercial buildings. FRP panels offer a range of benefits that make them an excellent choice for roofing applications in both types of structures. Firstly, FRP panels are lightweight yet incredibly strong, making them suitable for use in various building types. Whether it's a small residential home or a large commercial building, FRP panels can provide reliable and durable roofing solutions. Additionally, FRP panels are highly resistant to corrosion, UV rays, and weathering. This makes them particularly suitable for both residential and commercial buildings, as they can withstand the elements and maintain their structural integrity over time. Whether it's exposure to harsh weather conditions or the need for long-term durability, FRP roofing panels are up to the task. Furthermore, FRP panels are versatile and can be customized to meet the specific requirements of residential and commercial buildings. They are available in various sizes, colors, and designs, allowing for flexibility in architectural aesthetics. Additionally, FRP panels can be easily installed, reducing the time and cost associated with roofing projects. In terms of energy efficiency, FRP panels can contribute to reducing energy consumption in both residential and commercial buildings. Their insulation properties help regulate temperature, reducing the need for excessive heating or cooling. This can result in energy savings and improved comfort levels for occupants. Overall, FRP roofing panels are a suitable choice for both residential and commercial buildings. Their lightweight yet strong nature, resistance to corrosion and weathering, versatility, and energy efficiency properties make them an excellent option for various roofing applications.

- Q: Can FRP roofing panels be installed on steel structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on steel structures. FRP panels are a versatile roofing material that can be used on various types of structures, including steel buildings. The lightweight nature of FRP panels makes them suitable for installation on steel structures without adding excessive weight to the overall structure. Additionally, FRP panels provide excellent resistance to corrosion, which is beneficial when installing them on steel structures that are susceptible to rusting. Overall, FRP roofing panels can be a durable and cost-effective choice for steel structures.

- Q: Can FRP roofing panels be installed on concrete structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on concrete structures. FRP roofing panels are known for their durability, lightweight nature, and resistance to corrosion, making them suitable for a wide range of applications, including concrete structures. These panels can be easily installed on concrete roofs using various methods, such as mechanical fastening, adhesive bonding, or a combination of both. It is important to ensure that the concrete surface is clean, dry, and free from any debris or loose particles before installation. Additionally, proper sealing and flashing techniques should be employed to prevent any potential water leakage. Overall, FRP roofing panels offer a cost-effective and efficient solution for enhancing the longevity and performance of concrete structures.

- Q: Are FRP roofing panels resistant to warping or bending from heavy snow loads?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to warping or bending from heavy snow loads. FRP panels are known for their high strength and durability, which enable them to withstand various weather conditions, including heavy snow. The fiberglass reinforcement in FRP panels provides added structural integrity, reducing the risk of warping or bending under significant snow loads. However, it is important to note that the actual resistance to warping or bending can vary depending on factors such as the specific design and installation of the FRP roofing system, the thickness and quality of the panels, and the amount of snow accumulation. Therefore, it is advisable to consult with a professional engineer or contractor to ensure that the FRP roofing panels are suitable for the specific snow load requirements of your location.

- Q: Are FRP roofing panels noisy during rain or hailstorms?

- FRP (Fiberglass Reinforced Plastic) roofing panels are designed to be durable and provide excellent protection against various weather conditions, including rain and hailstorms. When it comes to noise, FRP panels generally produce less noise compared to other roofing materials such as metal or asphalt. During rainstorms, FRP roofing panels tend to absorb and dampen the sound of raindrops, resulting in a quieter indoor environment. The fiberglass composition of the panels helps to reduce the impact noise and minimize the reverberation of rain hitting the surface. This can be particularly beneficial for those who prefer a peaceful and tranquil living or working space. In terms of hailstorms, FRP panels can also reduce the noise caused by hailstones hitting the roof. The fiberglass material absorbs some of the impact energy, thereby reducing the intensity of the sound. However, it's important to note that extremely large hailstones may still produce noticeable noise, as the impact force could be higher. Nevertheless, FRP roofing panels generally provide a quieter experience during hailstorms compared to other roofing materials. Overall, FRP roofing panels are not typically known for being excessively noisy during rain or hailstorms. The design and composition of these panels help to minimize noise levels, making them a suitable choice for those seeking a quieter roofing solution.

- Q: Can FRP roofing panels be used for storage buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for storage buildings. FRP roofing panels are lightweight, durable, and resistant to various weather conditions, making them suitable for use in storage buildings. They provide excellent protection against UV rays, corrosion, and impact, ensuring that the contents inside the storage building remain safe and secure. Additionally, FRP roofing panels are easy to install, cost-effective, and low maintenance, making them a popular choice for storage buildings.

- Q: Can FRP roofing panels be used for balcony coverings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for balcony coverings. FRP panels are known for their durability, weather resistance, and lightweight properties, making them suitable for various applications including balcony coverings. These panels are designed to withstand harsh environmental conditions, such as UV radiation, extreme temperatures, and moisture, making them an ideal choice for outdoor spaces like balconies. Additionally, FRP panels are available in different colors, finishes, and designs, allowing for customization to match the aesthetic requirements of the balcony. They are also relatively easy to install and maintain, making them a practical choice for covering balconies while providing protection and enhancing the overall appearance of the space.

Send your message to us

FRP Roofing Panel - Fibreglass Reinforced Polyester (FRP) Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords