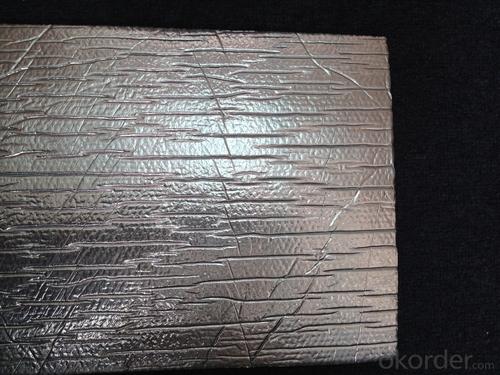

Fiberglass Facing Flexible Ducts Bubble Insulation Green Energy

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: Does fiberglass facing require regular maintenance?

- No, fiberglass facing does not require regular maintenance.

- Q: What are the similarities and differences between white and black fiberglass tissue?

- <p>White and black fiberglass tissues are similar in that they are both made from glass fibers combined with a resin. They share properties such as strength, durability, and resistance to various environmental factors. However, the primary difference lies in their appearance, with white fiberglass tissue being lighter in color and often used for aesthetic purposes or in applications where a lighter color is preferred. Black fiberglass tissue is typically used in applications where color is not a concern or where a darker color is beneficial, such as in some industrial settings. The choice between white and black fiberglass tissue often depends on the specific requirements of the project or product being manufactured.</p>

- Q: What is the chemical stability of black fiberglass tissue, and how does it react to various chemicals?

- <p>Black fiberglass tissue, which is a type of composite material made from glass fibers and a resin matrix, typically exhibits good chemical stability. It is resistant to many chemicals, including alkalis, acids, and salts, making it suitable for various industrial applications. However, it may not be as stable against strong acids or bases over extended periods. The stability can also be influenced by the specific type of resin used in the fiberglass, with some resins offering better resistance to certain chemicals than others. It's important to consult the material data sheet for specific information on chemical resistance for the black fiberglass tissue in question.</p>

- Q: Is it possible to use black fiberglass tissue in the manufacturing of furniture?

- <p>Yes, black fiberglass tissue can be used for furniture manufacturing. It is known for its strength, durability, and resistance to various environmental conditions, making it suitable for creating sturdy and long-lasting furniture. Fiberglass is often used in outdoor furniture and certain types of modern indoor furniture due to its versatility and ability to be molded into various shapes. However, it's important to consider the aesthetic appeal and the specific requirements of the furniture design when choosing to use black fiberglass tissue.</p>

- Q: Is it possible to recycle black fiberglass tissue in landfills?

- <p>Black fiberglass tissue, like other types of fiberglass, is not typically recycled in landfills. Landfills are not designed for recycling, but rather for the disposal of waste. Fiberglass is a composite material that is difficult to recycle due to its complex composition and the presence of resins that can make it challenging to separate the glass fibers from other components. Specialized recycling facilities are required to process fiberglass, and even then, the recycling process can be energy-intensive and costly. Therefore, black fiberglass tissue is usually not recycled in landfills and is instead disposed of as solid waste.</p>

- Q: Is it possible to utilize black fiberglass tissue in construction?

- <p>Yes, black fiberglass tissue can be used as a building material. It is known for its strength, durability, and resistance to various environmental factors, making it suitable for construction purposes. It is often used in the form of reinforced plastic or composite materials, enhancing the structural integrity of buildings and providing insulation. However, it's important to follow specific guidelines and regulations for its use in construction to ensure safety and effectiveness.</p>

- Q: This question is asking about the differences in the quality of black fiberglass tissues based on the brand they are manufactured by.

- <p>The quality of black fiberglass tissues can vary significantly by brand due to differences in manufacturing processes, materials used, and quality control standards. Some brands may use higher quality raw materials, resulting in stronger and more durable tissues. Others might prioritize cost-effectiveness, which could lead to a compromise in quality. Additionally, the weaving techniques and the density of the fibers can affect the strength and flexibility of the tissues. Brand reputation and consumer reviews can also provide insights into the quality and performance of black fiberglass tissues from different manufacturers. It's important for consumers to consider these factors when selecting a brand for their specific needs.</p>

- Q: Is not the multi-layer membrane waterproof, the bottom of the membrane should use glass fiber mats?

- We project two layers of SBS membrane waterproof, is not just use PY on the line

- Q: Can I repurpose old black fiberglass tissues for cleaning purposes?

- <p>Yes, you can use your old black fiberglass tissues to make cleaning cloths or wipes. Fiberglass tissues are durable and can effectively pick up dirt and grime. However, it's important to ensure that the tissues are clean and free from any contaminants before repurposing. Cut them into desired sizes and use them for general cleaning tasks. Be cautious with the edges as fiberglass can be sharp. Always handle with care and consider wearing gloves to avoid irritation or injury.</p>

- Q: This question asks about the proper storage methods for black fiberglass paper.

- <p>To store black fiberglass paper, follow these guidelines: Keep it in a cool, dry place away from direct sunlight and moisture. Ensure the storage area is well-ventilated to prevent the buildup of humidity. Store the paper on flat surfaces to avoid bending or creasing. Use protective coverings like plastic sheets to shield the paper from dust and contaminants. If stacking, do not overload as it may cause the bottom layers to compress and damage. Label the storage area clearly to indicate the contents and check regularly for any signs of deterioration.</p>

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Insulation Green Energy

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords