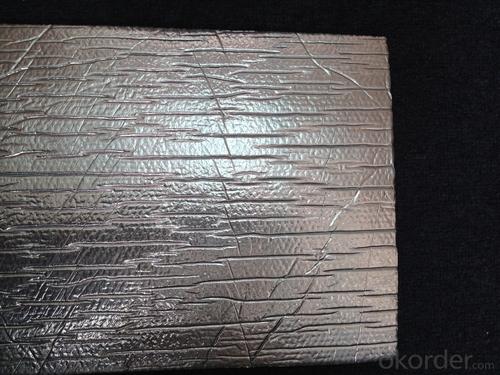

Fiberglass Facing Flexible Ducts Bubble Foil Green

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: What are the potential health hazards linked to the use of synthetic materials such as black fiberglass tissues?

- <p>While synthetic materials like black fiberglass tissues have various applications due to their durability and strength, there are health risks associated with their use. Inhalation of fiberglass dust or fibers can cause respiratory issues, including irritation and, in severe cases, respiratory diseases. Prolonged exposure may lead to conditions like fiberglass lung, a form of pneumoconiosis. It's crucial to use proper protective equipment and ventilation when handling these materials to minimize health risks.</p>

- Q: This question asks about the methods used by manufacturers to maintain the quality of black fiberglass tissue during the manufacturing process.

- <p>Manufacturers ensure the quality of black fiberglass tissue during production through several key steps. They start with high-quality raw materials, such as virgin glass fibers and resins, to ensure strength and durability. They also implement strict quality control measures, including regular testing of the tensile strength, flexibility, and uniformity of the fibers. Advanced manufacturing techniques, such as precision weaving and controlled resin application, are used to maintain consistency in the product. Additionally, environmental controls like temperature and humidity regulation are maintained to prevent variations in the material properties. Finally, post-production inspections and testing are conducted to verify that the final product meets all quality standards before it is released to the market.</p>

- Q: What are the environmental advantages of using black fiberglass tissues compared to paper tissues?

- <p>Black fiberglass tissues, also known as black cellulose tissues, offer several environmental benefits over paper tissues. They are made from a blend of cellulose fibers and are designed to be more durable and reusable, reducing the need for disposable paper products. This can lead to less deforestation and waste in landfills. Additionally, black fiberglass tissues are often more resistant to tearing and can hold up better in wet conditions, reducing the need for multiple tissues. This durability can decrease the overall consumption of tissues, which in turn can lessen the environmental impact associated with the production and disposal of paper products.</p>

- Q: Is it possible to use black fiberglass paper for the interior of a car?

- <p>Yes, black fiberglass paper can be used for car interiors. It is a durable and heat-resistant material that can be used for various interior applications such as lining the trunk, under the hood, or as a protective layer on the floor. However, it's important to ensure that the fiberglass paper is of high quality and properly installed to avoid any potential issues with durability or safety. Always follow the manufacturer's guidelines and consider professional installation for best results.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other sound insulation materials, focusing on their properties and effectiveness.

- <p>Black fiberglass tissue is a type of sound insulation material known for its lightweight, flexibility, and high sound absorption capabilities. Compared to other materials, it offers excellent thermal insulation and resistance to moisture and fire. However, it may not be as dense or heavy-duty as some alternatives like mass-loaded vinyl or certain types of acoustic foam, which can provide better soundproofing in high-noise environments. Black fiberglass tissue is also sensitive to physical damage, which can reduce its effectiveness over time. It's important to consider the specific application and environmental factors when choosing the right sound insulation material.</p>

- Q: The user is asking for the cost of a specific material, black fiberglass tissue.

- <p>The price of black fiberglass tissue can vary significantly based on factors such as quality, thickness, and the quantity being purchased. It's also subject to market fluctuations and regional differences. As of my last update, prices could range from a few dollars per square meter for lower grades to over a hundred dollars for high-quality, specialized grades. For the most accurate and current pricing, it's best to contact suppliers directly or check online marketplaces that sell such materials.</p>

- Q: This question asks for methods to properly store and transport black fiberglass tissue, a material that requires careful handling to maintain its integrity.

- <p>To effectively store and transport black fiberglass tissue, ensure the following: Store the tissue in a cool, dry place away from direct sunlight to prevent degradation. Use airtight containers or wrappings to protect it from moisture and dust. When transporting, use a clean, dry vehicle and avoid stacking heavy items on top to prevent compression damage. Secure the material to prevent shifting during transit. Handle the tissue with clean, dry hands or gloves to avoid contamination. Always follow the manufacturer's guidelines for specific storage and transport recommendations.</p>

- Q: This question asks for guidance on selecting a dependable supplier for black fiberglass tissues, a material used in various industries.

- <p>To choose a reliable supplier of black fiberglass tissues, consider the following: Check their industry reputation and customer reviews. Ensure they have the necessary certifications and quality control measures in place. Evaluate their product quality by requesting samples. Assess their delivery times and reliability. Consider the supplier's financial stability and history. Look for a supplier that offers good customer service and after-sales support. It's also important to compare prices and negotiate terms that fit your budget and requirements.</p>

- Q: Can old black fiberglass tissues be repurposed for uses like insulation or craft projects?

- <p>Yes, old black fiberglass tissues can be repurposed for various uses. They are often used for insulation due to their insulating properties, which help retain heat and reduce energy loss. For craft projects, they can be used for creating textured surfaces or as a base for other materials. However, it's important to handle them with care as they can be harmful if inhaled or if the fibers come into contact with the skin. Always wear protective gear like gloves and masks when handling fiberglass materials.</p>

- Q: What distinguishes black fiberglass from other types of glass fiber in terms of properties and applications?

- <p>Black fiberglass is a type of glass fiber that has been treated with a black pigment or dye, which gives it a distinct appearance and specific properties. Unlike other types of glass fibers which can be clear or have other colors, black fiberglass is primarily used for aesthetic purposes or to absorb light, reducing glare and reflections. It is often used in applications where a dark, non-reflective surface is desired, such as in some types of automotive components, exterior building materials, or in certain industrial settings. Other types of glass fibers may be used for their strength, insulation properties, or electrical non-conductivity, and are not necessarily colored. The choice between black fiberglass and other types of glass fibers depends on the specific requirements of the application in terms of appearance, performance, and functionality.</p>

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Foil Green

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords