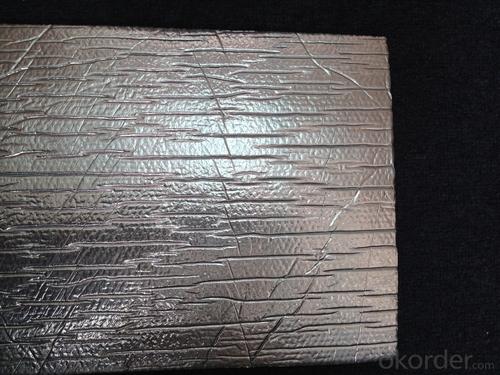

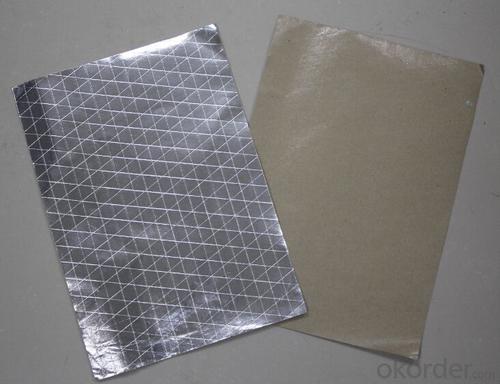

Fiberglass Facing Flexible Ducts Bubble Foil Glasswool

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: Is it possible to use black fiberglass tissue as an insulating material within walls?

- <p>Yes, black fiberglass tissue can be used for insulation in walls. It is a type of fiberglass insulation that is often used in residential and commercial buildings due to its effectiveness in reducing heat transfer and providing thermal insulation. Black fiberglass tissue is made from glass fibers and has a high resistance to heat flow, which helps to maintain a comfortable temperature inside the building. It is also known for its durability and resistance to moisture, making it a popular choice for wall insulation. However, it's important to follow proper installation procedures and safety precautions to ensure the insulation's effectiveness and to protect against potential health risks associated with fiberglass.</p>

- Q: Is it possible to utilize black fiberglass tissue as a flooring material in high-rise constructions?

- <p>Yes, black fiberglass tissue can be used for flooring in high-rise buildings. It is known for its high strength, durability, and resistance to various environmental factors. Fiberglass tissue is often used in composite materials and can be combined with other materials to create a strong and stable flooring solution. However, it's crucial to ensure that the specific type of fiberglass tissue meets the necessary safety standards and building codes for high-rise construction, as well as to consider its fire resistance and load-bearing capabilities.</p>

- Q: What are the ecological effects associated with the utilization of black fiberglass tissue?

- <p>The environmental impact of using black fiberglass tissue is primarily associated with its production and disposal. During production, it can release harmful chemicals and particulates into the air, contributing to air pollution. Additionally, fiberglass is not biodegradable, which means it persists in landfills and can leach chemicals into the soil and groundwater, potentially harming ecosystems. The dark color of black fiberglass may also absorb more heat, which could contribute to the urban heat island effect. However, it's important to note that the environmental impact can be mitigated through proper waste management and recycling programs, which are becoming more prevalent as awareness of environmental issues grows.</p>

- Q: What is the standard thickness measurement for black fiberglass paper towels?

- <p>The thickness of black fiberglass paper towels can vary depending on the manufacturer and the specific product. Generally, these towels are known for their durability and thickness compared to standard paper towels. However, without a specific product reference, it's challenging to provide an exact measurement. Typically, they might range from 0.1 to 0.5 millimeters in thickness, but for precise information, one should refer to the product specifications or contact the manufacturer directly.</p>

- Q: This question asks about the impact of black fiberglass tissue on the quality of air inside residential homes.

- <p>The use of black fiberglass tissue in residential homes can affect indoor air quality in various ways. Black fiberglass is a type of insulation material that can help retain heat and reduce energy costs. However, if it contains certain chemicals or if it's improperly installed, it may release fibers or particles into the air, potentially causing respiratory issues or allergies. Additionally, if the fiberglass is not treated to resist moisture, it could lead to mold growth, further impacting air quality. It's important to ensure that any fiberglass insulation used in homes is of high quality, properly installed, and treated to prevent such issues. Regular maintenance and air quality checks can also help maintain a healthy indoor environment.</p>

- Q: Is it possible to utilize black fiberglass tissue as an insulating material within the structure of greenhouses?

- <p>Yes, black fiberglass tissue can be used for insulation in greenhouses. It is known for its thermal insulation properties, which can help retain heat inside the greenhouse, reducing the need for additional heating and maintaining a stable temperature. Additionally, black fiberglass is resistant to moisture and pests, making it a durable choice for greenhouse insulation. However, it's important to ensure proper installation and ventilation to prevent any potential issues related to condensation or air quality.</p>

- Q: Can I repurpose old black fiberglass tissues for cleaning purposes?

- <p>Yes, you can use your old black fiberglass tissues to make cleaning cloths or wipes. Fiberglass tissues are durable and can effectively pick up dirt and grime. However, it's important to ensure that the tissues are clean and free from any contaminants before repurposing. Cut them into desired sizes and use them for general cleaning tasks. Be cautious with the edges as fiberglass can be sharp. Always handle with care and consider wearing gloves to avoid irritation or injury.</p>

- Q: Is it possible to utilize black fiberglass tissues for domestic cleaning purposes?

- <p>Black fiberglass tissues are not typically recommended for household cleaning tasks. Fiberglass, especially when in a loose or frayed state, can be abrasive and may scratch surfaces. It can also leave behind fibers that are difficult to remove. For cleaning, it's better to use materials specifically designed for the purpose, such as microfiber cloths, which are gentle on surfaces and effective at picking up dirt and dust without scratching.</p>

- Q: This question asks about the proper storage methods for black fiberglass paper.

- <p>To store black fiberglass paper, follow these guidelines: Keep it in a cool, dry place away from direct sunlight and moisture. Ensure the storage area is well-ventilated to prevent the buildup of humidity. Store the paper on flat surfaces to avoid bending or creasing. Use protective coverings like plastic sheets to shield the paper from dust and contaminants. If stacking, do not overload as it may cause the bottom layers to compress and damage. Label the storage area clearly to indicate the contents and check regularly for any signs of deterioration.</p>

- Q: Is it possible to utilize black fiberglass tissue as a material for facial tissues?

- <p>No, black fiberglass tissue is not suitable for use as facial tissues. Fiberglass is a type of fiber made from glass, which is rough and can be abrasive on the skin. It is commonly used for insulation and reinforcement in construction and automotive industries. Facial tissues, on the other hand, are made from soft materials like cellulose pulp from wood, which is gentle on the skin. Using fiberglass for facial tissues could cause skin irritation and is not hygienic or safe.</p>

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Foil Glasswool

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords