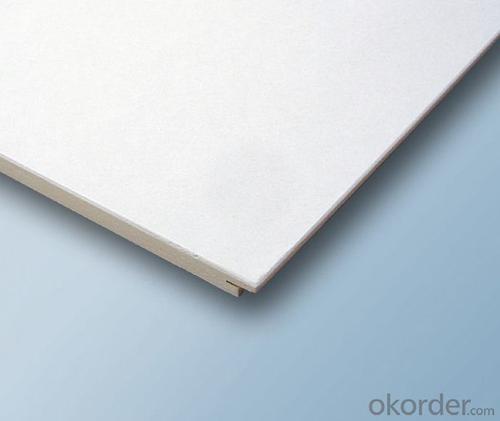

Fiberglass Acoustic Ceiling Tiles - Density 100k Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The tiles are manufactured from high density fiberglass wool.The visible face has a decorative fiberglass tissue and the back of the tile is covered with normal tissue.The four edges of the tile are sealed and have grooves. It can be jointed together without suspended system. The tiles will cover the suspension system after installation. They are are suitable for loe flap ceiling space and concrete-made, wooded-made or gymsum ceiling.

Installation method:

Use screw to fix the smooth roof. The tiles can be connected after making grooves on each two jointed edges.

Tiles are easy to trim and install

Both inches and metric grids are available

Main Characteristic:

Non-combustible

No sagging,wrapping or delaminating

Green building material

Excellent sound absorption

Application:

Halls,classrooms,offices,shopping centers.etc.

Acoustic fiberglass ceiling contains a better perfomance in tension strong, light weight, so it is easy to trim and install for interior decoration, with T-grids for suspension system or glue, nail or good material could come with fiberglass ceiling baord. Thus an excellent artical work need a high quality acoustic ceiling board, also high quality.

Energysaving is a trend for our 21' era, new product like fiberglass ceiling tile could in place of traditional products one day. Which depends on functional characters: little deflection of geometry dimention, no radiocative property, specific activity of 226Ra: Ira ≤1.0 and specific activity of 226 Ra 232 Th, 40 K: Ir ≤ 1.3. Both products and packages can be recycled.

- Q: Glue production in the "volt plastic" What does it mean

- 1. The surface of the object first with sandpaper steel brush clean, dust and oil can be cleaned before the smooth surface should be rough. 2. Extrude the same amount of glue and curing agent mixed evenly, and please at room temperature 18 ~ 25. C under about 2 minutes to complete Bi 3. The two joints must be coated with adhesive, and immediately confinement, and then use the clip tape or weight will be part of the joint pressure, and fixed for 10 minutes, after 30 minutes after the joint can be used.

- Q: Properties of thermoplastic composites

- Talc-filled PP has high rigidity, high strength, excellent heat aging resistance and cold resistance. Talc powder reinforced PP has important applications in interior decoration, such as for ventilation system parts, dashboards and automatic brake control bars, such as the United States HPM company with 20% talc filled PP made of honeycomb structure sound Ceilings and cars of the rocker lifter Coil shell. ? Mica composite material with high rigidity, high heat distortion temperature, low shrinkage, low flexibility, dimensional stability and low density, low price and other characteristics, the use of mica / polypropylene composite materials can be made car dashboard, headlamp protection ring Plate cover, door rails, motor fans, shutters and other components, the use of the damping of the material can be made audio parts, the use of its shielding can be made battery box.

- Q: We recently purchased a condo with an unfinished walkout basement. Two walls above grade have fiberglass batts with a plastic vapor barrier. The ceiling has exposed fiberglass batts. We have no immediate plans to finish the basement, but I will have a washer and dryer down there. There is an electric blower to keep the pipes from freezing, but no other source of heat. I am concerned about exposure to the fiber from the ceiling batts and am wondering if there is any covering I can use to encapsulate the fiberglass, or would removal be the best option? I heard that to cover in plastic would not be a good idea because of condensation. We live in a cold winter climate. Thank you.

- Short of a dropped ceiling, you might try stapling kraft paper or the such over the fiberglass. Lets the insulation breathe, but covers it up.

- Q: Do the glass fiber composite material be bad for the human body?

- Glass wool is a category in glass fiber, is a kind of artificial inorganic fiber. Using quartz sand, limestone, dolomite and other natural ore as the main raw material, with some soda ash, borax and other chemical raw materials into glass. Glass wool can be regarded as porous material, with good insulation, sound absorption performance.

- Q: Waterproof acceptance how to accept kitchen and toilet waterproof is done?

- 1. Waterproof material performance should be consistent with the provisions of the relevant national standards, and product certification should be a certificate. 2. Base surface should be flat, no hollowing, from the sand, cracking and other defects. Base water content should meet the construction requirements of waterproof materials. The waterproof layer should extend from the ground to the wall, 250mm above the ground. Bathroom wall waterproof layer height of not less than 1800mm. 3. Waterproof cement mortar leveling layer and foundation with dense, no hollowing, smooth and smooth surface, no cracks, from the sand, yin and yang angle made of circular arc. 4. Coating waterproof layer brushing uniform, the thickness of the product to meet the technical requirements, the general thickness of not less than 1.5mm do not reveal the end. 5. The use of construction stubs should be along the direction of the flow of water, lap width of not less than 100mm, the use of two or more fiberglass cloth up and down when the overlap should be staggered width of one-half. 6. The surface of the coating is not blistering, does not flow, smooth without bumps, and pipe fittings, sanitary ware to the ground, floor drain, drain seams tightly rounded and tight. The above is the content of the waterproof acceptance criteria, we hope to help. This knowledge will be used in the decoration, as long as more knowledge of these knowledge will be useful for your decoration.

- Q: We had our carpets removed a while ago and installed laminate flooring instead.As a result, the house is not as warm as it used to be.Will it help if I add R13 insulation in the basement ceiling ? Will it keep the living room floor (which is just above the basement) warmer ?On the same manner, will adding another layer of insulation to the attic help in the winter and summer as well ?As for the mositure barrier paper, if I understand correctly, it should be facing up both cases, right ?

- Every home and layout is different so it's difficult to give the right answer. Adding insulation to the basement ceiling would help out and would not hurt anything but why is it so much colder in the basement? Yes basements always appear to be cooler but you might want to look into that. Typically in basements very cheap single pane windows are installed, box sills around the primeter should also have insulation in them. For your attic; at a quick glance if you can see the ceiling joists on the floor of the attic you need more insulation. Common fiberglass batts you would find are R-9 up to possibly R-19 for a single layer, you should have at least and R-28, if not add additional. In northern regions new construction they are putting in R-42. If you have a loose fill insulation the rule of the thumb is R-3 per inch of product, just a guideline if manufacture spec's are not available. Vapor barrier always goes towards the warm side; in the attic the barrier would go down or closest to the drywall on the ceiling below. Basement probably isn't has picky but technically would go up against the underside of the floor.

- Q: When I moved into my house the ceiling was cracked from the ceiling fan out to the walls in two directions. I don't want to put new wall board up and repairing the crack is not possible according to my Husband. What are some ways to cover the ceiling up?

- If the ceiling is still shifting, it will crack again, no matter what you do. If not, then you might be able to fix it with joint compound and drywall tape. I don't know if it's the same, but we recently had a crack going from ceiling to floor. We had a drywall guy come out, who made the crack a little bigger, then remudded and retaped and retextured. (Actually, the problem was that it hadn't been taped the first time.)

- Q: What signs on plastic products are non-toxic

- HDPE high density polyethylene Common white vials, cleaning supplies, bath products. Do not use it again Cups, or used to make other containers. Clean is not complete, do not use.

- Q: What is the characteristics of the vitreous sound board?

- Can effectively control and adjust the indoor reverberation time, reduce noise and improve sound quality. Fiberglass sound absorption ceiling has a good thermal insulation properties for air-conditioned places, can reduce the impact of the outside world on the indoor temperature, thus effectively saving energy Fiberglass sound - absorbing cements hardly absorb moisture from the air, have excellent moisture resistance, and maintain stability from size to flatness in any humid environment.

- Q: Home improvement waterproofing process and what is the standard

- Waterproof Acceptance Tips: 1, closed water test: refers to do the retaining wall, the water to be tested in the test space to test whether there is leakage phenomenon. Waterproof layer construction more common in the cabinet, bathroom. Acceptance, we must do a closed-water test, and both sides identified by the test results can be done after the surface layer. If not done closed water test or test failed to do the surface layer, the future leakage, only the surface layer all removed, to start again. The waterproof floor of the room with yellow clay, low-grade cement mortar and other materials to be a 30 to 50 high-mm block (Kan), the leak and other tightly closed. Ground water to form a depth of 20 to 30 mm deep pool. 2 water savings 24 hours later, together with the property sector, the corresponding bathroom downstairs neighbors, to test whether the lower floor floor leakage. Common signature acceptance. If there is leakage to do or repair the waterproof layer, after the order in accordance with the above closed water test. Until no leakage is acceptable. 2, the water test: for the construction of light wall waterproofing acceptance, should take the water test, that is, the use of water pipes in the waterproof paint on the wall from top to bottom non-stop spray 3 seconds, 4 hours after the observation wall The other side of the body will appear whether the phenomenon of penetration, if there is no penetration phenomenon can be considered waterproof wall construction acceptance.

Send your message to us

Fiberglass Acoustic Ceiling Tiles - Density 100k Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords