Usg Fiberglass Ceiling Tiles - Acoustic Tegular Edge Ceiling Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

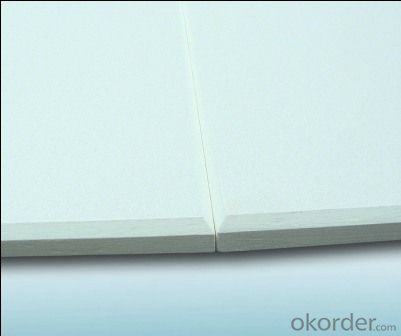

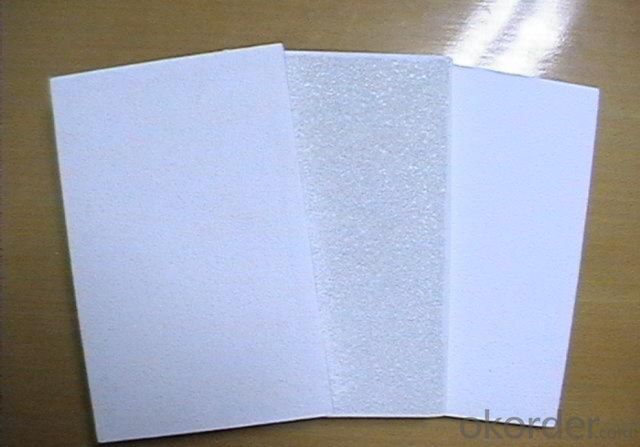

The tile is made by high-density fiberglass with compound decoration wool on the surface and fiberglass wool on the back .The edges are painted. With the characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The panels are udes widely in schools, offices, music studios, lecture theatres,

multi purpose halls, interview rooms, training areas and cinemas. They meet the

requirements of BB93 of Building Regulations for acoustics in school buildings and

are Class O fire rated hence meeting the Fire Regulations as well.

Product Advantages:

Saves headroom space because exceptional noise absorption effectiveness is achieved by low (30mm) material thickness.

Surfaces can be emulsion painted to any colour without significant loss in noise

absorption. Increase savings due to fast and easy installation.Lightweight and therefore are ideal for adhering to ceilings, which do not have a very high load bearing capabilities.

Meets BB93 standards for school acoustics as well as common areas in flats for Building

Regulations.

Reinforced edges for increased durability.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

Question 1: Where is your factories?

Our factories in different areas of China, such as Shandong Province, Hebei Province, etc.

Question 2: May I get some samples of the product?

Yes, of course. If you need, we could sent you the small samples by the reliable delivery company such as DHL etc.

Images:

- Q: My bathroom because of a variety of pipelines have been well, if the installation of tiles, then all the re-waste and then get, very troublesome! I would like to ask you there is no one can brush directly on the bathroom wall paint, asked to take a shower when the cold water will not fall in the above, hot water rushed in the above will not have any reaction. Have a friend please know please! Thank you!

- Bathroom waterproof two kinds of paint (1) synthetic polymer polyurethane waterproof coating (corner, etc. need to add polyester cloth, glass cloth, etc.) (2) polymer modified asphalt SBS waterproof coating (need to add carcass reinforcement polyester cloth, glass cloth, etc.).

- Q: Specification for acceptance of glass cord sound - absorbing cotton

- "The latest switchgear testing test new technology, new equipment, new standards and product quality acceptance of the book"

- Q: what is ceiling soundproofing?

- A soundproofing ceiling is a ceiling that has been designed to cut down on the noise that is transferred from overhead to the area below a soundproof ceiling is a nose addition for people who live in apartment , but surprisingly many people who live in private home are also interesting in soundproof their ceiling

- Q: I would like to open the interior decoration materials shop need to enter what goods? How much cost? Where is the supply?

- Building materials and more to see your local situation to set a!

- Q: How to enhance the sound insulation of the room?

- The room is to take a strict sound insulation measures on the walls, floors and ceilings. The final result is the construction of a room inside the room. All the studios use this structure. Of the sound insulation characteristics of more than -50dB. Even with the ideal sound insulation features up to -60dB ~ 65dB recording studio comparable to the inside and outside the wall completely isolated, do not send any sound vibration, "room" structure is necessary The use of isolation devices, the construction of more complex. This level of noise walls, do not allow such as power supply, audio equipment, telephone, air conditioning and other sockets have installation gap.Therefore, the actual plan, should consult the corresponding qualification of large decoration company. "Room room" manufacturing costs will be much higher than any of the previous transformation method, up to more than 10,000 yuan per square meter.Obviously this is not the general working class can expect the sound insulation to pay attention to the level of their own home theater To achieve what kind of standards, the mind to have a number, so the system should take appropriate measures to spend the least money with their own economic capacity, appreciation of the level of sound insulation is the most important.

- Q: What is the role of chemically tinned magnesium chloride?

- Enhance the conductivity of the solution

- Q: Hello, our house has a big crack in the ceiling running from on wall to the other ( only about 3 feet cause its a entrance way) and I was wondering if there is anyway to fix it properly? We will be selling the home in a year and don't want it to scare anyone off BUT also don't want to just paint over it ( may get sued for concealing a problem). Any ideas or thoughts? Are we screwed and may have to leave it and the house won't sell as fast?:(

- First clean the crack out as deep as you can ,and about one half inch or more if needed deep. Then fill with dry wall compound level with old plaster. Let this dry a day.

- Q: I was replacing a bathroom fan and the new bathroom fan is bigger than the old one. I took out the old one. Then I used a pencil and traced around the new fan. Then I used a reciprocating saw for the first time and got a little crazy with it. Now the hole is slightly too big and when I put the grill cover on the fan, I can see the hole. I'm not sure what to do now. I still got old pieces of the ceiling. Maybe I can do something with it?

- Cut out enough of the ceiling to put small pieces of plywood behind the old drywall. Put the plywood behind it and screw a few screws through the old drywall and plywood so you can screw a new piece of drywall to it. Basically just using it as a backer-board. Then you have to put fiber tape or mesh tape over the seam and spackle it and feather it out so it isn't noticeable. Then sand it down and re-paint. It sounds like alot of work, but its 3 work hours at the most if you have quick drying spackle.

- Q: Home improvement, tooling need to use what decorative materials, all have their own purposes, ask you prawn

- Putty powder, used to brush the wall. The The Gypsum board, ceiling. The The Flooring, lighting, etc etc. The The

- Q: What is the characteristics of the vitreous sound board?

- Has a good shape, small density, thermal conductivity 彽, insulation adiabatic, sound-absorbing performance, corrosion resistance, chemical stability. Glass fiber sound-absorbing panels referred to as glass wool or sound insulation cotton glass wool is a category of glass fiber, is a kind of artificial inorganic fiber. Glass wool is the melting glass fiber, the formation of cotton-like material, chemical composition of glass, is an inorganic fiber.

Send your message to us

Usg Fiberglass Ceiling Tiles - Acoustic Tegular Edge Ceiling Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords