Extrusion Profiles Aluminum Coil in Accordion to European Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coil in Acoording to Europ Standard Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Coil in Acoording to Europ Standard Applications:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

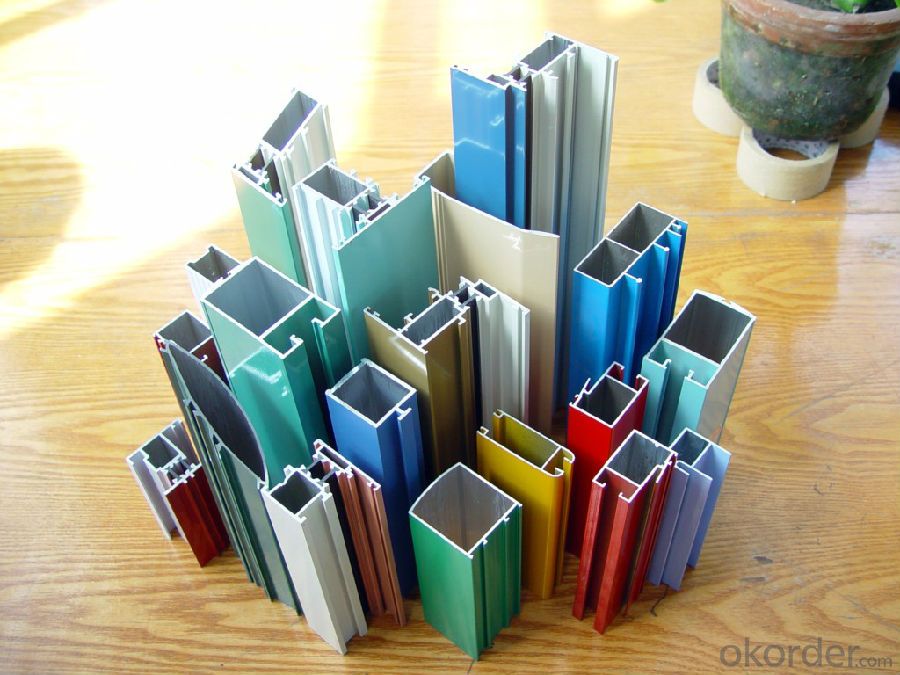

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

Images of the AAluminium Coil in Acoording to Europ Standard:

AAluminium Coil in Acoording to Europ Standard Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: Can aluminum profiles be an alternative to steel or other materials?

- Many applications can consider aluminum profiles as a viable alternative to steel or other materials. Aluminum profiles possess several advantages over steel, including their lightweight nature, corrosion resistance, and durability. The low weight of aluminum profiles is a key benefit. Aluminum is approximately one-third the weight of steel, making it ideal for weight reduction purposes. Its lightweight property also makes it easier to handle, transport, and install, which ultimately reduces costs and labor requirements. Furthermore, aluminum profiles exhibit excellent corrosion resistance, especially when compared to steel. When exposed to air, aluminum naturally forms a protective oxide layer that prevents further oxidation and corrosion. This makes aluminum profiles suitable for industries such as construction, automotive, aerospace, and marine, where exposure to moisture, saltwater, or harsh weather conditions is common. Another advantage of aluminum profiles is their high strength-to-weight ratio. Aluminum alloys can be engineered to provide exceptional strength while still being lightweight. This makes them an excellent choice for structural applications that require both strength and weight reduction. In addition, aluminum profiles are highly durable and can withstand extreme temperatures. Aluminum has a melting point of 660 degrees Celsius, which is significantly higher than most other non-ferrous metals. This makes it suitable for applications where exposure to high temperatures or thermal stress is expected. Aluminum profiles are also easily fabricated, allowing for complex shapes and designs. They can be extruded, machined, welded, or formed into various configurations to meet specific requirements. This flexibility in manufacturing processes makes aluminum profiles a versatile material choice. However, it is important to note that aluminum profiles may not be suitable for all applications. Steel still offers superior strength and rigidity, making it more appropriate for heavy-duty applications or areas requiring high impact resistance. Additionally, the cost of aluminum profiles can be higher compared to steel, depending on the specific alloy and manufacturing processes involved. In conclusion, aluminum profiles can be considered as a viable alternative to steel or other materials in many applications. Their lightweight nature, corrosion resistance, high strength-to-weight ratio, durability, and ease of fabrication make them an attractive choice for various industries. However, it is crucial to carefully consider the specific requirements of each application before deciding on the most suitable material.

- Q: The original aluminum is silver, but now the market has black, yellow and green, aluminum radiator, radiator is the color what are formed by oxidation of different colors, what are the benefits of it, are used in the above types of products?

- In this process, there is no difference for several different color film properties, the only difference is that the surface of different colors can increase the appearance of the product, can choose different colors according to the requirements of different products.

- Q: How do you prevent discoloration or fading of aluminum profiles?

- To prevent discoloration or fading of aluminum profiles, it is important to apply a protective coating or finish on the surface of the profiles. This can be done using methods such as anodizing, powder coating, or painting. These coatings act as a barrier, shielding the aluminum from exposure to UV rays, moisture, and other environmental factors that can cause discoloration and fading. Regular cleaning and maintenance also play a crucial role in preventing discoloration, as removing dirt, grime, and pollutants promptly can help preserve the appearance and integrity of the aluminum profiles.

- Q: This question asks for an explanation of the manufacturing process of aluminum profiles.

- <p>Aluminum profiles are made through a series of processes starting with the selection of high-quality aluminum ingots. These ingots are melted in a furnace and then extruded through a die to create the desired profile shape. The extrusion process involves forcing the molten aluminum through a shaped opening in the die, which gives the aluminum its final form. After extrusion, the profiles are cooled, straightened, and cut to length. They may then undergo secondary processes such as anodizing, powder coating, or painting for enhanced durability and appearance. Finally, the profiles are inspected for quality and packed for distribution.</p>

- Q: What are the bending radii for different aluminum profiles?

- The bending radii of various aluminum profiles can differ based on the profile's specific shape and thickness. Generally, aluminum profiles can be bent to a minimum radius, usually around 1.5 to 2 times the material's thickness. For instance, if you possess an aluminum profile with a thickness of 1mm, the minimum bending radius would be approximately 1.5 to 2mm. Similarly, if the profile's thickness is 3mm, the minimum bending radius would be about 4.5 to 6mm. It's important to note that these values are approximate and can vary depending on the particular alloy and temper of the aluminum. Moreover, the bending process itself, including the equipment and method employed, can also impact the achievable bending radii. To ensure precise bending, it is advisable to seek guidance from the manufacturer or a professional fabricator who can provide specific instructions and recommendations for bending radii based on the specific aluminum profile you are working with.

- Q: How do aluminum profiles contribute to daylighting strategies?

- Aluminum profiles contribute to daylighting strategies by being used in the construction of windows, doors, and skylights. These profiles are designed to be lightweight, durable, and have excellent thermal properties. They allow for larger glass panels, maximizing the amount of natural light that enters a space. Additionally, the profiles can be customized to accommodate different glazing options, such as low-emissivity coatings or solar control films, which help regulate heat gain and loss. Overall, aluminum profiles enhance daylighting strategies by promoting the use of natural light, reducing reliance on artificial lighting, and improving energy efficiency in buildings.

- Q: Are aluminum profiles suitable for high-temperature environments?

- No, aluminum profiles are not generally suitable for high-temperature environments as they have a low melting point and can deform or lose their structural integrity at high temperatures.

- Q: This question asks for the method to determine the quantity of aluminum profiles required for a construction project.

- <p>To calculate the amount of aluminum profiles needed for a building project, follow these steps: 1. Determine the architectural design and specifications of the project to understand where aluminum profiles will be used. 2. Measure the dimensions of the areas requiring aluminum profiles, such as window frames, door frames, or structural supports. 3. Calculate the total linear footage of aluminum needed by multiplying the length of each profile by the number of profiles required. 4. Factor in additional materials for joints, connections, and potential waste. 5. Consult with suppliers or use industry-standard conversion factors to determine the weight or volume of aluminum profiles based on the linear footage. 6. Review the calculations and adjust for any changes in the project design. This process ensures you have the correct amount of aluminum profiles for your construction needs.</p>

- Q: Are aluminum profiles suitable for signage and advertising displays?

- Yes, aluminum profiles are highly suitable for signage and advertising displays. Aluminum is a lightweight and durable material that is resistant to corrosion, making it ideal for outdoor applications. It can withstand various weather conditions without losing its structural integrity, ensuring longevity and reliability for signage and advertising displays. Additionally, aluminum profiles offer versatility in design and customization. They can be easily shaped and molded into different forms and sizes, allowing for the creation of eye-catching and unique displays. Aluminum profiles also provide a sleek and modern appearance, adding a professional touch to any signage or advertising display. Furthermore, aluminum profiles are highly compatible with other materials commonly used in signage and advertising, such as acrylic, PVC, and LED lighting. This compatibility allows for the integration of different elements, such as illumination, to enhance the visibility and impact of the displays. Moreover, aluminum profiles offer easy installation and maintenance. They can be easily assembled, disassembled, and reconfigured as needed. Their lightweight nature makes them easy to handle, reducing installation time and costs. Additionally, aluminum profiles require minimal maintenance, as they do not rust or deteriorate easily. In conclusion, aluminum profiles are an excellent choice for signage and advertising displays. They offer durability, versatility, compatibility, and ease of installation and maintenance. Whether for outdoor or indoor applications, aluminum profiles can provide a visually appealing and long-lasting solution for effective signage and advertising.

- Q: Are aluminum profiles suitable for automotive racks and carriers?

- Aluminum profiles, indeed, possess the appropriateness for automotive racks and carriers. Being both lightweight and robust, aluminum emerges as an optimal material for instances that prioritize weight reduction, such as automotive racks and carriers. The adaptability and flexibility of aluminum profiles enable their design and engineering to cater to specific requirements, facilitating customization. Besides, aluminum's resistance to corrosion guarantees the endurance and long-lasting nature of automotive racks and carriers, even in unfavorable weather conditions. Moreover, the notable strength-to-weight ratio of this material contributes to an enhanced fuel efficiency and reduced emissions. In summary, aluminum profiles furnish a dependable and efficient resolution for automotive racks and carriers.

Send your message to us

Extrusion Profiles Aluminum Coil in Accordion to European Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords