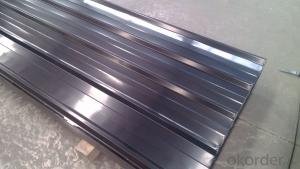

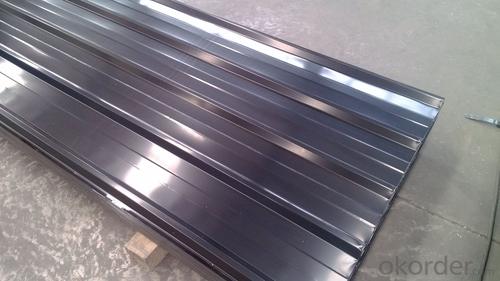

Aluminum Sheets in Pennsylvania - Extruded Aluminum Plate for Roofing Building Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

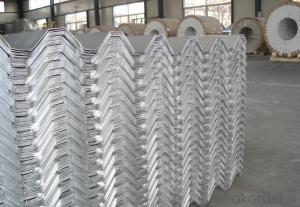

Extruded Aluminum Plate For Roofing Building Application

Specifications

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

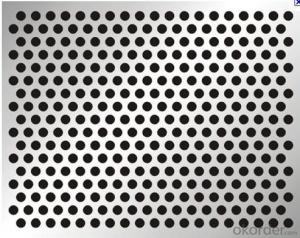

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

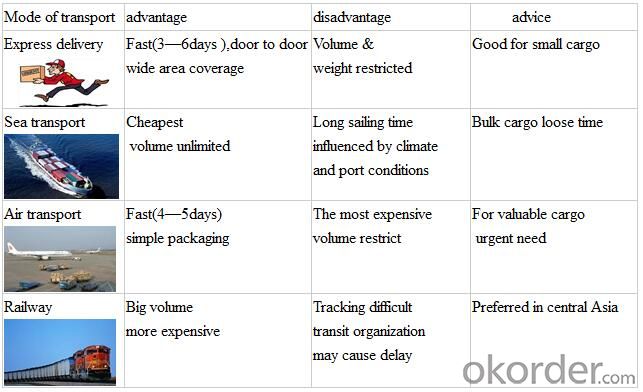

Shipment

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q: Can 101 aluminum sheets be bent or formed into different shapes?

- Certainly! It is indeed possible to bend or shape 101 aluminum sheets into various forms. Aluminum possesses high malleability, meaning it can be shaped effortlessly without any risk of breaking or cracking. The specific grade of aluminum, such as 101, signifies the alloy composition and might possess specific properties that make it more suitable for bending and shaping. Nevertheless, the capacity to bend or shape aluminum sheets also relies on their thickness; thicker sheets may necessitate greater force and specialized equipment. In conclusion, with the correct tools and techniques, it is feasible to bend or shape 101 aluminum sheets into diverse shapes to fulfill specific requirements.

- Q: Are aluminum sheets suitable for signage?

- Yes, aluminum sheets are highly suitable for signage. Aluminum is a versatile material that offers a range of benefits for signage applications. It is lightweight, durable, and resistant to corrosion, making it ideal for both indoor and outdoor signage. Aluminum sheets can withstand harsh weather conditions, including rain, snow, and UV exposure, without deteriorating or fading. They are also easy to work with, allowing for a variety of customization options such as embossing, engraving, and digital printing. Moreover, aluminum sheets are cost-effective and have a long lifespan, ensuring that signage remains in excellent condition for extended periods. Overall, aluminum sheets are a popular choice for signage due to their durability, versatility, and aesthetic appeal.

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: How is aluminum obtained from its ore?

- Aluminum is obtained from its ore through a process called Bayer's process. The ore, known as bauxite, is first crushed and then mixed with a hot solution of sodium hydroxide. This reaction causes the aluminum oxide in the ore to dissolve, forming sodium aluminate. The impurities in the ore, such as iron oxide and silica, remain insoluble. Next, the solution is filtered to remove the insoluble impurities, leaving behind a clear liquid containing sodium aluminate. This liquid is then cooled and treated with carbon dioxide gas, which converts the sodium aluminate into aluminum hydroxide. The aluminum hydroxide is then heated to form alumina or aluminum oxide. This process, known as calcination, involves heating the aluminum hydroxide at high temperatures to remove any remaining water and impurities. Finally, the alumina is mixed with a molten cryolite, which acts as a solvent, and then electrolyzed. Electrolysis involves passing an electric current through the molten mixture, causing the aluminum ions to migrate to the cathode, where they are reduced to form molten aluminum metal. The molten aluminum is then collected and cooled to solidify into ingots or other desired shapes. In summary, aluminum is obtained from its ore by first extracting the aluminum oxide using sodium hydroxide, followed by purification and conversion into alumina through calcination. The alumina is then electrolyzed using a molten cryolite, resulting in the production of molten aluminum metal.

- Q: How do aluminum sheets perform in terms of flexural strength?

- Aluminum sheets have good flexural strength, meaning they can withstand bending or flexing without easily breaking or deforming. The specific flexural strength of aluminum sheets can vary depending on factors such as the alloy used and the thickness of the sheet. However, in general, aluminum sheets are known for their ability to maintain their structural integrity under bending forces, making them suitable for various applications that require flexibility and strength.

- Q: What are the standards and certifications available for aluminum sheets?

- Aluminum sheets can be evaluated for quality and compliance with industry requirements through various standards and certifications. Some well-known ones include: 1. ASTM International Standards: Developed by the American Society for Testing and Materials (ASTM), these standards focus on aspects like chemical composition, mechanical properties, and dimensional tolerances. They promote consistent quality across different aluminum sheet products. 2. ISO 9001: This globally recognized certification establishes guidelines for quality management systems. Aluminum sheet manufacturers with ISO 9001 certification demonstrate their commitment to meeting customer requirements, continuous improvement, and strict quality control processes. 3. ASME Standards: The American Society of Mechanical Engineers (ASME) has specific standards for aluminum sheet materials used in pressure vessels, piping, and other applications. These standards ensure the safety and reliability of aluminum sheets in critical applications. 4. MIL-Specifications: The United States Department of Defense (DoD) has developed military specifications (MIL-Specs) for materials, including aluminum sheets. These specifications define the requirements for military-grade aluminum sheets, ensuring their suitability for defense applications. 5. EN Standards: The European Committee for Standardization (CEN) has established a series of European Norm (EN) standards for aluminum and aluminum alloys. These standards cover chemical composition, mechanical properties, and surface finishes, ensuring compatibility and consistency in the European market. 6. RoHS Compliance: Compliance with the Restriction of Hazardous Substances (RoHS) is crucial for aluminum sheets used in electrical and electronic equipment. This certification guarantees that the aluminum sheets are free from hazardous substances, ensuring environmental safety. Manufacturers and suppliers of aluminum sheets must adhere to these standards and certifications to ensure their products are of the highest quality, safety, and suitability for specific applications.

- Q: Can aluminum sheet be used for aircraft skin panels?

- Certainly, aircraft skin panels can indeed be made from aluminum sheet. As a matter of fact, aluminum is extensively employed as the preferred material for constructing such panels owing to its highly advantageous properties. Aluminum possesses the qualities of being lightweight, robust, and resistant to corrosion, rendering it an ideal selection for aircraft production. Moreover, aluminum is effortlessly malleable, facilitating the shaping of the panels into the precise contours and curves necessary for aircraft design. Furthermore, it exhibits commendable heat conductivity, aiding in the dissipation of heat generated during flight. All in all, aluminum sheet is an exceptionally reliable and efficient material for the fabrication of aircraft skin panels.

- Q: Are 101 aluminum sheets suitable for agricultural machinery?

- Indeed, agricultural machinery finds suitability in a total of 101 aluminum sheets. Aluminum, a material that is both versatile and lightweight, brings forth numerous advantages for agricultural machinery. Its outstanding resistance to corrosion becomes particularly vital for equipment that confronts diverse weather conditions and chemicals commonly encountered in the agricultural industry. Furthermore, the strength-to-weight ratio of aluminum proves to be advantageous, permitting an augmented payload capacity and enhanced fuel efficiency. Moreover, the malleability of aluminum allows manufacturers to fashion intricate shapes and designs for machinery components. All in all, the durability, corrosion resistance, and versatility demanded by agricultural machinery are adequately met by 101 aluminum sheets.

- Q: Can 101 aluminum sheets be used in food storage containers?

- Using 101 aluminum sheets in food storage containers is not recommended. These aluminum sheets, often referred to as 101 aluminum, are not suitable for storing food as they are not made from food-grade materials. Typically, they are employed in industrial settings like roofing, construction, and electrical wiring. To guarantee the safety and quality of stored food, it is essential to use containers crafted from food-grade materials such as stainless steel, glass, or food-grade plastic.

- Q: Can aluminum sheets be painted or coated?

- Aluminum sheets have the ability to be painted or coated. Aluminum, being a versatile material, can easily be painted or coated in order to enhance its appearance or improve its performance. The key to successfully painting or coating aluminum lies in adequately preparing the surface and using appropriate primers or coatings specifically designed for aluminum. To achieve this, the aluminum sheet's surface must be thoroughly cleaned, devoid of any oils, dirt, or oxidation, and may require sanding or etching to promote adhesion. Once the surface is prepared, a wide array of paints or coatings can be applied, including liquid paints, powder coatings, and anodizing. These finishes offer various advantages such as heightened corrosion resistance, improved durability, enhanced aesthetics, and even specialized properties like heat resistance or anti-microbial properties. It is crucial to seek professional advice or adhere to the manufacturer's instructions to ensure the correct application and long-lasting effects of the paint or coating on aluminum sheets.

Send your message to us

Aluminum Sheets in Pennsylvania - Extruded Aluminum Plate for Roofing Building Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords