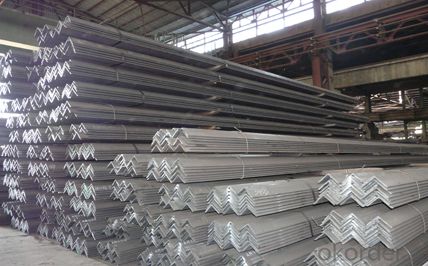

Equal Angle Steel Hot Rolled / Steel Angle Bar /Q235B Angle Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | As standard export package |

| Delivery Detail: | 15days to 20days |

hot rolled equal angle steel/ steel anglesbar /Q235B angle size

Model | Specification | Weight kg/M |

2.5# | 25*3 | 1.124 |

25*4 | 1.459 | |

3# | 30*3 | 1.373 |

30*4 | 1.786 | |

4# | 40*3 | 1.852 |

40*4 | 2.422 | |

40*5 | 2.976 | |

5# | 50*4 | 3.059 |

50*5 | 3.77 | |

50*6 | 4.465 | |

6# | 60*5 | 4.57 |

60*6 | 5.42 | |

6.3# | 63*5 | 4.822 |

63*6 | 5.721 | |

63*8 | 7.469 | |

7# | 70*5 | 5.397 |

70*6 | 6.406 | |

70*7 | 7.398 | |

70*8 | 8.373 | |

7.5# | 75*5 | 5.818 |

75*6 | 6.905 | |

75*7 | 7.976 | |

75*8 | 9.03 | |

75*10 | 11.089 | |

8# | 80*6 | 7.376 |

80*8 | 9.658 | |

80*10 | 11.874 | |

9# | 90*8 | 10.946 |

90*10 | 13.476 | |

90*12 | 15.94 | |

10# | 100*6 | 9.366 |

100*8 | 12.276 | |

100*10 | 15.12 | |

100*12 | 17.898 | |

11# | 110*8 | 13.532 |

110*10 | 16.69 | |

110*12 | 19.782 | |

110*14 | 22.809 | |

12.5# | 125*8 | 15.504 |

125*10 | 19.133 | |

125*12 | 22.696 | |

125*14 | 26.193 | |

14# | 140*10 | 21.488 |

140*12 | 25.522 | |

140*14 | 29.49 |

Equal angle steel Manufacturer from ShangHai China

1.Material: Q235B, SS400, A36, ST37-2, S235JR,Q345,S355JR,SJR275,SM490,ST-52

2.Surface: Oil, Black, Galvanized, Painted

3. Length: 6-12m or according to our clients' requirements

4. Main market: East-south Asia, Mid-east, South America, South Africa

5. Package:load on 20 feet/40 feet container or by bulk according to the quantity and our client's requirement

6. Payment: 100% irrevocable L/C at sight or T/T

7. Delivery time: within 10-15 days after confirming order and deposit received.

8. Applicant: Widely used in all kinds of architecture and engineering structure, such as the beam, Bridges, transmission tower, lifting transportation machinery, the ships, the industrial furnace,container frame and warehouse shelves, etc..

9. Related products available: Steel plates, steel coils, steel angle, H-beam steel, steel channels, I-beams steel , welded pipe, Galvanized pipe, steel rail, steel bar--round , flat ,Checkered and square.

- Q: Can steel angles be used in marine or coastal environments?

- Yes, steel angles can be used in marine or coastal environments. However, it is important to choose the right type of steel that has corrosion resistance properties, such as stainless steel or galvanized steel, to ensure durability and prevent rusting or deterioration caused by the salty ocean air or water exposure. Additionally, proper maintenance and regular inspections are necessary to maintain the integrity of steel angles in these harsh environments.

- Q: Can steel angles be used for electrical conduits or cable trays?

- Depending on project requirements and regulations, steel angles can serve as support structures for electrical conduits or cable trays. These angles are well-known for their strength and durability, making them commonly used as structural supports. However, when considering their use for electrical conduits or cable trays, it is imperative to ensure that they meet the necessary electrical and safety codes. Electrical conduits and cable trays are specifically designed to house and protect electrical wires or cables in a safe manner. These systems must be capable of withstanding the weight of the cables, providing proper grounding, and offering sufficient protection against physical damage, moisture, and other potential hazards. Steel angles can be employed as support structures for electrical conduits or cable trays, providing a robust framework for the installation and securement of the system. However, it is crucial to ensure that the steel angles are effectively grounded, insulated, and guarded against corrosion to meet all electrical safety standards. Furthermore, the selection of the appropriate size and dimensions for the steel angles should be based on the weight and size of the cables or wires being installed. To guarantee compliance with all necessary requirements, it is important to consult with electrical engineers or professionals who are familiar with local electrical codes and standards. In conclusion, while steel angles can be utilized for electrical conduits or cable trays, it is essential to carefully consider the specific requirements and regulations of the project to ensure electrical safety and compliance.

- Q: Can steel angles be used in seismic applications?

- Yes, steel angles can be used in seismic applications. Steel angles are commonly used in seismic applications due to their high strength and ductility properties. They are often used in the construction of steel moment frames and bracing systems, which are designed to resist lateral forces caused by seismic events. Steel angles are particularly effective in providing structural support and stability in areas prone to earthquakes. They can be used as diagonal braces, gusset plates, or stiffeners to enhance the seismic performance of buildings and structures. Additionally, steel angles can be easily fabricated and installed, making them a cost-effective choice for seismic applications.

- Q: Can steel angles be used in transportation or infrastructure projects?

- Yes, steel angles can be used in transportation or infrastructure projects. Steel angles are commonly used in construction due to their strength and durability. They are often used to provide structural support and stability in various applications such as bridges, buildings, highways, and railways. In transportation projects, steel angles can be used for constructing vehicle ramps, guardrails, and support structures for overhead signs. In infrastructure projects, they can be used for constructing retaining walls, foundations, and supporting structures for utility installations. The versatility and reliability of steel angles make them a popular choice in these types of projects.

- Q: What are the different surface treatments available for galvanized steel angles?

- To enhance the appearance, durability, and resistance to corrosion of galvanized steel angles, there are various surface treatments available. Some commonly used treatments include: 1. Powder coating: This method involves applying a dry powder onto the surface of the galvanized steel angle, followed by heating to create a long-lasting and visually appealing finish. Powder coating can be customized to achieve different colors and textures, resulting in a high-quality surface treatment. 2. Painting: Galvanized steel angles can also be painted with different coatings, such as epoxy, polyurethane, or enamel paint. Painting adds an extra layer of protection against corrosion and can be tailored to meet specific aesthetic requirements. 3. Hot-dip galvanizing: This treatment is the initial process for galvanized steel angles. It involves immersing the angles in a bath of molten zinc, which forms a protective layer on the surface. Hot-dip galvanizing offers excellent corrosion resistance and is particularly suitable for outdoor applications. 4. Zinc electroplating: Similar to hot-dip galvanizing, zinc electroplating applies a thin layer of zinc to the steel angle's surface through an electrochemical process. This treatment offers good corrosion protection and can be combined with other surface treatments to enhance durability. 5. Anodizing: Anodizing is commonly used for aluminum surfaces but can also be applied to galvanized steel angles. This process creates a controlled oxide layer on the surface, improving corrosion resistance and providing a decorative finish. 6. Passivation: Passivation is a chemical treatment that eliminates iron and other impurities from the surface of galvanized steel angles. It enhances the steel's corrosion resistance by creating a passive oxide layer. When selecting a surface treatment for galvanized steel angles, it is crucial to consider specific application requirements, budget constraints, and desired aesthetic appearance. Seeking advice from professionals or suppliers can help determine the most suitable treatment for your needs.

- Q: Are steel angles suitable for manufacturing shelving units?

- Absolutely, steel angles are absolutely fitting for the production of shelving units. Steel angles offer exceptional structural support and stability, rendering them an optimal selection for shelving systems. They possess the capability to endure substantial loads and evenly distribute weight, guaranteeing the sturdiness and endurance of the shelving units. Additionally, steel angles are user-friendly and can be customized to suit specific dimensions and designs. They also have resistance against corrosion and can withstand demanding environmental conditions, making them suitable for both indoor and outdoor shelving units. All in all, steel angles provide the strength, versatility, and dependability required for the production of top-notch and enduring shelving units.

- Q: What is the difference between hot-rolled and cold-formed steel angles?

- Hot-rolled steel angles and cold-formed steel angles are both used in various construction and industrial applications, but they differ in their manufacturing processes and resulting characteristics. Hot-rolled steel angles are produced by heating a steel billet or slab above its recrystallization temperature and then passing it through a series of rollers to achieve the desired shape. This process allows for the formation of bends, curves, and other complex angles. Hot rolling also results in a rougher surface finish and a slightly rounded edge, which may be favorable in certain applications. Additionally, hot-rolled steel angles tend to have a wider range of sizes and thicknesses available. On the other hand, cold-formed steel angles are made by bending a flat strip of steel at room temperature using a series of dies and rolls. This process does not involve heating the steel, which maintains its existing physical properties. As a result, cold-formed steel angles have a smoother surface finish and sharper, more defined edges compared to hot-rolled angles. The cold-forming process also allows for tighter tolerances and more precise dimensions. In terms of mechanical properties, hot-rolled steel angles generally have higher tensile strength and yield strength compared to cold-formed angles. This is due to the heat treatment involved in hot rolling, which refines the grain structure and enhances the overall strength of the steel. Cold-formed steel angles, while usually less strong, are often preferred in applications where weight reduction is a priority, as they are generally lighter than their hot-rolled counterparts. In summary, the main differences between hot-rolled and cold-formed steel angles lie in their manufacturing processes, resulting surface finish, dimensional precision, and mechanical properties. The choice between the two depends on the specific requirements and constraints of the project at hand.

- Q: How do steel angles perform in cold weather conditions?

- Steel angles perform well in cold weather conditions due to their high strength and durability. The cold temperature does not significantly affect the performance and structural integrity of steel angles, making them suitable for various applications in cold climates.

- Q: How do you calculate the stability of a steel angle column?

- To calculate the stability of a steel angle column, a few key factors need to be considered. Firstly, the slenderness ratio of the column, which is the ratio of its effective length to its least radius of gyration, must be determined. This can be calculated using the formula: Slenderness ratio = (Effective length of column) / (Least radius of gyration) The least radius of gyration can be calculated using the dimensions of the angle section. For a steel angle, the least radius of gyration can be approximated as the average of the two legs of the angle section divided by the square root of 3. Once the slenderness ratio is determined, it is important to check whether the column is long or short. If the slenderness ratio is less than a critical value, typically around 50 for an angle column, it is considered short and the stability is primarily governed by its strength. In this case, the column can be designed based on its capacity to resist axial compression and flexural buckling. However, if the slenderness ratio exceeds the critical value, the column is considered long and its stability is primarily governed by its ability to resist lateral-torsional buckling. In such cases, additional calculations and considerations must be made to ensure the column's stability. For long angle columns, the critical load at which lateral-torsional buckling may occur can be calculated using various formulas and methods, such as the Euler formula, the Perry-Robertson formula, or finite element analysis. These calculations take into account various parameters such as the column's moment of inertia, modulus of elasticity, and the length of the column. It is important to note that stability calculations for steel angle columns can be complex and require expertise in structural engineering. It is recommended to consult with a qualified professional or refer to relevant design codes and standards, such as the American Institute of Steel Construction (AISC) Manual, for accurate and reliable calculations.

- Q: How do you calculate the moment of inertia of a steel angle?

- In order to determine the moment of inertia of a steel angle, it is necessary to have knowledge of the angle's dimensions and shape. The moment of inertia is a measurement of an object's resistance to rotational changes and is crucial in the fields of engineering and physics. The moment of inertia, designated as I, can be computed using the following equation: I = (b * h^3) / 12 In this equation: - I represents the moment of inertia - b corresponds to the base width of the steel angle - h denotes the height or leg length of the steel angle This equation assumes that the steel angle is a uniform and solid entity. If the steel angle possesses varying dimensions or contains holes, the calculation becomes more intricate and may necessitate additional formulas or numerical methods. It should be emphasized that the moment of inertia is dependent on the axis of rotation. The aforementioned equation calculates the moment of inertia with respect to the centroidal axis, which is the axis that passes through the angle's center of mass. If the moment of inertia needs to be determined for a different axis, the parallel axis theorem or other advanced techniques may need to be employed. In practical applications, it is often beneficial to consult engineering handbooks or reference materials specifically tailored to steel angles. These resources may offer more comprehensive formulas or tables that consider specific design characteristics and dimensions.

Send your message to us

Equal Angle Steel Hot Rolled / Steel Angle Bar /Q235B Angle Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords