Hot Rolled Steel Equal Angle Bar Different Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Angle Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

.

Product Advantages:

OKorder's Angle Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

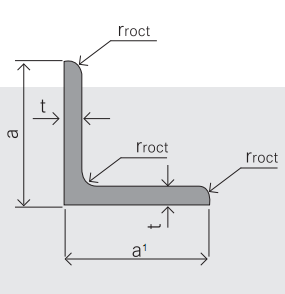

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

4. Chemical data: %

C | Mn | S | P | Si |

0.14-0.22 | 0.30-0.65 | ≤0.050 | ≤0.045 | ≤0.30 |

Packaging & Delivery of Equal Angle

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What is the cost of a steel angle?

- The price of a steel angle may differ based on various factors including its size, grade, thickness, and the supplier or manufacturer chosen. Typically, steel angles are priced either per length or per weight. When determining the cost, it is crucial to take into account the market situation, location, and specific requirements of the desired steel angle. To obtain precise and current pricing details, it is advisable to reach out to local suppliers or manufacturers.

- Q: Can steel angles be used in the construction of parking garages?

- Steel angles can indeed be utilized in the construction of parking garages. These angles are frequently employed in construction due to their robustness, durability, and versatility. They have a wide range of structural applications, including the building of parking garages. Steel angles offer support and reinforcement for crucial elements like beams and columns, as well as for framing and bracing. They play a significant role in establishing the framework for parking garage floors and walls, contributing stability and strength to the structure. Moreover, steel angles can be easily fabricated and tailored to meet the precise design and engineering specifications of a parking garage. All in all, steel angles are a favored choice for constructing parking garages because they can endure heavy loads, resist corrosion, and deliver enduring performance.

- Q: Can steel angles be used for fencing?

- Yes, steel angles can be used for fencing. Steel angles are commonly used in fencing applications due to their strength, durability, and versatility. They provide a sturdy framework for the fence, ensuring stability and security. Steel angles can be easily installed, and their design allows for different fence styles and heights. Additionally, they are resistant to rust and corrosion, making them suitable for outdoor use. Overall, steel angles are a popular choice for fencing projects due to their structural integrity and long-lasting performance.

- Q: What's the size of No. 5 angle iron?

- The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm. It is the number of available models, models of PCT wide edge, such as angle 3#. The model does not mean the size of the different edges and sizes of the same model. Therefore, the width, the edge and the thickness of the angle iron should be filled out in the contract and other documents, so as not to be indicated by the model alone.

- Q: Can steel angles be painted or coated after installation?

- Yes, steel angles can be painted or coated after installation. Painting or coating steel angles after installation can provide additional protection against corrosion and enhance their aesthetic appeal. Prior to painting or coating, it is important to clean and prepare the surface by removing any dirt, rust, or contaminants. This can be done through techniques such as sandblasting, wire brushing, or using chemical cleaners. Once the surface is clean and dry, a suitable primer can be applied to promote adhesion and prevent corrosion. After the primer has dried, a final coat of paint or coating can be applied using a brush, roller, or spray. It is essential to choose a paint or coating that is specifically designed for steel and offers the desired level of protection and durability.

- Q: Can steel angles be used in high-rise or multi-story buildings?

- Yes, steel angles can be used in high-rise or multi-story buildings. Steel angles are commonly used in construction due to their high strength, versatility, and cost-effectiveness. In high-rise buildings, steel angles are often utilized for various structural elements such as beams, columns, and bracing systems. They provide excellent support for transferring loads and forces within the building, contributing to the overall stability and structural integrity. Moreover, steel angles can be easily fabricated and installed, allowing for efficient construction processes in large-scale projects. Therefore, steel angles are widely accepted and utilized in the construction of high-rise or multi-story buildings.

- Q: Are steel angles resistant to chemical corrosion?

- Steel angles have some resistance to chemical corrosion. Although steel is generally strong and durable, it can still corrode in the presence of certain chemicals and corrosive environments. However, steel angles are often treated or coated with protective materials like galvanization, which greatly improves their resistance to chemical corrosion. Galvanized steel angles have a zinc layer on their surface that acts as a barrier against corrosive substances. This coating helps prevent direct contact between the steel and chemicals, reducing the risk of corrosion. It's important to note, though, that the level of resistance may vary depending on the specific chemical, as well as the duration and intensity of exposure. To ensure long-term corrosion resistance, regular maintenance and inspection of steel angles are necessary.

- Q: 304 what does angle iron stand for?

- 304 is a versatile stainless steel which is widely used in the manufacture of equipment and parts requiring good overall performance (corrosion resistance and formability). 304 stainless steel is a brand of stainless steel produced according to the ASTM standard in the United states. 304 chromium 19%, containing nickel 9%.

- Q: What are the maintenance requirements for steel angles?

- The maintenance requirements for steel angles can vary depending on the specific environment and conditions they are exposed to. However, there are some general guidelines to follow to ensure their longevity and functionality. Firstly, it is important to regularly inspect steel angles for any signs of damage or corrosion. This can be done by visually examining the angles and checking for any discoloration, rust, or surface irregularities. If any issues are detected, they should be addressed promptly to prevent further deterioration. Cleaning the steel angles on a regular basis is also essential. This can be done by using a mild detergent or soap solution and a soft cloth or sponge. Avoid using abrasive cleaners or tools that can scratch the surface of the angles. After cleaning, it is important to thoroughly rinse the angles with clean water and dry them completely to prevent moisture buildup. To protect steel angles from corrosion, applying a protective coating or paint is recommended. This can act as a barrier against moisture and other corrosive elements. It is important to choose a coating or paint that is specifically designed for steel and suitable for the intended environment. Regular inspection and touch-up of the coating or paint may be necessary to maintain its effectiveness. Additionally, it is crucial to prevent prolonged exposure to harsh chemicals or corrosive substances that can damage the steel angles. If the angles are installed in an environment where they may come into contact with such substances, it is important to provide appropriate protective measures, such as using chemical-resistant coatings or barriers. Finally, it is advisable to follow any specific maintenance recommendations provided by the manufacturer or supplier of the steel angles. They may have additional guidelines or requirements based on the specific type or grade of steel used. By following these maintenance requirements, steel angles can remain in good condition, retain their structural integrity, and provide long-lasting performance.

- Q: How do you determine the appropriate length of a steel angle for a specific application?

- When determining the appropriate length of a steel angle for a specific application, there are several factors to consider. To begin with, it is necessary to assess the structural requirements of the application. This involves analyzing the loads and forces that the steel angle will experience. It is important to determine the maximum load capacity that the steel angle needs to support and ensure that its length can adequately distribute the load without excessive deflection or failure. Next, the dimensions and layout of the application should be taken into account. The available space should be measured and the fit of the steel angle within the overall structure should be determined. Any constraints, such as adjacent components or obstructions, that may impact the length of the steel angle should also be considered. Furthermore, consulting relevant engineering and construction standards is essential. These codes and guidelines provide recommended design values and specifications for steel angles based on their intended use. They can assist in determining the appropriate length based on the application requirements and the material properties of the steel angle. Additionally, it is important to consider the fabrication and installation process. The manufacturing capabilities and limitations should be evaluated, along with any specific requirements for joining or fastening the steel angle. This will help determine if the desired length is feasible and practical in terms of fabrication and installation methods. Lastly, seeking advice from a structural engineer or a qualified professional in the field is advisable. They can provide expert guidance and calculations based on the specific application, ensuring that the chosen length of the steel angle meets all necessary safety and performance requirements. In conclusion, determining the appropriate length of a steel angle for a specific application involves analyzing the structural requirements, considering the dimensions and layout, referring to relevant standards, evaluating fabrication and installation processes, and seeking professional guidance when required.

Send your message to us

Hot Rolled Steel Equal Angle Bar Different Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches