EPDM Waterproof Membrane1.2mm Weldable

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

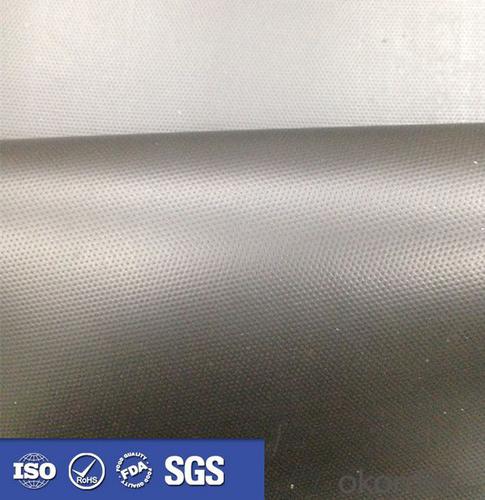

Description Of EPDM Waterproof Membrane1.2mm Weldable:

Self adhesive waterproof rolling material:

thickness:1.2/1.5/2.0mm

length/roll:10/20m

width/roll:1.02m

Low temperature:-15 -20,-30

Main Features of EPDM Waterproof Membrane1.2mm Weldable:

1) High tear

2) High puncturing strength

3) Great temperature resistance.

4) High dimensional stability

Specifications of EPDM Waterproof Membrane1.2mm Weldable:

Material | EPDM Waterproof Membrane1.2mm Weldable |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Waterproof Membrane1.2mm Weldable:

1.It is widely used in civil and industry construction.

2.The waterproof,dampproof of the roofs,basements,toilets etc;

3.And the waterproofing of subway,underground,bridges,car parking,tunnels,reserviors,pool etc.

4.SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions

5.APP specially suitable to areas of high temperature and of strong sunshine.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in fountains or water features?

- Yes, a waterproofing membrane can be used in fountains or water features. Waterproofing membranes are designed to create a barrier that prevents water from seeping through, making them ideal for applications where water containment is essential, such as fountains or water features.

- Q: Can a waterproofing membrane be used for laboratories or research centers?

- Yes, a waterproofing membrane can be used for laboratories or research centers. Waterproofing membranes are effective in preventing water infiltration and can help protect sensitive equipment, materials, and experiments from water damage. They can be applied to various surfaces such as floors, walls, and roofs to create a watertight barrier, ensuring a safe and dry environment for laboratory and research activities.

- Q: Is a waterproofing membrane resistant to impact or abrasion damage?

- Waterproofing membranes are usually designed to resist impact or abrasion damage to some extent, but the degree of resistance can differ based on the membrane's specific type and quality. In general, waterproofing membranes are engineered to endure normal wear and tear, including minor impacts and abrasions. They are typically made from durable materials like modified bitumen, PVC, EPDM, or polyurethane, which offer a certain level of impact and abrasion resistance. These materials are selected for their ability to withstand external forces and safeguard the underlying structure against water infiltration. Although most waterproofing membranes can withstand moderate impacts and abrasions, they may not be completely impervious to severe damage. Heavy impacts or sharp objects have the potential to puncture or tear the membrane, compromising its ability to prevent water penetration. Hence, it is crucial to handle and maintain the membrane with care to reduce the risk of damage. To enhance the impact and abrasion resistance of a waterproofing membrane even further, additional protective layers can be added. For instance, a layer of geotextile fabric or a cementitious coating can be applied over the membrane to provide extra strength and durability. In summary, while a waterproofing membrane is designed to resist impact and abrasion damage, the level of resistance can vary depending on the specific type and quality of the membrane. It is important to choose a high-quality membrane and take appropriate measures to minimize the risk of damage for long-lasting waterproofing performance.

- Q: Can a waterproofing membrane be installed by a DIYer?

- Yes, a waterproofing membrane can be installed by a DIYer. However, it is essential to follow the manufacturer's instructions carefully and have a basic understanding of the process. Additionally, the DIYer should possess the necessary skills and tools required for the installation. It is advisable to conduct thorough research and consider the complexity of the project before attempting it as improper installation can lead to ineffective waterproofing.

- Q: Can a waterproofing membrane be applied on top of existing surfaces?

- Yes, a waterproofing membrane can be applied on top of existing surfaces. However, it is important to ensure that the existing surface is clean, dry, and free from any contaminants or loose materials before applying the membrane. Additionally, proper surface preparation and application techniques should be followed to ensure the effectiveness and longevity of the waterproofing system.

- Q: Are waterproofing membranes suitable for indoor applications?

- Yes, waterproofing membranes are suitable for indoor applications. They are commonly used in areas such as bathrooms, basements, and kitchens to prevent water damage and moisture penetration. Waterproofing membranes provide an effective barrier against water and can help protect the structural integrity of buildings in indoor environments.

- Q: Are waterproofing membranes resistant to alkali exposure?

- Yes, waterproofing membranes are typically resistant to alkali exposure. These membranes are designed to provide a protective barrier against water and other harmful substances, including alkalis. They are made from materials such as rubber, bitumen, or polymer-based compounds that have a high resistance to alkali. This ensures that the membrane remains intact and effective even when exposed to alkali-rich environments, such as concrete or cement surfaces. Additionally, these membranes undergo rigorous testing and are specifically manufactured to withstand alkali exposure, making them a reliable solution for waterproofing applications in various industries, including construction and infrastructure.

- Q: How does a waterproofing membrane handle water infiltration through cracks or gaps?

- A waterproofing membrane is designed to handle water infiltration through cracks or gaps by forming a continuous barrier that prevents water from seeping through. The membrane is typically made of a durable and flexible material, such as rubber, PVC, or modified bitumen, which is able to withstand the movement and expansion of the underlying structure. When water encounters a crack or gap in the surface, the membrane acts as a sealant, preventing the water from penetrating further. The material used in the membrane is impermeable to water, meaning it does not allow water molecules to pass through its surface. Furthermore, the membrane is installed in such a way that it covers the entire surface area, including any cracks or gaps that may be present. This ensures that there are no weak points in the waterproofing system where water can infiltrate. In addition to its impermeability, the membrane is also designed to be flexible. This flexibility allows it to accommodate any movement or shifting of the underlying structure, without compromising its waterproofing capabilities. This is particularly important in areas where cracks or gaps may occur due to the natural settling or movement of the building. Overall, a waterproofing membrane effectively handles water infiltration through cracks or gaps by providing a continuous, impermeable barrier that prevents water from entering the structure. It is a reliable solution for protecting buildings and structures from water damage and maintaining their integrity over time.

- Q: Can a waterproofing membrane be applied to existing structures or only during construction?

- Yes, a waterproofing membrane can be applied to existing structures as well as during construction. The application of a waterproofing membrane is not limited to new constructions. In fact, retrofitting existing structures with a waterproofing membrane is a common practice to prevent water infiltration and protect the building from moisture-related damages. This can be done by preparing the surface, cleaning and repairing any existing damage or cracks, and then applying the waterproofing membrane according to the manufacturer's instructions. It is important to note that the suitability and compatibility of the waterproofing membrane with the existing structure should be assessed by a professional to ensure its effectiveness and longevity.

- Q: Can a waterproofing membrane be used in cold climates?

- Yes, a waterproofing membrane can be used in cold climates. In fact, many waterproofing membranes are specifically designed to withstand extreme temperatures, including freezing conditions. These membranes are engineered to remain flexible and durable even in cold environments, ensuring effective protection against water infiltration and damage.

Send your message to us

EPDM Waterproof Membrane1.2mm Weldable

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords