EPDM Membrane Weldable for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 90000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Membrane Weldable for Waterproof System

Description Of EPDM Membrane Weldable:

1. EPDM membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Membrane Weldable:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Membrane Weldable:

Material | Ternary Ethylene-Propylene rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Membrane Weldable:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

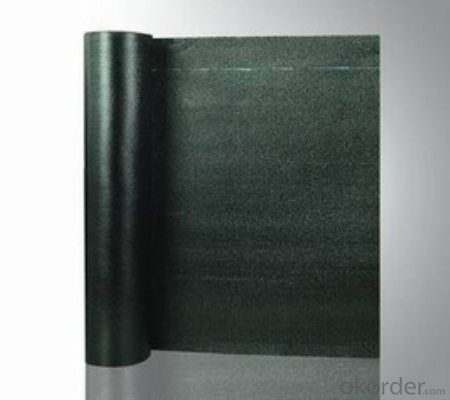

IMages of EPDM Weldable Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Are waterproofing membranes resistant to high temperatures?

- Waterproofing membranes can vary in their resistance to high temperatures depending on the specific material used. Some waterproofing membranes are designed to withstand high temperatures without losing their effectiveness or integrity. These membranes are often made from materials such as modified bitumen or synthetic rubber, which have high temperature resistance properties. However, it is important to note that not all waterproofing membranes are resistant to high temperatures. Some membranes made from PVC or other thermoplastic materials may have limitations when exposed to extreme heat. Therefore, it is crucial to consult the manufacturer's specifications and guidelines to ensure that the chosen waterproofing membrane is suitable for the intended application and can withstand the anticipated temperature conditions.

- Q: Can a waterproofing membrane be used on terracotta surfaces?

- Terracotta surfaces can benefit from the use of a waterproofing membrane. Due to its porous nature, terracotta absorbs water and can suffer damage and deterioration as a result. To prevent such issues, applying a waterproofing membrane creates a barrier that stops water from penetrating and safeguards the material against moisture-related problems. Acting as a protective layer, the membrane keeps the terracotta surface dry and prevents water from seeping through. This is especially advantageous in areas with high moisture levels or where terracotta is exposed to water, like bathrooms, kitchens, or outdoor installations. To ensure compatibility and effectiveness, it is crucial to select a waterproofing membrane specifically designed for terracotta surfaces. Additionally, following proper surface preparation and application techniques is essential for achieving optimal results.

- Q: Are waterproofing membranes resistant to thermal cycling?

- Yes, waterproofing membranes are generally resistant to thermal cycling. These membranes are designed to withstand changes in temperature without losing their effectiveness. Thermal cycling refers to the repeated expansion and contraction of materials due to temperature fluctuations. Waterproofing membranes are engineered to have excellent dimensional stability, which means they can expand and contract with minimal deformation. This resistance to thermal cycling ensures that the membranes maintain their integrity and prevent water penetration, even in extreme temperature conditions. However, it is important to note that the specific resistance to thermal cycling can vary depending on the type and quality of the waterproofing membrane used.

- Q: Can a waterproofing membrane be used in food processing or pharmaceutical facilities?

- Yes, a waterproofing membrane can be used in food processing or pharmaceutical facilities. Waterproofing membranes are designed to provide a protective barrier against moisture, which is beneficial in environments where hygiene and cleanliness are paramount, such as food processing or pharmaceutical facilities. By preventing water penetration, these membranes help maintain a dry, clean, and hygienic environment, ensuring the safety and integrity of the products being processed or manufactured.

- Q: Can a waterproofing membrane be used on tunnels with lighting systems?

- Indeed, tunnels with lighting systems can benefit from the utilization of a waterproofing membrane. In reality, it is frequently imperative to employ waterproofing membranes in tunnels to safeguard the structure against water infiltration. These membranes are specifically engineered to establish a barrier, preventing water from permeating the tunnel and inducing harm. Typically, they are administered to the tunnel's walls, floors, and ceilings, and can be seamlessly integrated with lighting systems. The application of a waterproofing membrane will not compromise the functionality or safety of the lighting system, but instead, guarantee that the tunnel remains impervious to water and shielded from issues arising from moisture.

- Q: Can a waterproofing membrane be used on precast metal surfaces?

- Yes, a waterproofing membrane can be used on precast metal surfaces. The membrane acts as a protective barrier, preventing water from seeping through the metal and causing damage. It helps to maintain the integrity and longevity of the precast metal surfaces by keeping them dry and free from moisture-related issues.

- Q: Can a waterproofing membrane be used on both interior and exterior walls?

- Yes, a waterproofing membrane can be used on both interior and exterior walls. The membrane helps prevent water penetration, providing protection against moisture for both sides of the wall.

- Q: Can a waterproofing membrane be used for planter boxes or green roofs?

- Certainly, planter boxes or green roofs can benefit from the utilization of a waterproofing membrane. It is strongly advised to implement a waterproofing membrane in these scenarios in order to avoid any water seepage or harm to the underlying structure. Essentially acting as a safeguard, the waterproofing membrane serves to prevent water infiltration into the planter boxes or green roofs, therefore preventing potential complications like decay, mold, or structural deterioration. By skillfully sealing the area, the waterproofing membrane guarantees that the water remains within the designated area, which in turn fosters robust plant growth and safeguards the structural stability.

- Q: Can a waterproofing membrane withstand heavy rain or water pressure?

- A waterproofing membrane is specifically designed to endure heavy rain or water pressure. Its main purpose is to establish a barrier that obstructs water from infiltrating a structure or surface. Generally, these membranes are composed of materials like rubberized asphalt, PVC, or EPDM (ethylene propylene diene monomer), which possess a remarkable resistance against water and can effectively endure heavy rain or water pressure. Furthermore, these membranes are frequently fortified with layers or fabrics to offer additional strength and durability. Consequently, when accurately installed and regularly maintained, a waterproofing membrane can effectively endure heavy rain or water pressure, ensuring dependable protection against water damage.

- Q: Can a waterproofing membrane be used for a planter box waterproofing?

- Yes, a waterproofing membrane can be used for planter box waterproofing. A waterproofing membrane is designed to create a barrier against water and moisture, preventing it from seeping through the surface it is applied to. This makes it an ideal choice for planter box waterproofing, as it helps to protect the structure of the planter box and prevent water damage. The membrane can be applied to the interior of the box, creating a watertight seal that prevents water from leaking out or causing damage to the surrounding surfaces. Additionally, a waterproofing membrane can also help to extend the lifespan of the planter box by preventing the growth of mold or mildew, which can be caused by excess moisture. Overall, using a waterproofing membrane for planter box waterproofing is a practical and effective solution to ensure the longevity and durability of the planter box.

Send your message to us

EPDM Membrane Weldable for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 90000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords