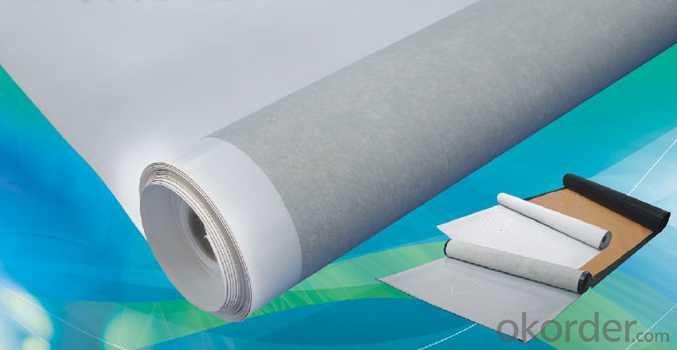

EPDM Waterproof Membrane for Underground Proof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product features:

The physical and mechanical properties of stability, durability and anti ageing capacity is good, its oil and solvent resistance and general-purpose chloroprene rubber be roughly the same.

1 Good heat resistance, cold resistance, can be in (-60-150 C) within the scope of use.

2 Extension and rate very high tear strength, shrinkage cracking of buildings or a strong ability to adapt.

3 The proportion of light (0.90~0.97), the appearance of uniform quality, has good flexibility and elasticity.

4 Good weldability, materials can be directly welded, is conducive to ensure weld quality. After welding to form an integral waterproof layer.

5 Good dimensional stability, heat shrinkage is small, the deformation is small, keep a good state during construction.

6 Environmental protection type. Does not produce harmful substances in the production, construction and use of the process, and can be recycled, does not produce construction waste.

Application range:

Applicable to all kinds of roofing, basement, tunnel, building waterproof engineering; civil and industrial building roofs and underground engineering, municipal, bridges, storage tank,

Waterproof subway, tunnel, dam engineering, especially suitable for durability, corrosion resistance requirements and easy deformation of the key waterproof engineering.

Specification of EPDM Waterproofing Membrane

1 | Breaking Tensile Strength(Room temperature) | Mpa | ≥7.5 | |

2 | Breaking Tensile Strength 60℃ | Mpa | ≥2.3 | |

3 | Breaking Elongation(Room temperature) | % | ≥450 | |

4 | Breaking Elongation(-20℃) | % | ≥200 | |

5 | Tearing strength | KN/m | ≥25 | |

6 | Impermeability, 30min no leakage | -- | 0.3Mpa no leakage | |

7 | Low temperature bending | ℃ | ≤ -40 | |

8 | Heating shrinking | Extension | mm | ≤2 |

Shrink | mm | ≤4 | ||

9 | Heat resistance (80℃x168h) | Tensile strength | % | ≥80 |

Elongation retentions | % | ≥70 | ||

10 | Alkaline resistance, Ca(OH)2 solution, room temperature x168h | Tensile strength | % | ≥80 |

Elongation retentions | % | ≥80 | ||

11 | Ozone aging(40℃x168h) | Elongation40%, 500x10-2 | -- | Non-crack |

12 | Synthetic aging | Tensile strength | % | ≥80 |

Elongation retentions | % | ≥70 | ||

FAQ of EPDM Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for retaining walls?

- Yes, a waterproofing membrane can be used for retaining walls. Retaining walls are structures designed to hold back soil or water, and it is essential to prevent water penetration to avoid potential damage or structural failure. Waterproofing membranes are commonly used to provide a barrier against water infiltration, thereby protecting the retaining wall and ensuring its stability over time. These membranes are typically made of materials like rubber, PVC, or bituminous compounds, and they are installed on the inner side of the retaining wall to prevent water from seeping through. Additionally, some waterproofing membranes also offer additional benefits such as resistance to root penetration, UV protection, and flexibility to accommodate movement in the retaining wall. However, it is important to note that the specific type of waterproofing membrane used should be selected based on factors such as the type of retaining wall, the level of water pressure, and local climate conditions. Consulting with a professional engineer or contractor is recommended to ensure the appropriate waterproofing solution for your particular retaining wall project.

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Theaters and concert halls can benefit greatly from the use of waterproofing membranes. These membranes are commonly employed in construction projects to safeguard buildings against water damage by preventing water infiltration. They are applied to various surfaces, including walls, floors, and roofs, creating a barrier that stops water from seeping through. In the case of theaters and concert halls, where the protection of the building structure and equipment is of utmost importance, waterproofing membranes can be extremely advantageous. They play a crucial role in preventing water damage to delicate equipment like audiovisual systems, lighting fixtures, and musical instruments. Furthermore, these membranes ensure a dry and comfortable environment for both performers and audience members by preventing water leakage and moisture buildup. In conclusion, the use of a waterproofing membrane in theaters or concert halls guarantees the longevity and functionality of the building, creating a safe and enjoyable experience for all involved.

- Q: Can a waterproofing membrane be used for water features or fountains?

- Indeed, a waterproofing membrane is suitable for water features or fountains. Specifically engineered to obstruct water infiltration, these membranes are an excellent option for water-related purposes. They establish a barricade that confines water within the intended space, warding off any leaks or seepage. Moreover, certain waterproofing membranes possess supplementary attributes, such as UV ray and chemical resistance, which prove advantageous for water features or fountains exposed to sunlight or treated with water treatment chemicals. In summary, the utilization of a waterproofing membrane guarantees the preservation of water features or fountains' impermeability and functionality.

- Q: Can a waterproofing membrane be applied over existing coatings or sealants?

- Indeed, existing coatings or sealants can be overlaid with a waterproofing membrane. Nevertheless, it is crucial to adequately prepare the surface and eliminate any flaky or impaired coatings or sealants prior to applying the waterproofing membrane. This will guarantee optimal adhesion and efficiency of the membrane. Furthermore, it is advisable to refer to the manufacturer's instructions or acquire expert guidance to guarantee compatibility between the existing coatings or sealants and the waterproofing membrane.

- Q: Can a waterproofing membrane be used on sloped roofs?

- Yes, a waterproofing membrane can be used on sloped roofs. Waterproofing membranes are designed to provide a protective barrier against water penetration, and their flexibility allows them to conform to the shape of sloped roofs effectively. This helps prevent water from seeping into the structure and causing damage.

- Q: Can a waterproofing membrane be used for water fountains or decorative features?

- Water fountains and decorative features can benefit from the use of a waterproofing membrane. These membranes are specifically designed to create a protective barrier against water penetration and can be applied to various surfaces, including those found in water fountains and decorative features. The materials used to make these membranes, such as rubber, bitumen, or liquid-applied coatings, possess excellent waterproofing properties. By applying a waterproofing membrane, you can effectively prevent water from infiltrating the underlying structure and causing damage. This is particularly crucial for water fountains and decorative features, as they are constantly exposed to water. Moreover, waterproofing membranes can also play a role in averting leaks, cracks, and other potential issues that may arise from water exposure, thereby extending the lifespan of the fountain or decorative feature.

- Q: Can a waterproofing membrane be used for a residential building facade?

- A residential building facade can utilize a waterproofing membrane. This material is applied to the exterior surface of the building to prevent water from penetrating and damaging the structure due to moisture. It proves particularly beneficial for residential buildings that are exposed to different weather conditions. The utilization of a waterproofing membrane for a residential building facade offers several advantages. Firstly, it prevents water from seeping through the facade and causing harm to the interior walls, insulation, and other building materials. This ensures a dry and comfortable living environment inside the house. Moreover, a waterproofing membrane extends the lifespan of the building facade by acting as a protective barrier against moisture and water-related issues like mold, mildew growth, and efflorescence. This condition causes discoloration and deterioration of the facade over time due to mineral deposits from water. Furthermore, this type of membrane enhances the energy efficiency of a residential building. It achieves this by preventing water infiltration, thereby maintaining proper insulation and reducing air leakage. This, in turn, reduces the energy required for heating or cooling the building. However, it is crucial to select the appropriate waterproofing membrane for the specific requirements of the residential building facade. There are several options available, including liquid-applied membranes, sheet membranes, and spray-applied membranes. Each option has its own advantages and limitations. Therefore, consulting a professional waterproofing contractor or architect is advisable to determine the most suitable membrane system for the project. Additionally, proper installation and regular maintenance are essential to ensure the effectiveness and longevity of the waterproofing membrane on the residential building facade.

- Q: Are waterproofing membranes resistant to saltwater corrosion?

- Yes, waterproofing membranes are generally resistant to saltwater corrosion. They are specifically designed to provide a protective barrier against water and moisture, including exposure to saltwater. These membranes are typically made from materials that resist corrosion, such as synthetic polymers or bitumen, which can withstand the corrosive effects of saltwater. Additionally, waterproofing membranes are often reinforced with additives or coatings that enhance their resistance to corrosion. However, it is important to note that the level of resistance may vary depending on the specific type and quality of the membrane used. It is advisable to consult with professionals or manufacturers to ensure that the chosen waterproofing membrane is suitable for saltwater environments.

- Q: How does a waterproofing membrane handle water infiltration through cracks or gaps?

- A waterproofing membrane is designed to handle water infiltration through cracks or gaps by forming a continuous barrier that prevents water from seeping through. The membrane is typically made of a durable and flexible material, such as rubber, PVC, or modified bitumen, which is able to withstand the movement and expansion of the underlying structure. When water encounters a crack or gap in the surface, the membrane acts as a sealant, preventing the water from penetrating further. The material used in the membrane is impermeable to water, meaning it does not allow water molecules to pass through its surface. Furthermore, the membrane is installed in such a way that it covers the entire surface area, including any cracks or gaps that may be present. This ensures that there are no weak points in the waterproofing system where water can infiltrate. In addition to its impermeability, the membrane is also designed to be flexible. This flexibility allows it to accommodate any movement or shifting of the underlying structure, without compromising its waterproofing capabilities. This is particularly important in areas where cracks or gaps may occur due to the natural settling or movement of the building. Overall, a waterproofing membrane effectively handles water infiltration through cracks or gaps by providing a continuous, impermeable barrier that prevents water from entering the structure. It is a reliable solution for protecting buildings and structures from water damage and maintaining their integrity over time.

- Q: Can a waterproofing membrane be used on gypsum block surfaces?

- Gypsum block surfaces can benefit from the use of a waterproofing membrane. These surfaces are porous and can absorb moisture, making them naturally non-waterproof. By applying a waterproofing membrane, the infiltration of water, moisture damage, and mold growth on gypsum block surfaces can be prevented. The membrane acts as a barrier, repelling water and keeping it from penetrating the material. However, it is crucial to choose a suitable waterproofing membrane that is specifically designed for use on gypsum blocks and compatible with the particular type of gypsum block being treated. Moreover, to ensure the effectiveness and durability of the waterproofing membrane, proper surface preparation and application techniques must be followed.

Send your message to us

EPDM Waterproof Membrane for Underground Proof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords