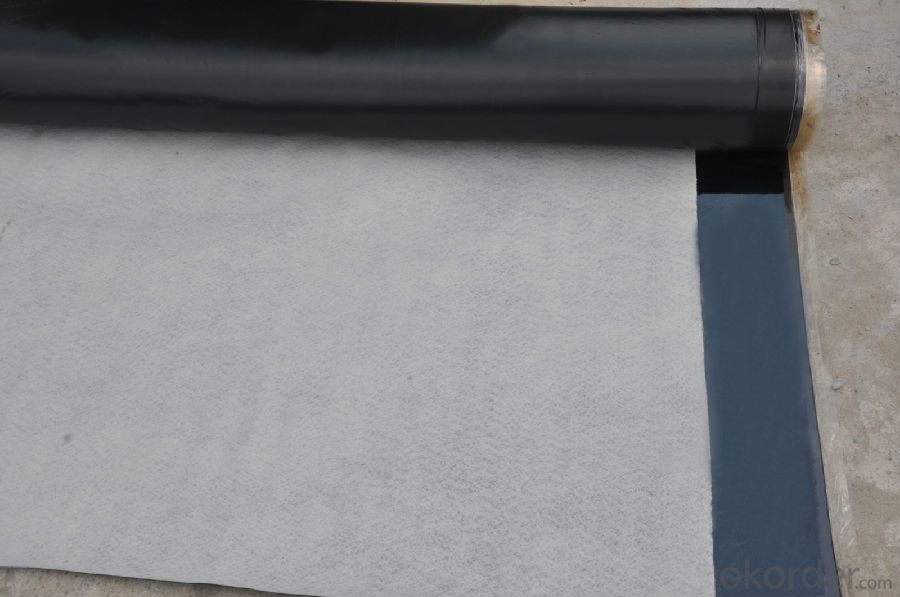

EPDM Rubber Waterproofing Membrane Underground

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for EPDM Waterproofing Membrane:

Waterproof membrane for roof adopt the international advanced level cold feed extrusion continuous vulcanization process for the integration of production equipment and technology so that the system density of products is better and the products have no bubble sooth surface, no performance difference between vertical and horizontal.

Characteristic of EPDM Waterproofing Membrane:

· with adhesive tape on the overlap for the sealing of junction,convention for application.

· Excellent weather resistance, corrosion resistance, anti-aging, antioxidant.

· Excellent waterproofing performance and encase nail holes.

· Good permeability, can be in damp base surface construction, make the maintenance structure internal water vapor rapidly eduction, avoid effectively mould and condensing formation

Excellent tensile strength and elongation.

· large Surface friction, grass-roots closely.

no smell,no taste,accord with environmental protection requirements.

Specification of EPDM Waterproofing Membrane:

No. | Item | Unit | Standard Request | |

1 | Variation in Dimension | Thickness | % | ±10 |

Width | % | ±1 | ||

Length | % | No Negative Value | ||

2 | Tensile Strength at Break(Normal Temperature) | Mpa | ≥7.5 | |

Tensile Strength at Break(60ºC) | Mpa | ≥2.3 | ||

3 | Elongation at Break(Normal Temperature) | % | ≥450 | |

Elongation at Break(-20ºC) | % | ≥200 | ||

4 | Tearing Strength | KN/m | ≥25 | |

5 | Water Impermeability(30min) | * | 0.3Mpa Impermeability | |

6 | Bend Temperature | ºC | ≤-40 | |

7 | Heating Expansion/Shrinkage | Expansion | mm | ≤2 |

Shrinkage | mm | ≤4 | ||

8 | Hot Air Aging 80ºC x168h | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥70 | ||

9 | Property of Anti Alkali 10% Ca(OH)²x 168h normal temperature | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥80 | ||

10 | Elongation 40%,500x102 | * | No Crack | |

11 | Artificial Aging | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥70 | ||

Appearance of 100% elongation | * | No Crack | ||

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Are there different waterproofing membrane options for above-ground and below-ground applications?

- Yes, there are different waterproofing membrane options available for above-ground and below-ground applications. Above-ground applications typically involve waterproofing structures such as roofs, balconies, or walls. For these applications, commonly used waterproofing membrane options include liquid-applied membranes, sheet membranes, and polyurethane membranes. These membranes are designed to withstand exposure to weather elements such as UV rays, temperature changes, and foot traffic. On the other hand, below-ground applications involve waterproofing structures like basements, foundations, or tunnels. Below-ground waterproofing membranes are specifically designed to withstand hydrostatic pressure from the surrounding soil and groundwater. These membranes are typically thicker and more durable than above-ground membranes. Commonly used below-ground waterproofing options include bituminous membranes, bentonite clay membranes, and composite membranes. It is important to choose the right waterproofing membrane for each specific application as the requirements and challenges can vary. Consulting with a waterproofing professional or engineer can help determine the most suitable membrane option for both above-ground and below-ground applications.

- Q: Are waterproofing membranes suitable for wastewater treatment plants?

- Yes, waterproofing membranes are suitable for wastewater treatment plants. Wastewater treatment plants deal with the treatment and processing of wastewater, which contains a variety of chemicals, contaminants, and bacteria. These substances can be highly corrosive and can cause damage to the infrastructure of the plant if not properly protected. Waterproofing membranes provide an effective barrier against water and chemical penetration, preventing leaks, seepage, and corrosion. They can be applied to various areas of the plant, including tanks, basins, pipelines, and concrete structures. Additionally, waterproofing membranes are durable, long-lasting, and can withstand the harsh conditions and chemicals present in wastewater treatment plants. Therefore, using waterproofing membranes in wastewater treatment plants is a recommended practice to ensure the integrity, longevity, and efficiency of the infrastructure.

- Q: Can a waterproofing membrane be used in commercial construction?

- Yes, a waterproofing membrane can definitely be used in commercial construction. In fact, it is often a critical component of commercial building projects to protect structures from water intrusion and potential damage. Waterproofing membranes are designed to create a barrier against moisture and can be applied to various areas such as roofs, basements, foundations, and walls, ensuring a watertight and durable building envelope.

- Q: Can a waterproofing membrane be used on green roofs?

- Certainly, green roofs can benefit greatly from the utilization of a waterproofing membrane. In fact, it serves as a crucial element within the green roof system. The concept of a green roof revolves around the presence of vegetation and soil atop a waterproof layer, which effectively prevents any water infiltration into the underlying structure. By acting as a barrier, the waterproofing membrane safeguards both the roof and the building from potential moisture-related harm. Its primary function is to ensure proper drainage, thereby averting any leaks or structural complications. However, it is imperative to select a waterproofing membrane that is specifically engineered for green roof applications, as it must withstand the unique challenges posed by a green roof environment, such as root penetration and continuous exposure to moisture.

- Q: Can a waterproofing membrane be used for data centers?

- Using a waterproofing membrane in data centers is possible. The main purpose of a waterproofing membrane is to stop water from getting in, which is very important for safeguarding delicate equipment and crucial data in a data center. Water damage can lead to expensive periods of inactivity and data loss, so it is crucial to have dependable waterproofing measures in place. By applying a waterproofing membrane to the walls, floors, and ceilings of a data center, a barrier can be created to prevent water leaks and the buildup of moisture. This ensures that a controlled and dry environment is maintained, guaranteeing the safety and functionality of the data center's infrastructure and equipment. Furthermore, certain waterproofing membranes also provide insulation properties, further improving the protection and energy efficiency of the data center.

- Q: Can a waterproofing membrane be used in interior or exterior applications?

- A waterproofing membrane can be utilized in both interior and exterior scenarios. When used indoors, such as in basements or bathrooms, the membrane can be applied to walls or floors to effectively prevent water or moisture infiltration. This safeguard shields the underlying structure from potential harm caused by water intrusion. For exterior applications, the waterproofing membrane can be employed on the outer walls or foundations of a building to effectively repel water. This becomes particularly crucial in regions with heavy rainfall or high water tables. By creating a barrier against water, the membrane effectively maintains a dry and water-free interior environment for the building. In conclusion, the utilization of a waterproofing membrane in both interior and exterior contexts is absolutely necessary in order to ensure the longevity and durability of a structure by effectively safeguarding it against water-related issues.

- Q: Can a waterproofing membrane be used on precast stone block surfaces?

- Yes, a waterproofing membrane can be used on precast stone block surfaces. A waterproofing membrane is designed to provide a protective barrier against water infiltration, and it can be applied to various surfaces, including precast stone blocks, to prevent water damage and ensure the longevity of the structure.

- Q: Can a waterproofing membrane be used on terraces or patios?

- Yes, a waterproofing membrane can be used on terraces or patios to prevent water penetration and protect the underlying structure from moisture damage.

- Q: Can a waterproofing membrane be used for water tanks?

- Yes, a waterproofing membrane can be used for water tanks. Waterproofing membranes are specifically designed to prevent the passage of water and can effectively seal water tanks, ensuring that they remain watertight. These membranes are commonly made from materials such as bitumen, PVC, or EPDM, which provide excellent resistance to water and are capable of withstanding the harsh conditions often found in water tanks. Additionally, waterproofing membranes can be applied to various surfaces, including concrete, metal, and masonry, making them versatile and suitable for different types of water tanks. Overall, using a waterproofing membrane is a reliable solution for ensuring the integrity and longevity of water tanks by preventing water leakage and protecting the surrounding environment from potential water damage.

- Q: Are waterproofing membranes resistant to hydrostatic pressure?

- Yes, waterproofing membranes are designed to be resistant to hydrostatic pressure. Hydrostatic pressure refers to the pressure exerted by water when it is at rest. When a building is exposed to water from the ground, such as in basements or foundations, hydrostatic pressure can become a significant concern, as it can cause water to seep through the walls or floors. Waterproofing membranes are specifically engineered to withstand and resist the pressure exerted by water, ensuring that it does not penetrate into the building structure. These membranes are typically made from materials such as bitumen, rubberized asphalt, or synthetic polymers, which have excellent water resistance properties. Moreover, waterproofing membranes are designed to create a continuous barrier against water, preventing any potential leaks or seepage. They are applied in multiple layers, ensuring a strong and durable barrier that can withstand the high pressure exerted by water. It is important to note that the resistance to hydrostatic pressure may vary depending on the type and quality of the waterproofing membrane used. Therefore, it is crucial to choose a high-quality membrane and ensure proper installation to maximize its effectiveness in resisting hydrostatic pressure.

Send your message to us

EPDM Rubber Waterproofing Membrane Underground

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords