EPDM Rubber Waterproof Membrane for Ponds with 1.0mm/1.2mm/1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of EPDM Waterproof Membrane:

1. the excellent anti-aging, in the long term light, humidity, cold use of the natural environment, small changes in physical properties, used in the temperature:From -50 degree Celsius to +80degree Celsious

2. EPDM waterproof membrane production vulcanized/sulfuretted EPDM rubber roofing waterproof membrane

Main Features of EPDM Waterproof Membrane:

1). Excellent weather-ability, durability and size stability

2) Good adaptability to high and low temperature, UV resistant and anti-corrosion

3) High tensile strength and good elongation, accommodating to structure movement

4) Easy installation, solid joint, and no environmental pollution

5) Good rooting penetration resistance

6) Service life up to 50 years

Specifications of EPDM Waterproof Membrane:

ITEM | STANDARO REQUEST | |

Tensile strength at breaking,normal temperature,Mpa | ≥7.5 | |

Elongation at breaking, % | ≥450 | |

Tearing strenght,KN/m | ≥25 | |

Bending at low temperature | ≤-40°C | |

Water impermeability,0.1Mpa×30min | Impermeability | |

Hot air aging 80°C×168h | Unchanging of tensile strength at breaking,% | ≥80 |

Unchanging of elongation at breaking,% | ≥70 | |

Appearance of 100% elongation | No crack | |

Property of anti alkali 10% Ca(OH)2×168h normal temperature | ≥80 | |

≥80 | ||

Applications of EPDM Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

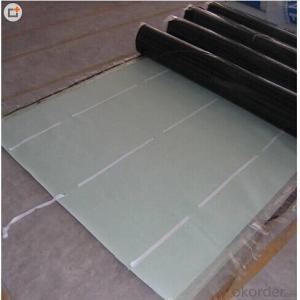

IMages of EPDM Rubber Waterproof Membrane:

FAQ:

Q1.:What are we supplying?

A1:We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

Q2: How Many years experience do we have?

A2:We have exported to more than 20 countries in the past 15 years.

Q3.:Do you provide samples for us?

A3:Yes,We will provide samples for free.Waiting for your your good news.

- Q: Can a waterproofing membrane be used in renovation projects?

- Yes, a waterproofing membrane can definitely be used in renovation projects. In fact, it is often a crucial component in ensuring the longevity and durability of the renovated structure. Waterproofing membranes are designed to create a barrier against water infiltration, protecting the building from potential water damage and leaks. During renovation projects, it is common to encounter areas where water resistance is important, such as basements, bathrooms, showers, balconies, and roofs. Applying a waterproofing membrane in these areas can help prevent moisture problems, mold growth, and structural damage caused by water seepage. Furthermore, waterproofing membranes can be used in various types of renovation projects, including residential, commercial, and industrial. Whether it is a small-scale bathroom renovation or a large-scale commercial building refurbishment, utilizing a waterproofing membrane ensures enhanced protection against water-related issues. Moreover, waterproofing membranes come in different forms, such as liquid-applied membranes, sheet membranes, and cementitious coatings. These options provide flexibility in choosing the most suitable membrane for a specific renovation project, considering factors like budget, substrate, and desired level of waterproofing. In summary, a waterproofing membrane is an essential element in renovation projects, as it helps safeguard against water damage and ensures the longevity of the renovated structure. By using a waterproofing membrane, owners can have peace of mind knowing their renovated space is well-protected against potential water-related issues.

- Q: Can a waterproofing membrane be used in areas with extreme weather conditions, such as hurricanes or snowstorms?

- Areas with extreme weather conditions, such as hurricanes or snowstorms, can benefit from the use of a waterproofing membrane. These membranes are designed to create a protective barrier against water infiltration and can withstand various weather conditions effectively. They are made from moisture-resistant materials and can be installed in roofs, basements, or foundations. In regions prone to hurricanes, waterproofing membranes play a crucial role in preventing water damage. They create a barrier that keeps water out, even during heavy rainfall or storm surges. These membranes are often reinforced and possess high tensile strength to withstand the strong winds and pressure associated with hurricanes. Similarly, in areas experiencing heavy snowstorms, waterproofing membranes are valuable in preventing water intrusion caused by melting snow or ice dams. They are designed to be flexible and resistant to extreme temperatures, ensuring their integrity and leak prevention in freezing conditions. However, it is essential to select the appropriate type of waterproofing membrane for the specific weather conditions in the area. Different membranes offer varying levels of resistance to extreme weather, so consulting with a professional is advisable to determine the most suitable membrane for the climate and weather patterns. Additionally, proper installation and regular maintenance are crucial to ensure the longevity and effectiveness of the waterproofing system in extreme weather conditions.

- Q: Does a waterproofing membrane require a primer before application?

- Yes, a waterproofing membrane typically requires a primer before application. A primer helps to enhance the adhesion of the membrane to the substrate and ensures a proper bond between the two. It also helps to seal the surface, preventing any moisture or contaminants from compromising the effectiveness of the waterproofing system. Using a primer before applying the waterproofing membrane is important for achieving a durable and long-lasting waterproofing solution.

- Q: Can a waterproofing membrane be applied to horizontal surfaces?

- Yes, a waterproofing membrane can be applied to horizontal surfaces.

- Q: Can waterproofing membranes be used on retaining walls?

- Yes, waterproofing membranes can be used on retaining walls. Waterproofing membranes are commonly used on retaining walls to prevent water infiltration and protect the structure from moisture-related issues such as seepage, efflorescence, and cracking. These membranes act as a barrier that prevents water from penetrating the retaining wall and causing damage. They are typically installed on the exterior side of the retaining wall, providing an additional layer of protection against water intrusion. Waterproofing membranes come in various forms, such as sheet membranes, liquid-applied membranes, and cementitious coatings, and can be chosen based on the specific needs and requirements of the retaining wall.

- Q: Can a waterproofing membrane be used in interior or exterior applications?

- A waterproofing membrane can be utilized in both interior and exterior scenarios. When used indoors, such as in basements or bathrooms, the membrane can be applied to walls or floors to effectively prevent water or moisture infiltration. This safeguard shields the underlying structure from potential harm caused by water intrusion. For exterior applications, the waterproofing membrane can be employed on the outer walls or foundations of a building to effectively repel water. This becomes particularly crucial in regions with heavy rainfall or high water tables. By creating a barrier against water, the membrane effectively maintains a dry and water-free interior environment for the building. In conclusion, the utilization of a waterproofing membrane in both interior and exterior contexts is absolutely necessary in order to ensure the longevity and durability of a structure by effectively safeguarding it against water-related issues.

- Q: Can a waterproofing membrane be used for loading dock levelers and pit walls?

- Yes, a waterproofing membrane can be used for loading dock levelers and pit walls. Waterproofing membranes provide a protective barrier against moisture and can help prevent water damage and leakage in these areas.

- Q: Can a waterproofing membrane be used for a garden pond liner?

- Yes, a waterproofing membrane can be used as a garden pond liner. Waterproofing membranes are designed to prevent water penetration, making them an effective option for creating a watertight barrier in a garden pond.

- Q: Can a waterproofing membrane be used in shower pans?

- Yes, a waterproofing membrane can be used in shower pans. In fact, it is highly recommended to use a waterproofing membrane in shower pans to prevent any water leakage or damage to the underlying structure. A waterproofing membrane acts as a barrier, preventing water from seeping through the shower pan and into the subfloor or surrounding walls. This helps to maintain the integrity and longevity of the shower pan and the overall shower system. Additionally, a waterproofing membrane can also protect against mold and mildew growth, ensuring a safe and hygienic environment. Therefore, using a waterproofing membrane in shower pans is an essential step in ensuring a durable and water-resistant shower installation.

- Q: Can a waterproofing membrane be used for swimming pool decks or patios?

- Yes, a waterproofing membrane can be used for swimming pool decks or patios.

Send your message to us

EPDM Rubber Waterproof Membrane for Ponds with 1.0mm/1.2mm/1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords