EPDM Coiled Rubber Waterproof Membrane with Recycled Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Coiled Rubber Waterproof Membrane with Recycled Material

Description Of EPDM Coiled Rubber Waterproof Membrane with Recycled Material:

•EPDM waterproof sheet has excellent anti-ozone-aging performance, able to resist ultraviolet light and corrosion of many chemical corrosive materials in the atmosphere

•It has high tensile strength, high ductility and strong retractility, it has excellent crack resistance, able to effect waterproof function even with tiny vibration of buildings.

• Excellent resistance to ozone, oxidation and sunlight.

• Resistance to chemicals; resistant to most inorganic products.

Main Features of EPDM Coiled Rubber Waterproof Membrane with Recycled Material:

A.Polyester based SBS Modified Bitumen Waterproofing Membrane

a. Strong impermeability

b. High tensile strength, elongation, ability to adapt the grassroots shrinkage deformation and cracking

c. Puncture-resistant, broken resistant, tear-resistant

d. The corrosion resistance, resistance to mildew, weathering good

e. Construction convenient, hot-melt can be operated Four Seasons Construction, reliable joints

Specifications of EPDM Coiled Rubber Waterproof Membrane with Recycled Material:

| Material | EPDM Rubber |

| Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

| Thick | 1.2mm, 1.5mm, 2.0mm |

| Type | Vulcanized & Weldable |

| Pattern | Non-reinforced (homogeneous) |

| Certificate | ISO9001/14001 |

Applications of EPDM Coiled Rubber Waterproof Membrane with Recycled Material:

1. The substratum should be smooth, dry, clean, which can not have loosing and peeling phenomena.

2. Before application, clean up the basic level and eradicate the impurities.

3. Spread out the membrane on the substratum to loose sheet's stress. Use adhesive-glue to paint the substratum and the surface of membrane. When the adhesive is not sticky to hands, pave and press smoothly.

4. When pave the second volume of membrane, extrude 100mm of the edge of overlap of the first roll and do not paint with the adhesive. Pave the membrane on the substratum according to step so as to finish the whole pavement. When paving, do not tighten the waterproof membrane violently.

5. After that, use the special solvent to scrub the overlap joint. When it becomes fully dry , use the sheet glue to paint the both sides of the joint. Paint it again when it gets completely dry. Till the adhesive is not sticky to hands, press it smoothly and solidly.

6. Pay attention to fire prevention during application. Basement construction site shall be equipped with ventilation facilities

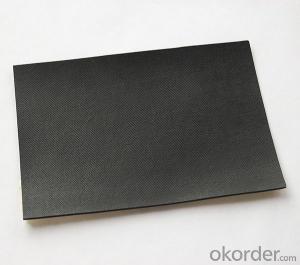

IMages of EPDM Coiled Rubber Waterproof Membrane with Recycled Material:

FAQ of EPDM Coiled Rubber Waterproof Membrane with Recycled Material:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Does a waterproofing membrane require any special tools or equipment for installation?

- Yes, the installation of a waterproofing membrane typically requires some special tools and equipment. These tools and equipment are necessary to ensure a proper and effective installation. Some common tools used during the installation process include a trowel, roller, brush, and squeegee. These tools help in applying the membrane evenly and smoothly. Additionally, specialized equipment such as a heat gun or torch may be required for certain types of waterproofing membranes that require heat activation. It is important to follow the manufacturer's instructions and guidelines when it comes to the tools and equipment needed for the specific type of waterproofing membrane being used. Using the correct tools and equipment will help ensure a successful installation and enhance the performance and longevity of the waterproofing membrane.

- Q: Can a waterproofing membrane be used on metal surfaces?

- Yes, a waterproofing membrane can be used on metal surfaces. Waterproofing membranes are versatile and can adhere to various materials, including metal. They provide effective protection against water damage and can be applied to roofs, walls, and other metal surfaces to prevent leaks and corrosion.

- Q: Can a waterproofing membrane be used for a parking garage deck protection?

- Yes, a waterproofing membrane can be used for parking garage deck protection. A waterproofing membrane is specifically designed to prevent water infiltration and protect the underlying structure from moisture damage. In the case of a parking garage deck, where constant exposure to water, vehicular traffic, and potential chemical spills can occur, a waterproofing membrane can provide an effective barrier against these elements. By applying a waterproofing membrane to the parking garage deck, you can prevent water from seeping through the concrete and reaching the underlying steel reinforcement. This helps to avoid corrosion and deterioration of the structure, extending its lifespan and reducing the need for costly repairs or replacements. Furthermore, a waterproofing membrane can also protect the deck from other potential sources of damage, such as oil or chemical spills from vehicles. It creates a barrier that prevents these substances from penetrating the concrete and causing stains or deterioration. Additionally, a waterproofing membrane can enhance the overall durability and strength of the parking garage deck. It can help to minimize cracking, spalling, and other forms of concrete damage that can occur due to freeze-thaw cycles, temperature fluctuations, or heavy loads. Overall, using a waterproofing membrane for parking garage deck protection is a highly recommended solution to ensure the longevity and structural integrity of the parking facility. It provides a reliable defense against water infiltration, chemical spills, and other potential sources of damage, ultimately reducing maintenance costs and extending the lifespan of the parking garage deck.

- Q: Can a waterproofing membrane be used for disaster relief structures?

- Yes, a waterproofing membrane can be used for disaster relief structures. Waterproofing membranes are designed to prevent water penetration and can be an effective solution for protecting temporary structures in disaster-affected areas. Whether it is a temporary shelter, medical facility, or storage unit, a waterproofing membrane can provide a barrier against rain, floods, and other water-related challenges. By ensuring that the structure remains dry, it helps maintain the integrity of the relief structure and protects the occupants or stored supplies from water damage. Additionally, waterproofing membranes are often lightweight, easy to install, and can be quickly deployed in emergency situations, making them ideal for disaster relief efforts.

- Q: Can a waterproofing membrane be used for a parking lot?

- Yes, a waterproofing membrane can be used for a parking lot. A waterproofing membrane is designed to provide a protective barrier against water infiltration and can be applied to various surfaces, including parking lots. It helps to prevent water damage, such as cracks and deterioration caused by freeze-thaw cycles, and can extend the lifespan of the parking lot. Additionally, a waterproofing membrane can also help to mitigate the risk of costly repairs by preventing water from seeping into the subbase and compromising its stability. Overall, using a waterproofing membrane for a parking lot can be a smart investment to enhance durability and longevity while minimizing maintenance needs.

- Q: Are waterproofing membranes resistant to diesel fuel?

- Typically, diesel fuel is not resisted by waterproofing membranes. Being a petroleum-based substance, diesel fuel can harm various types of waterproofing materials. The membrane's integrity can be degraded, reducing its ability to prevent water from penetrating. Consequently, it is crucial to avoid exposing waterproofing membranes to diesel fuel since it can compromise their effectiveness and durability. If there is a chance of diesel fuel coming into contact with the membrane, it is advisable to employ extra protective measures like chemical-resistant barriers or a secondary containment system to avert any potential harm to the waterproofing membrane.

- Q: Can a waterproofing membrane be applied on both interior and exterior surfaces of a structure?

- Yes, a waterproofing membrane can be applied on both interior and exterior surfaces of a structure.

- Q: Can a waterproofing membrane be used in conjunction with green building practices?

- Certainly, a waterproofing membrane can be utilized alongside green building practices. In actuality, integrating a waterproofing membrane into the construction of a green building can greatly enhance its overall sustainability and efficiency. One of the fundamental principles of green building practices is to maximize energy efficiency and decrease the environmental impact of a structure. By installing a waterproofing membrane, the building's outer covering can be shielded from moisture intrusion, thereby preventing water damage and potential mold growth. This, in turn, aids in preserving the structural integrity of the building, reducing the necessity for costly repairs and replacements, which can consume resources and generate waste. Moreover, a waterproofing membrane can contribute to improved indoor air quality. By preventing water infiltration, it assists in creating a dry and healthy living or working environment, minimizing the risk of respiratory problems and other health issues associated with dampness. Furthermore, a waterproofing membrane can enhance the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it lessens the potential for heat loss through moisture evaporation, thus reducing the energy required for heating and cooling. This can lead to decreased energy consumption and lower carbon emissions, aligning with the objectives of green building practices. However, it is crucial to select a waterproofing membrane that is environmentally friendly and compliant with green building standards. Seek out membranes that are crafted from recycled or sustainable materials and possess low VOC (volatile organic compound) content. Additionally, consider opting for a membrane that is designed for longevity and durability, as this can further minimize the environmental impact by reducing the need for replacement over time. In conclusion, a waterproofing membrane can be an invaluable addition to any green building endeavor. It serves to safeguard the building envelope, enhance indoor air quality, and improve energy efficiency. By choosing an environmentally friendly membrane, the overall sustainability of the building can be further enhanced.

- Q: Is a waterproofing membrane resistant to UV radiation?

- Yes, a waterproofing membrane is typically resistant to UV radiation. Most waterproofing membranes are designed to be durable and long-lasting, and part of that includes being able to withstand exposure to UV rays. UV radiation from the sun can cause degradation and damage to various materials over time, including waterproofing membranes. However, manufacturers often incorporate UV stabilizers and additives into the membrane's composition to enhance its resistance to UV radiation. These additives help to prevent the breakdown of the membrane's structure, ensuring that it remains effective in preventing water infiltration and maintaining its overall performance for an extended period, even when exposed to direct sunlight. Additionally, some waterproofing membranes may have a protective layer or coating that offers additional UV resistance. It is always recommended to consult the manufacturer's specifications and guidelines to understand the specific UV resistance capabilities of a particular waterproofing membrane.

- Q: Does a waterproofing membrane require any curing time before it can be exposed to water?

- Before being exposed to water, a waterproofing membrane does require a curing time. This curing time is necessary for the membrane to fully bond and reach its maximum strength, durability, and waterproofing capabilities. The specific duration of the curing time may vary depending on the type of membrane and the instructions provided by the manufacturer. To ensure proper curing and effective protection against water intrusion, it is crucial to adhere to these instructions. Neglecting to allow sufficient curing time can compromise the membrane's effectiveness, potentially resulting in leaks or other related issues. Therefore, it is highly recommended to wait until the specified curing time has passed before exposing the waterproofing membrane to water.

Send your message to us

EPDM Coiled Rubber Waterproof Membrane with Recycled Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords