EPDM Pond Linder Waterproof Membrane for Garden System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

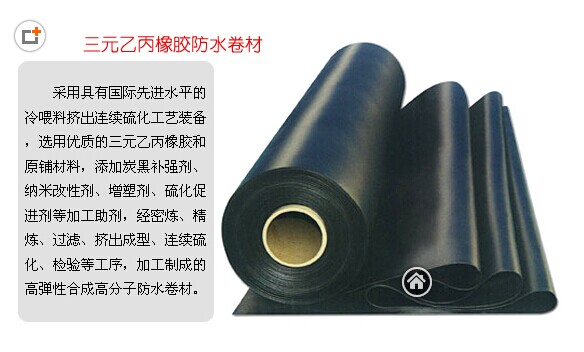

EPDM waterproofing Rubber membrane

1. Introduction of EPDM Waterproofing Membrane:

This waterproof coiled material is of high elasticity with best performance among high polymer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber of ‘CHEN SHENG’ brand is produced with the use of the most advanced continuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,performances reach or exceed the demands of GB18173.1-2012 standard.

2. Detail Specification of EPDM Waterproofing Membrane:

Type | EPDM Waterproof Membrane | ||

Material | EPDM Rubber | ||

Thickness | 1.2mm | 1.5mm | 2.0mm |

Weight(kg/m2) | 1.54-1.58 | 1.79-1.83 | 2.25-2.29 |

Size | 1.2m(width) * 20m(length)/roll | ||

Type | Vulcanized & Weldable | ||

Pattern | Non-reinforced(homogeneous) | ||

Packing | 24sqm/roll, with plastic bag | ||

Color | Black | ||

Application | Roof, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | ||

3. Features of EPDM Waterproofing Membrane:

1>Excellent anti-aging performance, service life up to 50 years

2>Working well with in -40-100 degree, it can be constructed with a single layer in ambient temperature.

3>Waterproofing on various kinds of underground project,industrial of civil buildings and structures. 4>high extension rate, high tensile strength, small size changes at heat treatment

5>Good plant roots penetrability resistance and can be made waterproofing layer of planting roof 6>Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem . 7>Good low temperature flexibility, and good performance of adapting to ambient temperature changes. 8>Convenient application ,solid joint, no environment pollution

9>chemical corrosion Resistance, can be used for special occasions

4. Technical Data of EPDM Waterproofing Membrane:

ITEM | STANDARO REQUEST | |

Tensile strength at breaking,normal temperature,Mpa | ≥7.5 | |

Elongation at breaking, % | ≥450 | |

Tearing strength,KN/m | ≥25 | |

Bending at low temperature | ≤-40°C | |

Water impermeability,0.1Mpa×30min | Impermeability | |

Hot air aging 80°C×168h | Unchanging of tensile strength at breaking,% | ≥80 |

Unchanging of elongation at breaking,% | ≥70 | |

Appearance of 100% elongation | No crack | |

Property of anti alkali 10% Ca(OH)2×168h normal temperature | ≥80 | |

≥80 | ||

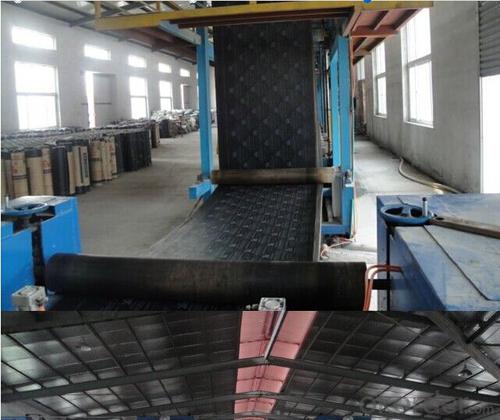

4. Some photos:

- Q: It is good for black roof with waterproof paper

- No film or PE film (black surface) coil is generally not used for the roof; if the roof is often on the need to lay in the coil above the 5 cm thick cement mortar to do the protective layer or the choice of sand and shale surface waterproof Coil. Lough membrane (silver surface) The role of the membrane to play the radiation can be used directly for the roof without any protection.

- Q: Are waterproofing membranes suitable for tunnels?

- Yes, waterproofing membranes are suitable for tunnels. They provide an effective barrier against water infiltration and can help prevent water damage and deterioration of the tunnel structure.

- Q: Does a waterproofing membrane add any additional insulation to a structure?

- No, a waterproofing membrane does not add any additional insulation to a structure. Its primary function is to prevent water penetration and protect the building from moisture damage. Insulation is a separate component that is designed to control heat transfer and improve energy efficiency in a structure.

- Q: Can a waterproofing membrane be covered or concealed by other finishes or materials?

- Yes, a waterproofing membrane can be covered or concealed by other finishes or materials. This is commonly done in construction projects to create a visually appealing and functional surface while still ensuring the waterproofing integrity of the structure.

- Q: Can a waterproofing membrane be used in areas with high foot traffic or heavy loads?

- Yes, a waterproofing membrane can be used in areas with high foot traffic or heavy loads. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can withstand various types of stress, including foot traffic and heavy loads. However, it is important to choose a waterproofing membrane that is specifically designed for these conditions. There are different types of membranes available, each with varying levels of durability and strength. It is crucial to consult with a professional waterproofing expert or manufacturer to ensure that the chosen membrane is suitable for the specific requirements of the area with high foot traffic or heavy loads. Proper installation and maintenance of the membrane are also essential for its long-term effectiveness in these conditions.

- Q: Can a waterproofing membrane be used for underground parking garages?

- Underground parking garages greatly benefit from the utilization of a waterproofing membrane. To safeguard against water infiltration and consequent harm, it is highly advised to employ such a membrane in these specific structures. Surrounding soil often poses a threat of water seepage in underground parking garages, leading to structural decline, corrosion of steel reinforcements, and the proliferation of mold and mildew due to constant exposure to moisture. A waterproofing membrane acts as a protective barrier, effectively preventing water from permeating the walls and floors of the garage. It is carefully applied to the exterior surfaces of the structure, forming a shield that ensures the interior remains dry and devoid of water-related issues. The selection of the appropriate membrane should be based on project-specific requirements, taking into account factors such as construction materials, groundwater conditions, and expected water pressure levels. Furthermore, proper installation techniques and regular maintenance are paramount to ensure the long-term efficacy of the waterproofing system.

- Q: Can a waterproofing membrane be used in residential construction?

- Residential construction can indeed utilize a waterproofing membrane. These membranes find common usage in different parts of a residential property, such as roofs, basements, bathrooms, and foundations. Their purpose is to prevent water from penetrating and causing damage due to moisture. By opting for a waterproofing membrane, homeowners can ensure that their property remains dry and free from water leaks. This is crucial because such leaks can result in mold growth, structural deterioration, and other costly problems. The market offers a variety of waterproofing membranes, such as sheet membranes, liquid membranes, and self-adhering membranes, each with its own advantages and suitability for specific applications. Consulting with a professional contractor or architect can assist in determining the most suitable waterproofing membrane for a particular residential construction project.

- Q: Can a waterproofing membrane be used on tunnels with emergency exits?

- Yes, a waterproofing membrane can be used on tunnels with emergency exits. In fact, it is highly recommended to use a waterproofing membrane in such tunnels to prevent water infiltration and protect the structural integrity of the exits. Waterproofing membranes are designed to create a barrier against water and moisture, ensuring that the tunnels remain dry and free from water damage. This is especially important for emergency exits, as they need to be accessible and functional at all times. By installing a waterproofing membrane, the tunnels can be effectively protected from potential water ingress, ensuring the safety and usability of the emergency exits.

- Q: Does a waterproofing membrane require a primer before application?

- Yes, a waterproofing membrane usually requires a primer before application. The primer helps to improve adhesion between the membrane and the substrate, ensuring a strong and durable bond. It also helps to seal the surface, preventing any moisture or contaminants from interfering with the membrane's performance. Applying a primer before the membrane ensures better effectiveness and longevity of the waterproofing system.

- Q: Can a waterproofing membrane be used on aluminum surfaces?

- Indeed, aluminum surfaces can benefit from the application of a waterproofing membrane. Such membranes possess great versatility, enabling their use on a wide range of surfaces, including aluminum. Their purpose is to create a safeguarding barrier against water and moisture, effectively preventing any potential leaks or water-related harm. By employing a waterproofing membrane on aluminum surfaces, the material's longevity can be significantly extended as it remains protected from the detrimental effects of corrosion and rust, which are often triggered by water exposure. Nevertheless, it is imperative to carefully select a waterproofing membrane that is both compatible with aluminum and suitable for the specific application in order to achieve the most optimal outcomes.

Send your message to us

EPDM Pond Linder Waterproof Membrane for Garden System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords