EPDM Rubber Waterproof Membrane for Gardens

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

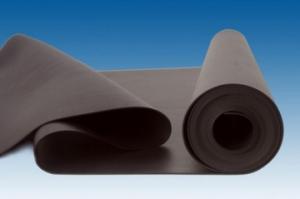

EPDM Rubber Waterproof Membrane for Gardens

Description Of EPDM Rubber Waterproof Membrane for Gardens:

This waterproof coiled material is of high elasticity with best performance among high polumer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber is produced with the use of the most advanced contiuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,perfomances reach or exceed the demands of GB18173.1-2000 standard.

Main Features of EPDM Rubber Waterproof Membrane for Gardens:

1.EPDM waterproof membrane for bridge engineering waterproof

2.EPDM waterproof membrane for water conservancy projects ,such as river bank,lake dam seepage.

3.EPDM waterproof membrane for the municipal engineering.

4.EPDM waterproof membrane for aquaculture.

Specifications of EPDM Rubber Waterproof Membrane for Gardens:

| Number | Item | Unit | Value | |

| 1 | Size Variation | Thichness | % | ±10 |

| Width | % | ±1 | ||

| Length | % | Allowed negative | ||

| 2 | Breaking tensile strength at normal temperature | Mpa | ≥7.5 | |

| Breaking tensile strength at 70°C | Mpa | ≥2.3 | ||

| 3 | Breaking elongation at normal temperature | % | ≥450 | |

| Breaking elongation at -20°C | % | ≥200 | ||

| 4 | Tear strength | KN/m | ≥25 | |

| 5 | Impermeability(30min) | * | 0.3Mpa no leakage | |

| 6 | Bending at low tempreture | °C | ≤-40 | |

| 7 | Stretch tensor at heating | Elongate | mm | ≤2 |

| Shrink | mm | ≤4 | ||

| 8 | Air oven aging(80°C×168h) | Tensile strength at break retained | % | ≥80 |

| Elongation at break retained | % | ≥70 | ||

| 9 | Anti-alkali | Tensile strength at break retained | % | ≥80 |

| Elongation at break retained | % | ≥80 | ||

| 10 | Nuture weathing at manual simulation | Tensile strength at break retained | % | ≥80 |

| Elongation at break retained | % | ≥70 | ||

Applications of EPDM Rubber Waterproof Membrane for Gardens:

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation.

IMages of EPDM Rubber Waterproof Membrane for Gardens:

FAQ of EPDM Rubber Waterproof Membrane for Gardens:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be repaired if damaged?

- Yes, a waterproofing membrane can be repaired if it is damaged. The extent and type of damage will determine the appropriate repair method, which could involve patching or sealing the damaged area.

- Q: Can waterproofing membranes be used on concrete pools?

- Yes, waterproofing membranes can be used on concrete pools. These membranes are designed to prevent water from penetrating the concrete and causing damage. They create a barrier that keeps the water inside the pool, ensuring its structural integrity and preventing any leaks or seepage.

- Q: Can a waterproofing membrane be used in areas with high foot traffic or heavy loads?

- Yes, a waterproofing membrane can be used in areas with high foot traffic or heavy loads. Waterproofing membranes are designed to provide durability and protect the underlying structures from water damage. They are often used in areas such as basements, balconies, and rooftops, which may experience heavy foot traffic or support heavy loads. However, it is important to choose a membrane specifically designed for high traffic or heavy load areas to ensure it can withstand the intended use.

- Q: Does a waterproofing membrane require any special tools for installation?

- Yes, installing a waterproofing membrane typically requires special tools such as a trowel, brush or roller for application, utility knife for cutting the membrane, and a heat gun for seam sealing.

- Q: Can a waterproofing membrane be used on concrete tanks?

- Concrete tanks can indeed benefit from the use of a waterproofing membrane. The primary purpose of this membrane is to create a barrier that prevents water from penetrating through. It is specifically designed to be applied on various surfaces, including concrete. Waterproofing membranes are especially useful for concrete tanks that are used for water storage or containment. By applying the membrane on the concrete surface, a protective layer is formed that effectively stops water from entering or exiting the tank. This is crucial for maintaining the tank's structural integrity and avoiding any potential damage or contamination caused by water leakage. Furthermore, these membranes also offer protection against other substances that may be present in the tank, such as chemicals or pollutants. It is important to choose the right type of membrane that suits the specific requirements of the concrete tank. Following the manufacturer's instructions for application is also essential to ensure that the waterproofing is effective and long-lasting.

- Q: Can a waterproofing membrane be used on asphalt surfaces?

- Yes, a waterproofing membrane can be used on asphalt surfaces. Waterproofing membranes are commonly used in construction and are designed to provide a protective barrier against water infiltration. They are versatile and can be applied to various surfaces, including asphalt. Applying a waterproofing membrane on an asphalt surface can help prevent water damage, increase the longevity of the surface, and protect the underlying structures. It is important to ensure that the waterproofing membrane used is compatible with asphalt and that proper installation techniques are followed to achieve optimal results.

- Q: Can a waterproofing membrane be used in new construction?

- A waterproofing membrane is capable of being utilized in new construction. In fact, it is frequently advised to incorporate a waterproofing membrane during the construction phase to furnish an extra layer of safeguard against water harm. Typically, waterproofing membranes are administered to the external foundation walls and basement floors to obstruct water infiltration and construct a barrier against moisture. This can effectively avert predicaments like leaks, mold, and structural damage in the long run. Furthermore, waterproofing membranes can also be employed in other areas of a new construction project, such as roofs, balconies, and bathrooms, to guarantee long-lasting waterproofing protection. On the whole, the utilization of a waterproofing membrane in new construction can contribute to the extension of the building's lifespan and instill peace of mind for its occupants.

- Q: Can a waterproofing membrane be installed by a homeowner or is professional installation required?

- Although a homeowner can technically install a waterproofing membrane, it is strongly advised to enlist the services of a professional. Several factors must be taken into consideration, making professional installation the superior choice. To begin with, proper installation of waterproofing membranes necessitates specific knowledge and expertise. Professionals are trained in the correct techniques and possess experience working with various membrane types. They understand the intricacies of the process, including surface preparation, membrane application, and sealing. This expertise guarantees correct installation and effective waterproofing. Furthermore, professionals have access to top-quality materials and tools that homeowners may not readily have access to. They possess knowledge of which membrane type is appropriate for various applications and can recommend the best product based on individual needs. Additionally, professionals have access to specialized equipment, enabling more efficient and effective installation. In addition, professional installation offers the advantage of warranties and guarantees. Reputable waterproofing companies typically provide warranties for their services, providing homeowners with peace of mind. They can trust that any issues that arise will be addressed and resolved by the professionals. Lastly, waterproofing is essential for safeguarding homes against water damage and maintaining structural integrity. Improper installation or a faulty membrane can lead to water leaks, mold growth, and expensive repairs. By hiring a professional, homeowners can be confident that the waterproofing membrane will be installed correctly, reducing the risk of future problems. In conclusion, while it is possible for homeowners to install waterproofing membranes themselves, the complexities of the process and the advantages of professional installation make it highly recommended to hire a professional for this task. Their expertise, access to quality materials, warranties, and guarantees provide homeowners with the reassurance that the job will be carried out correctly and effectively, ultimately protecting their homes from water damage.

- Q: Why is the top cover of the basement waterproofing? While the floor has to empty shop?

- Basement waterproof construction specification. Basement waterproofing acceptance specification.

- Q: Can a waterproofing membrane be used for elevator pits?

- Yes, a waterproofing membrane can be used for elevator pits. Elevator pits are typically located at the lowest level of a building and are prone to water infiltration, especially in areas with high groundwater levels or heavy rain. Installing a waterproofing membrane in the elevator pit can help prevent water from seeping in and causing damage to the elevator machinery or compromising the structural integrity of the pit. Waterproofing membranes are designed to create a barrier against water penetration and can be applied to the walls and floor of the elevator pit to ensure maximum protection. It is important to choose a high-quality waterproofing membrane that is specifically designed for below-grade applications and is capable of withstanding the constant exposure to moisture. Additionally, proper installation by trained professionals is crucial to ensure the effectiveness and durability of the waterproofing system.

Send your message to us

EPDM Rubber Waterproof Membrane for Gardens

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords