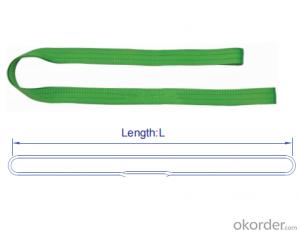

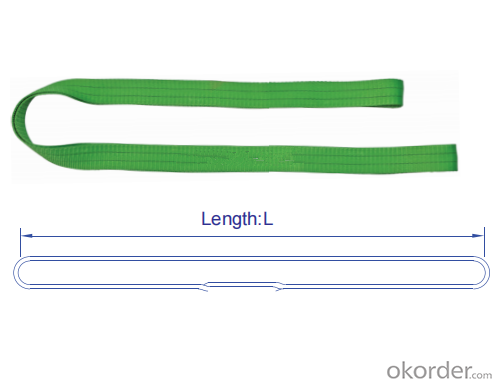

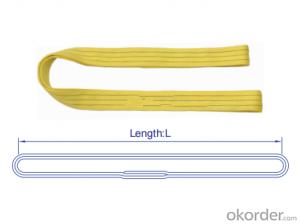

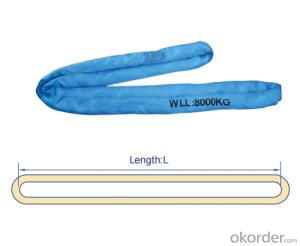

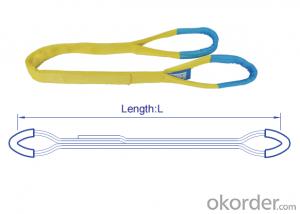

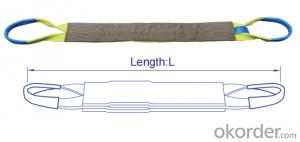

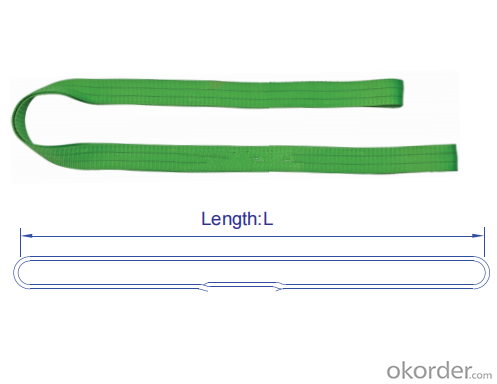

Endless Type 2m Textile Sling With 12t Webbing Sling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

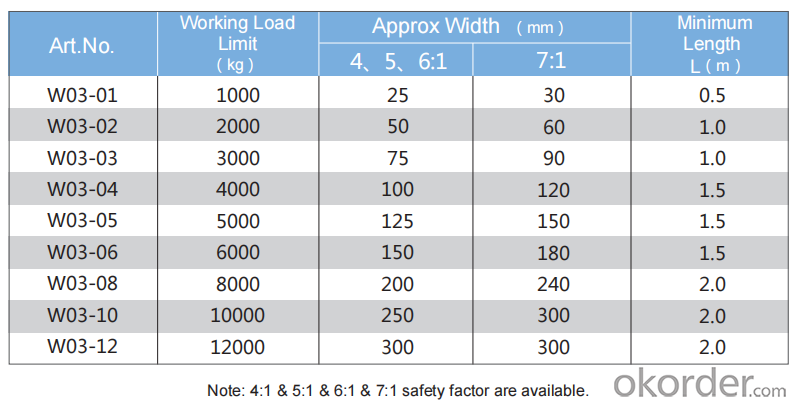

Specification

Endless Type 2m Textile Sling With 12t Webbing Sling

Chracteristics:

Soft, light, no harm to the cargo, safety, long life and so on.

Light and soft, can be used in small narrow space.In PU processing, anti-abrasion is enhanced,Non-conductive, no danger of electric stroke.

Product usage :

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

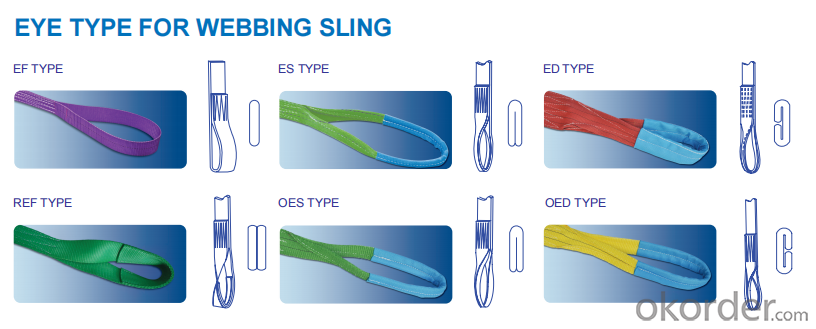

More Type:

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:1.210 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

- Q: What is the difference between cable stayed bridge and suspension bridge?

- Cable stayed bridge is one of the most popular types of long-span bridges in china. So far, there are more than 3O cable-stayed bridges completed or under construction, second only to Germany and Japan, and the third place in the world. And the number of long-span concrete cable-stayed bridges has been ranked first in the world.In the middle of 50s, the first modern cable-stayed bridge was built in Sweden. For more than 40 years, the development of cable-stayed bridge has a strong momentum. In the middle of 70s, China began to build concrete cable-stayed bridges. After the reform and opening up, the momentum of the construction of cable-stayed bridges in China has been on the rise.China has been developing the concrete cable-stayed bridge mainly. In recent years, China has begun to build a hybrid cable-stayed bridge with steel and concrete, such as the Shantou stone bridge, the main span 518m, and the Yangtze River Third Bridge in Wuhan, the main span 618m. Steel box cable-stayed bridges, such as Nanjing Changjiang second bridge, South Branch bridge, main span 628m, Wuhan military mountain Yangtze River bridge, main span 460m. A few years ago, the Nanpu (main span 423m) and Yangpu (main span 6O2m) bridge built in Shanghai were steel and concrete composite beam cable-stayed bridges.

- Q: What are the connections and differences between hooks, slings, rings and heavy truck rings in cranes? What are the hoisting designs?

- Synthetic fiber tape series: flexible sling, sling, ring ring cylinder cylinder eye sling, sling, flat glass, polypropylene flat sling, sling, sling fastening belt, pickling container windproof belt, hand woven tape, tied with tape, nylon, special oil pipeline pipe sling, sling dupont. (flat suspenders can produce 1T-30T, flexible suspenders, which can produce 1T-300T)

- Q: What is the line on the train for?

- It's called catenary. There are two lines up and down. The upper part is called the load line, and the lower one is called the contact line. There is a sling connection between the cord and the contact wire.

- Q: Requirements and matters needing attention in hoisting

- Hoisting tower tank by using rotary method or down method, wrist hinge at the bottom of the tower installation must have the ability level of the thrust generated resistance during lifting, the lifting process of the tower body around the ropes must be reliable, the tower height of the rotary position, slowly falling into the foundation, avoid accidents and deformation.

- Q: They are used for slings, ropes, chains, suspenders, hand hoists, right?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility of. According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q: What's the catch?

- Slings are ropes made of wire or synthetic fiber, used for hoisting.

- Q: What torture refers to the lever and the sling

- The sling hanging and torture half pig "(only one side of the body hanging victims), pawn (tied hanging arm and feet) and so on, all belong to the suspension of torture throughout human skin nerve endings, the feeling is very sensitive, in the daily life of people on the outside of the pain, is the nerve end suspension shoot at work. Some nerve endings, such as fingers, toes, sexual organs, etc., are more acute and abnormal. The distribution of the human nerve network also forms many subcutaneous sensitive areas, such as the two sides of the spine, the armpit, the medial thigh, the two rib, and so on. Therefore, the users of torture also torture people according to these physiological characteristics of the human body, and bring great suffering to the sufferers with more labor-saving means. The vast majority of the torture we know fall into this category, and the torture against women is basically the same.

- Q: What are the specifications for the length, length, and method of operation of the wire rope?

- The fatigue life is three times the same structure of plain steel wire rope, the highest value of contrast test has reached an alarming four times, can be verified by fatigue test, fatigue life ability if they have on their own to do comparative experiments, this test results the most credible, the service life of wire rope and the fatigue life is proportional to a long fatigue life use the same proportion of life extension, the use of lower cost, better stability.

- Q: Slings and rigging manufacturers, which cost-effective?

- Phosphating coating of steel wire rope than plain steel wire rope has long service life, lower cost, better stability, phosphating coating of steel wire rope is patent technology production, because the demand is more difficult to buy, to ask the producer of several wire rope, please note in the purchase, purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope to prevent illegal enterprises, infringement of their legitimate rights and interests, in addition, patent products are generally in the rope on the outer packing of a patent spraying label, warranty should be the main technical indicators, such as the phosphating film type and film weight

- Q: How to choose the right sling?

- According to the current market situation of wire rope, manganese phosphating coating of steel wire rope price is higher than that of plain steel wire rope, and prolonging the service life of much higher than the rate of price increase, so the phosphating coating steel wire rope daily use fee is only about 30% of the plain steel wire rope, the average daily use of lower cost, higher quality and price stability is. Replacement of wire rope smooth upgrade.Lifting equipment commonly used wire rope varieties of phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating. For reference only.

Send your message to us

Endless Type 2m Textile Sling With 12t Webbing Sling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches