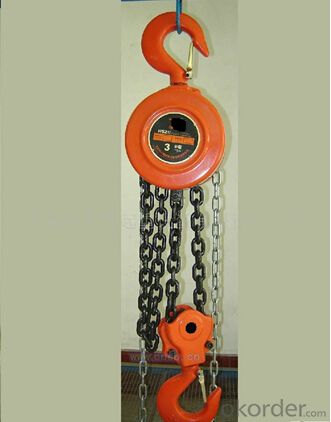

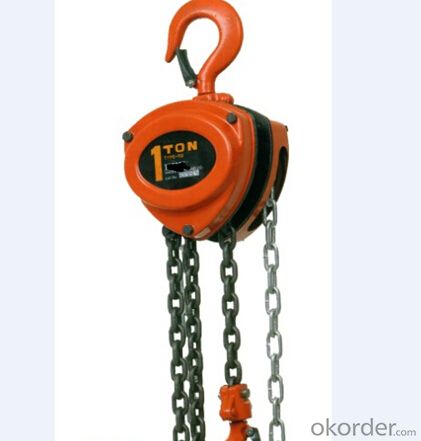

CNBM Hoisting CE 1ton Chain Hoist high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Place of Origin: Hebei, China (Mainland)

Brand Name: CNBMModel Number: HS-Z Type Chain Hoist

Usage: Construction Hoist

Power Source: Hand Chain

Sling Type: Chain

Maximum Lifting Weight: 3000kg

Maximum Lifting Height: 3m or as request

Lift Speed: Manual by youself

Certification: CE,GS,ISO

Warranty: 1year

After-sales Service Provided: Engineers available to service machinery overseas

Safety Factor: 4:1

Running Test Load: 4500kg

Chain material: G80 steel chain

Hook material: Forged steel

OEM/ODM: Available

Chain block Color: red or as request

No. of falls of load chain: 2

Available capacity: 0.25ton-30ton

Main Features

Superior rigidity makes the hoist dust-proof and water-pfoof;

Severe environment and work condition are acceptable;

Simple structure and few components

Adopt Janpanese FEC chain;

To greatly enhance the performance of the fatigue and wearresistance.

Limit protection adevice can avoid overload occerring;

Hook bolt can prevent the rigging accidently from slip;

Moter is equipped with thermal protection device;

limit contactors are set in the machine.

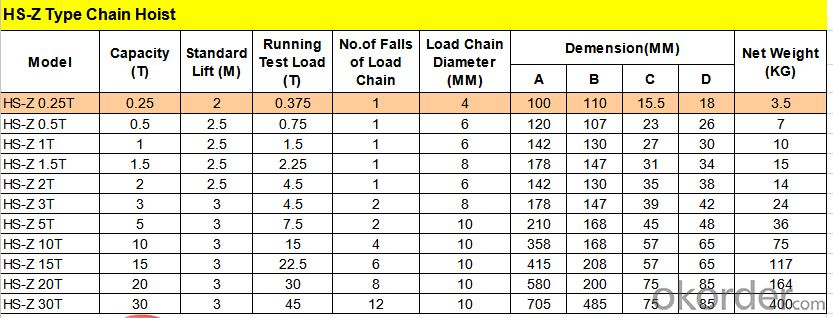

Parameter List

FAQ

Thank you for visiting our Huaige Hoist Machinery Manufacturing Co. Ltd website. We hope you’ve found a few things of value that will benefit you on the business.

For more information on doing business with us, please check the Frequently Asked Questions(FAQ) as followed:

1. Do you accept Small order?

Only a trial sample order with small quantity is acceptable. Since we are a manufacturer and wholesaler, good quality at competitive price will help you save more cost. And quantity discount is provided.

2. How to order?

Please send us your purchase order by Email or Fax, or you can ask us to send you Performa Invoice for your order. We need to know the following information for your order:

1) Product information:

Quantity, Specification including capacity, lifting height, power supply (such as 380V, 3phase, 50Hz), size, material, color and packing and Special requirements.

2) Delivery time: Please advise when you need the goods, if you need urgent order, do tell us in advance, then we can arrangle it well.

3) Shipping information: Company name, Address, Phone number, Destination seaport/airport.

4) Forwarder's contact details :if you have in China.

3. What is the sample policy?

We would like the send you sample for quality checking and testing. And buyer should pay for the sample cost and freight charges. And sample cost can be deducted from official orders accordingly, this is special for long terms business partners.

4. What is your payment term?

We accept T/T, Western Union in US dollars.

5. How will my order be shipped?

Usually shipped by sea, small or urgent order can be sent by Air or Express (DHL, TNT, UPS or FedEx) after approval.

6. Are you a factory? Where is it?

Yes, we are a professional manufacturer on this line for lifting equipment since 1999. Our factory is located in CNBM Industrial Park, Baoding City, Hebei Province, China. Welcome to visit our factory at any time!

7. What products can you supply?

We are specialized in chain block, lever block, electric hoist, electric winch, truss chain hoist for stage, manger lifter, cargo trolley, fork lifter, floor crane. Webbing slings, cargo lashing, hydraulic jack. And hoist accessories including load chain, wire rope, rigging, hook, pulley ans shackles etc.

- Q: What tools are slings in lifting operations? What is the function of the slings?

- A sling is also called a jack rope, a pair of rope or rope buckle. Hoisting works are more used, such as tying equipment, hanging blocks, stabilizing winches and so on. The utility model has the advantages of good quality and large elasticity, but the rigidity is large, and the bending is not easy, and once the bend is not easy to recover. Slings made of wire ropes of hemp core are not easy to work under high temperature.

- Q: Where should I pay attention to the formwork?

- (1) Kennedy to support part of the template and scaffold, when installed in the soil on the plate should be added, and the foundation must be solid and drainage measures of collapsible loess, there must be waterproof measures; frost heaving of soil is stopped, there must be anti freeze thaw measures.(2) in the course of installation of the formwork and its support, the temporary fixing equipment should be set up.

- Q: Do cranes have the same wire ropes, slings, slings and cables?

- My understanding is different. The cable refers to the cables used for power supply or the cables used for hanging lamps.

- Q: How much is the crane arm of the tower from the residential building recently?

- No aluminum conductor or steel shall be used as grounding or ground wire for the installation of tower cranes. A bolted wire must have an end. Grounding is mainly made up of the following three ways:1. the grounding body adopts a regular grounding pile, or a 33*4.5 long 1.5m steel tube, or a 70*70 long 1.5m angle steel.2. the floor is made of steel plates or other metal plates with an area of 1 square meters. The ground is deep from the ground 1.5m.3. a copper conductor with a cross-section of not less than 28 mm or a steel conductor with a cross section of not less than 50 mm is buried in the slot and its embedment length is determined by the grounding resistance.In the above three ways, the grounding body leads the copper conductor, the sectional area shall be no less than 25, if the soil is not conductive, the sodium chloride (salt) can be embedded in the soil. Then irrigation. For walking crane, each rail must be grounded, and the two tracks are connected by wires. Electrical connections should also be made between the two rails, with a resistance of no more than 4.

- Q: Which brand is better for imported rigging?

- CarlStahl set up Chinese branch in Hangzhou in 2006, mainly engaged in CarlStahl brand heavy duty crane, lifting fixture, spring balancer, hoist, crane beam, lift hook, rope, wire rope, tie, round sling hoisting products etc..

- Q: How do you tie the wire rope?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

- Q: The wire rope lock can hang a lot of things

- Ask the manufacturer of the rope sling. The tension of the sling is eighty-five percent of the wire rope, then divided by the safety factor 6. The pulling force of the wire rope is related to the wire rope structure, diameter and intensity level. It is for reference only.

- Q: Slings and rigging manufacturers, which cost-effective?

- Phosphating coating of steel wire rope than plain steel wire rope has long service life, lower cost, better stability, phosphating coating of steel wire rope is patent technology production, because the demand is more difficult to buy, to ask the producer of several wire rope, please note in the purchase, purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope to prevent illegal enterprises, infringement of their legitimate rights and interests, in addition, patent products are generally in the rope on the outer packing of a patent spraying label, warranty should be the main technical indicators, such as the phosphating film type and film weight

- Q: Which sling manufacturer is more reliable?

- Rigging is made of wire rope, plug or aluminium alloy head, and the key to the service life of the rigging is the quality of the wire rope.

- Q: Notice of tower crane?

- The metal structure of the tower crane, the track and the metal shell of all the electrical equipment shall have reliable earthing devices, and the grounding resistance shall not be greater than 4 ohms, and lightning protection devices shall be set up.Fourth. Pole arrangement, each attachment device attached to the wall and spaced distance should be in accordance with the provisions of the original factory, homemade bar design calculations should be.

Send your message to us

CNBM Hoisting CE 1ton Chain Hoist high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords