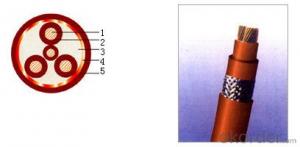

High-Vanadium Cable

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 set

- Supply Capability:

- 0 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

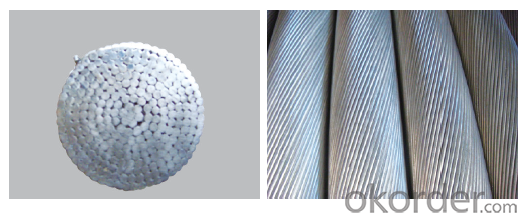

The spiral strands are fabricated by successive spinning of layers generally opposite direction of helix, starting out with a straight core. All the wires are coated with galfan coating which is an alloy combining 95% zinc, 5% aluminum plus specific quantities of rare earth mischmetal. With excellent corrosion resistance and high axial stiffness, the spiral strand cable with galfan coating widely applied to structures like train station, stadium, convention center, membrane structure, glass curtain wall and bridge etc. Our company can produce the spiral strand cable diameter form 20mm to 160mm. The size of 160mm is by far the largest size that made in China. And it has passed the Hebei province scientific and technological achievements appraisal in 2012.

ADVANTAGES

1. Excellent corrosion resistance due to the galfan coating, which is 2-3time of normal galvanizing.

2. Self-compacting and with its metallic texture, it can well matched with the structures.

- Q: What are the connections and differences between hooks, slings, rings and heavy truck rings in cranes? What are the hoisting designs?

- Round nylon lifting rope series: no connecting nylon lifting rope, two button nylon lifting rope, multi nylon lifting rope and shipAnchor rope, rope, paper rope, lifting rope, all kinds of transformer braided rope.

- Q: What's the sling for a movie?

- WIA, is used to protect the athlete's device is generally with a strong rope tied to the athlete's protection belt.

- Q: How do you tie the wire rope?

- The price of phosphating coating wire rope is higher than that of smooth steel wire rope, but the unit use cost is lower than the smooth steel wire rope. The test data indicate that fatigue life of phosphating coating steel wire rope is 3-4 times of plain steel wire rope, wire rope life and fatigue life is proportional to, according to the current market price of roughly wire rope, manganese phosphating coating of steel wire rope although the price is higher than that of plain steel wire rope, and prolonging the service life of much higher than the rate of price increase so, the phosphating coating steel wire rope, the average daily cost of using only smooth steel wire rope 30-45%, longer service life, lower cost per use, stability and security in the process of using and more cost-effective products, light surface wire rope upgrade, for reference only

- Q: What are the installation steps for crane beams?

- Crane operation is relatively dangerous, the installation of crane beam should be standardized to ensure the safety of crane operation. How many points should I pay attention to when installing the crane?:(1) the actual elevation of the corbel should be measured before the installation of the steel crane beam, so that the construction error of the elevation can be adjusted when the crane beam is installed, so as to prevent the error accumulation.The installation sequence of crane beam is as follows: installing crane beam, installing auxiliary truss and installing brake beam.(2) crane shall be used by slings, lashing or reliable clamps. The binding point shall be determined according to the weight and length of the crane beam. Generally, the angle of the sling shall be greater than 45 degrees at the ends of the center of gravity of the crane beam.(3) should be placed after the crane beam, the connecting plate is connected with the fixed edge plate and column crane girder structure, to prevent the crane hook loose after crane girder longitudinal and lateral movement of dumping.(4) crane beam correction should be performed in all bolts after installation, to prevent the installation of bolts when the crane beam shift change; prohibited welding in the crane girder under the flange and web on suspension and fixture.(5) adjust the elevation of the crane beam, correct the center line and span after titanium.

- Q: What are the specifications for the length, length, and method of operation of the wire rope?

- Users need high quality steel wire rope, it should be long life and high quality stable and reliable wire rope.

- Q: Is the sling the same thing as the rigging?

- As for your concept, I have also struggled with it before. I also consulted the professionals who were applying the rigging.

- Q: Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- Finally, the gravity of the main beam becomes the two vertical force of the tower, so that the force passes to the pier under the tower.There are more cables, and the same reason. There are a lot of bars, that's to distract the main girder from the cables.As a kind of cable of cable-stayed bridge, more than beam bridge spanning capacity is the main bridge of long span bridges. The cable stayed bridge is composed of many cables which are directly connected to the tower. The cable-stayed bridge is composed of pylon, main beam and stay cable. The types of pylon are A, inverted Y, H and single column. The materials are steel and concrete. There are single cable plane, parallel double cable plane and inclined cable plane in the stay cable. The first modern cable-stayed bridge was built in Sweden in 1955 and has a span of 182 meters. At present, the largest span cable-stayed bridge built in the world is the Normandy bridge in France, with a main span of 856 meters. The Shanghai Yangpu bridge, built in 1993, is the largest cable-stayed bridge in China, with a main span of 602 meters

- Q: How to choose the right sling?

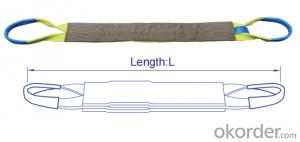

- The selection of rigging should be adapted to the kind of articles, environmental conditions and specific requirements.The sling to carry out strict inspection, in accordance with safety color to use, if found damaged sling can not be reused, need for scrap processing.The slings used for lifting operations must be of the same length.The sling shall not exceed its rated lifting capacity, and the sling shall not exceed its maximum safe working load.

- Q: Which sling manufacturer is more reliable?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

- Q: What are the specifications for the rigging?

- Because the demand is more difficult to buy, to ask the producer of several wire rope, please note in the purchase, purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope, prevent illegal infringement of their legitimate rights and interests of enterprises, in addition, patent products are generally in the rope on the outer packing of a patent spraying mark, warranty due the main technical indicators, such as the phosphating film type and film weight (have an important impact on the weight of phosphating film size, wear resistance and corrosion resistance of the service life of the wire rope, for reference only)

Send your message to us

High-Vanadium Cable

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 set

- Supply Capability:

- 0 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches