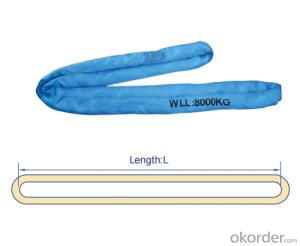

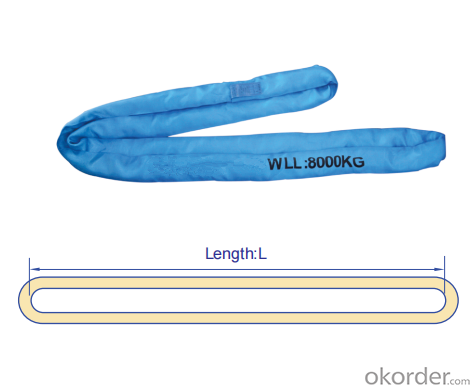

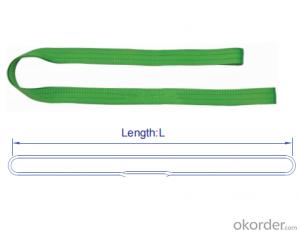

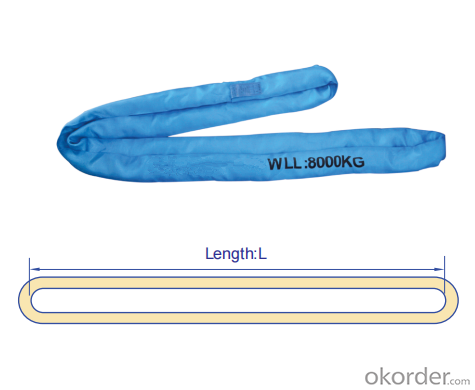

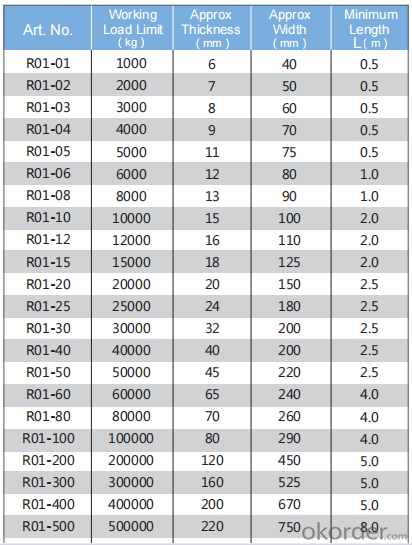

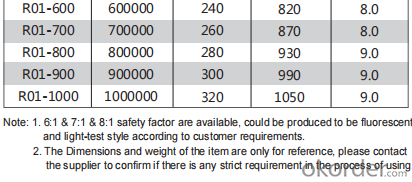

Heavy Duty Soft Round Lifting Endless type Textile Sling/Webbing Sling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

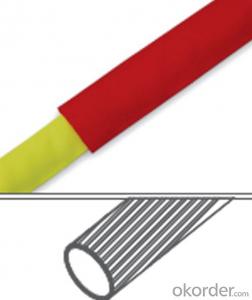

Heavy Duty Soft Round Lifting Endless type Textile Sling/Webbing Sling

Chracteristics:

Soft, light, no harm to the cargo, safety, long life and so on.

Light and soft, can be used in small narrow space.In PU processing, anti-abrasion is enhanced,Non-conductive, no danger of electric stroke.

Product usage :

Apply to oil pipelines, large diameter thin-walled pipe and products hoisting.

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

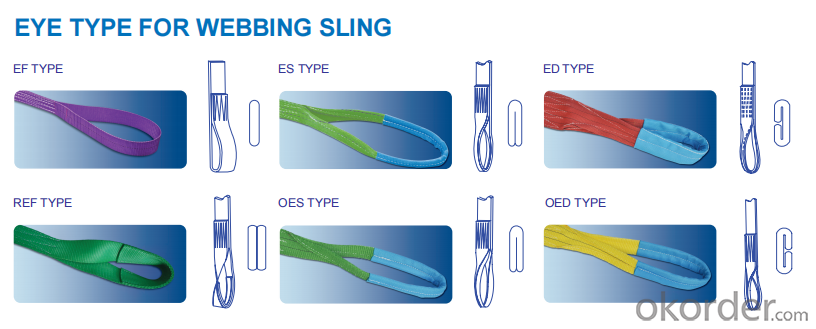

More Type:

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:5 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

- Q: Where should I pay attention to the formwork?

- (1) Kennedy to support part of the template and scaffold, when installed in the soil on the plate should be added, and the foundation must be solid and drainage measures of collapsible loess, there must be waterproof measures; frost heaving of soil is stopped, there must be anti freeze thaw measures.(2) in the course of installation of the formwork and its support, the temporary fixing equipment should be set up.

- Q: Is rope sling good business and high profit?

- With an annual output of 1 million 800 thousand tons of steel China ranked first in the world, is the first world phosphating wire rope wire rope surface treatment inhibited fretting fatigue to prolong the useful life (fatigue life), business wire rope and rigging, ordinary product profit, if can be linked to the manganese phosphating coating of steel wire rope, the profit is very high

- Q: What is the line on the train for?

- It's called catenary. There are two lines up and down. The upper part is called the load line, and the lower one is called the contact line. There is a sling connection between the cord and the contact wire.

- Q: What are the dangerous sections of the crane hook?

- The sling tension A-A section on the one hand, the hook has straightened trend; also by the effect of bending moment on the other hand. Because the moment in this section, the bending stress is maximum, this section is a dangerous section.

- Q: How much is the crane arm of the tower from the residential building recently?

- No aluminum conductor or steel shall be used as grounding or ground wire for the installation of tower cranes. A bolted wire must have an end. Grounding is mainly made up of the following three ways:1. the grounding body adopts a regular grounding pile, or a 33*4.5 long 1.5m steel tube, or a 70*70 long 1.5m angle steel.2. the floor is made of steel plates or other metal plates with an area of 1 square meters. The ground is deep from the ground 1.5m.3. a copper conductor with a cross-section of not less than 28 mm or a steel conductor with a cross section of not less than 50 mm is buried in the slot and its embedment length is determined by the grounding resistance.In the above three ways, the grounding body leads the copper conductor, the sectional area shall be no less than 25, if the soil is not conductive, the sodium chloride (salt) can be embedded in the soil. Then irrigation. For walking crane, each rail must be grounded, and the two tracks are connected by wires. Electrical connections should also be made between the two rails, with a resistance of no more than 4.

- Q: Requirements and matters needing attention in hoisting

- Hoisting tower tank by using rotary method or down method, wrist hinge at the bottom of the tower installation must have the ability level of the thrust generated resistance during lifting, the lifting process of the tower body around the ropes must be reliable, the tower height of the rotary position, slowly falling into the foundation, avoid accidents and deformation.

- Q: What's the sling for a movie?

- WIA, is used to protect the athlete's device is generally with a strong rope tied to the athlete's protection belt.

- Q: How do you tie the wire rope?

- The price of phosphating coating wire rope is higher than that of smooth steel wire rope, but the unit use cost is lower than the smooth steel wire rope. The test data indicate that fatigue life of phosphating coating steel wire rope is 3-4 times of plain steel wire rope, wire rope life and fatigue life is proportional to, according to the current market price of roughly wire rope, manganese phosphating coating of steel wire rope although the price is higher than that of plain steel wire rope, and prolonging the service life of much higher than the rate of price increase so, the phosphating coating steel wire rope, the average daily cost of using only smooth steel wire rope 30-45%, longer service life, lower cost per use, stability and security in the process of using and more cost-effective products, light surface wire rope upgrade, for reference only

- Q: What are the installation steps for crane beams?

- Installation of crane beam elevation as a negative deviation, between surface and column bracket crane beam flange into the iron plate. But the shim shall not exceed three layers and shall be placed under the end of the crane beam or under the stiffener, and the area of the shim shall not be less than 60% of the part of the contact area between the crane beam and the bracket.

- Q: Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- The cable-stayed bridge is a cable-stayed beam with a plurality of cable on the tower bridge. It consists of beam, cable and tower is composed of three parts. The cable-stayed bridge is a self anchored system, the level of power cable by Liang Chengshou, in addition to supporting beams on the pier, also supported by the cable leads to the tower. According to the materials used in the beam, they can be divided into steel cable-stayed bridge, composite beam cable-stayed bridge and concrete beam cable-stayed bridge.Cable stayed bridge is one of the most popular types of long-span bridges in china. So far, there are more than 3O cable-stayed bridges completed or under construction, second only to Germany and Japan, and the third place in the world. And the number of long-span concrete cable-stayed bridges has been ranked first in the world.In the middle of 50s, the first modern cable-stayed bridge was built in Sweden. For more than 40 years, the development of cable-stayed bridge has a strong momentum. In the middle of 70s, China began to build concrete cable-stayed bridges. After the reform and opening up, the momentum of the construction of cable-stayed bridges in China has been on the rise.

Send your message to us

Heavy Duty Soft Round Lifting Endless type Textile Sling/Webbing Sling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches