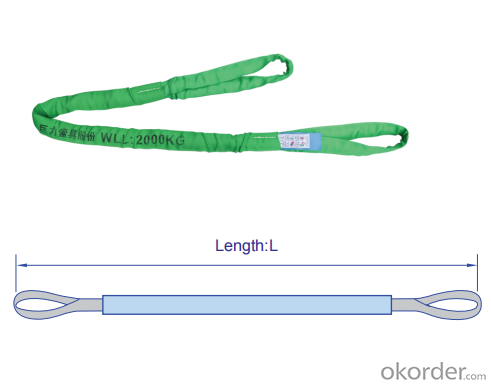

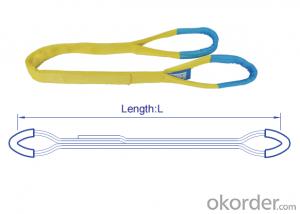

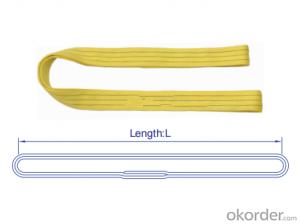

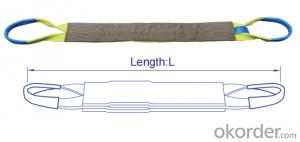

1000T Soft Webbing Sling Textile Endless Round Sling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

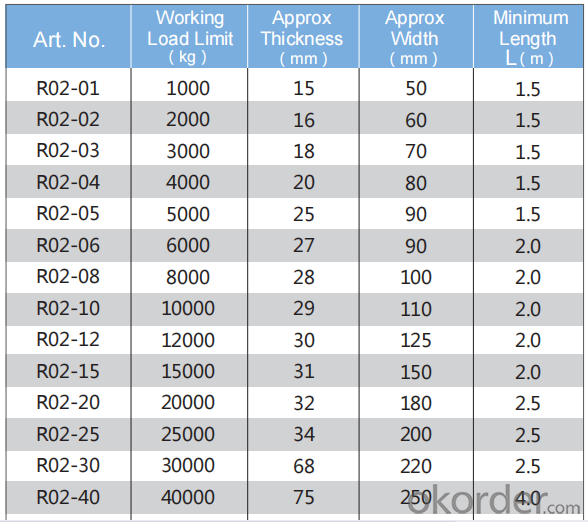

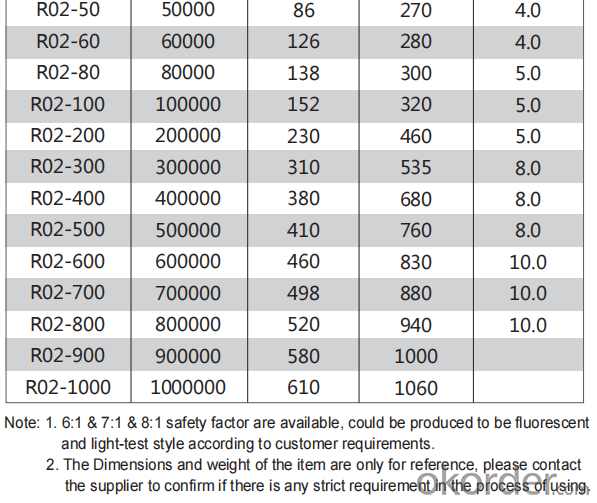

Specification

1000T Soft Webbing Sling Textile Endless Round Sling

Chracteristics:

Soft, light, no harm to the cargo, safety, long life and so on.

Light and soft, can be used in small narrow space.In PU processing, anti-abrasion is enhanced,Non-conductive, no danger of electric stroke.

Product usage :

Apply to oil pipelines, large diameter thin-walled pipe and products hoisting.

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

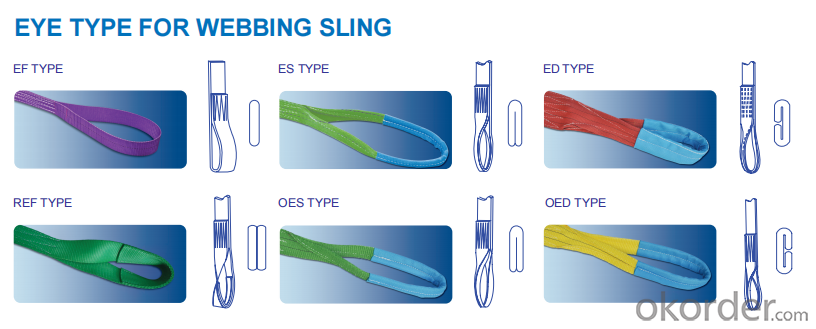

More Type:

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:5 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

- Q: What tools are slings in lifting operations? What is the function of the slings?

- Sling is one of the most common operation tools in hoisting operation.

- Q: What is the influence of lifting angle on rigging?

- The vertical lifting is the best scheme for lifting. The smaller the angle between the sling and the vertical is, the greater the angle is, the greater the force the sling will bear. The sling will be easily broken off, which will lead to an accident, which is for reference only

- Q: What is the line on the train for?

- It's called catenary. There are two lines up and down. The upper part is called the load line, and the lower one is called the contact line. There is a sling connection between the cord and the contact wire.

- Q: 20 tons sling rope, steel wire or chain?

- The main - phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope and coated steel wire rope wire rope varieties, for reference only

- Q: Which brand is better for imported rigging?

- CarlStahl set up Chinese branch in Hangzhou in 2006, mainly engaged in CarlStahl brand heavy duty crane, lifting fixture, spring balancer, hoist, crane beam, lift hook, rope, wire rope, tie, round sling hoisting products etc..

- Q: What torture refers to the lever and the sling

- This is a torture peculiar to china. The knee joint has the smallest range in the major joints of the limbs, and the length of both ends of the thigh and leg is favorable to the prisoners. The lever principle is used to compel the victims with lesser intensity. Key points of anti joint using tiger stool:1, the victims in the sitting position (arms tied or tied into the penalty, the pulling force cross) it will aggravate the leg ligament, and supine position due to hip joint ligament relaxation, legs relaxed, will weaken the degree of pain;2, the leg is tied in the lap of the thigh, rather than the following parts. Because the function of the tiger stool is to pull the joints and ligaments of the victim's leg and to cause a dislocated knee, not to break the victim's leg. Because the broken leg, the fibula needs a lot of power, the pain time is short (the victim will soon fainted), do not meet the punishment, both to torture the victims and their own labor saving requirements.According to records, when the victim is on a tiger stool, he usually gets sweaty when he pad three bricks. When the five bricks are completely dislocated, the person will faint. The torturer usually each brick will be suspended for a while, the victims of the pain continued for a period of time after aggravated torture efforts. Women's ligaments are usually softer than men, so they suffer longer on tiger stools and tend to faint when they are added to six bricks, the longest of which is eight bricks.

- Q: What are the precautions for rigging in hoisting works?

- The sling shall not be allowed to repair or reprocess itself (welding, heating, heat treatment, surface chemical treatment). If such treatment must be carried out, it shall be sent back to the original manufacturer or under the guidance of the experts of the original factory.

- Q: How do you tie the wire rope?

- The price of phosphating coating wire rope is higher than that of smooth steel wire rope, but the unit use cost is lower than the smooth steel wire rope. The test data indicate that fatigue life of phosphating coating steel wire rope is 3-4 times of plain steel wire rope, wire rope life and fatigue life is proportional to, according to the current market price of roughly wire rope, manganese phosphating coating of steel wire rope although the price is higher than that of plain steel wire rope, and prolonging the service life of much higher than the rate of price increase so, the phosphating coating steel wire rope, the average daily cost of using only smooth steel wire rope 30-45%, longer service life, lower cost per use, stability and security in the process of using and more cost-effective products, light surface wire rope upgrade, for reference only

- Q: What are the installation steps for crane beams?

- The crane beam and track shall be corrected after the main component is fixed. Fix immediately after correction, in order of fixation, bolt first and then weld.

- Q: What are the specifications for the length, length, and method of operation of the wire rope?

- Users need high quality steel wire rope, it should be long life and high quality stable and reliable wire rope.

Send your message to us

1000T Soft Webbing Sling Textile Endless Round Sling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches