GALVANIZED STEEL WIRE ROPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: What is the line on the train for?

- It's called catenary. There are two lines up and down. The upper part is called the load line, and the lower one is called the contact line. There is a sling connection between the cord and the contact wire.

- Q: 20 tons sling rope, steel wire or chain?

- The strength of the steel wire rope can reach 2000-2500MPa, and is made by using cold drawn steel wire. The tensile strength is much higher than that of the chain, so that the weight of the sling can be reduced, the production efficiency can be higher, and the steel wire rope is preferred.

- Q: What is the name of the wire above the train?

- It's called catenary. There are two lines up and down. The upper part is called the load line, and the lower one is called the contact line. There is a sling connection between the cord and the contact wire.

- Q: Why do not different kinds or different sizes of slings and slings are used together?

- Choose proper slings and slings according to the specific conditions of the heavy loads; no heavy weights are allowed to be attached directly with the hooks, and no different kinds are allowed

- Q: Ceiling installation does not allow the use of air nails?

- Connection of hanging cup, sling and structural layerOperation method: (1) the main consideration connected with embedded parts and transition piece.In the first layer in embedded iron or wood brick (except water brick). The location shall be accurate and adequate adjustment should be made.The transition in the iron and wooden fittings, so as to adjust the mindware error, and mindware nail, screw, welding, wear.The suspender and the sling are connected with the transition connecting piece.

- Q: How do you tie the wire rope?

- Manganese phosphating belongs to wear, corrosion, phosphating, automobile transmission, steel gear is through the manganese phosphating treatment, can ensure that the car gear for more than ten years without damage. Phosphating coating of steel wire rope China patent technology production, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just add the last bonderizing process, steel wire for rope wear resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope. The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of domestic smooth steel wire rope, wire rope surface is 2-3 times of imports, (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility, is currently the most advanced technology in the world of steel wire rope field. Manganese phosphating is bonderizing, can solve the problem of wire rope wear during use, smooth wire rope being eliminated, because the phosphating coating steel wire rope in short supply, the more sought after, need to ask a few companies.

- Q: What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 3. stainless steel wire rope, the use of stainless steel wire rope system, such as 304 or 316 stainless steel, the price is relatively expensive, the stainless steel wire for manganese phosphating coating (stainless steel wire need special phosphating phosphating formula), you can use the same life greatly extended.

- Q: Notice of tower crane?

- The metal structure of the tower crane, the track and the metal shell of all the electrical equipment shall have reliable earthing devices, and the grounding resistance shall not be greater than 4 ohms, and lightning protection devices shall be set up.Fourth. Pole arrangement, each attachment device attached to the wall and spaced distance should be in accordance with the provisions of the original factory, homemade bar design calculations should be.

- Q: Does the pressing rope have any influence on the tension value of the wire rope?

- According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q: Types of slings for slings

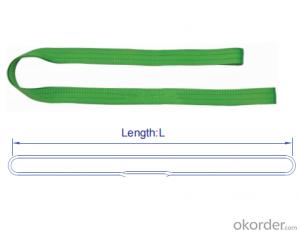

- Synthetic fiber slings are mainly made of nylon, polypropylene, polyester, high-strength and high modulus polyethylene fiber for rope and belt slings.

Send your message to us

GALVANIZED STEEL WIRE ROPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords